Optical thin film LIDT (laser induced damage threshold) testing device and method based on light scattering

A technology of optical thin film and testing device, which is applied in the field of optical testing, can solve the problem that the laser damage threshold test of the optical element film layer cannot quickly and efficiently adapt to the requirements of enterprise assembly line, so as to save testing cost, solve inaccurate problems, and improve measurement accuracy. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

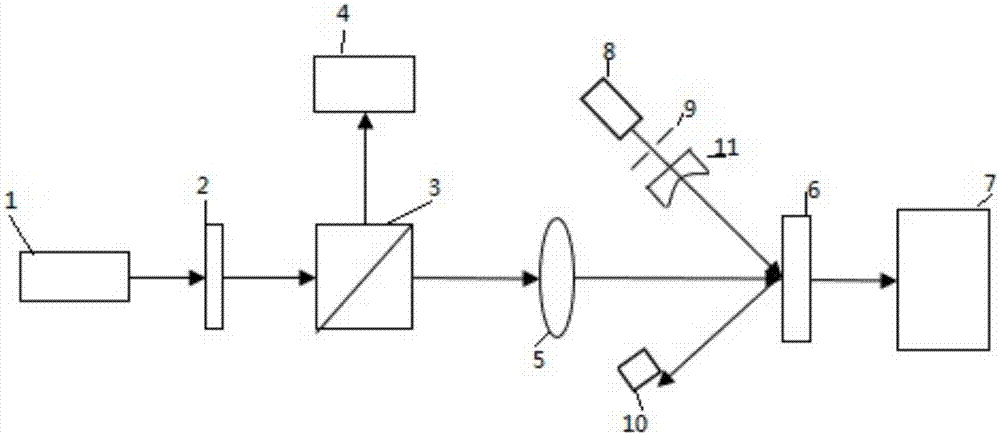

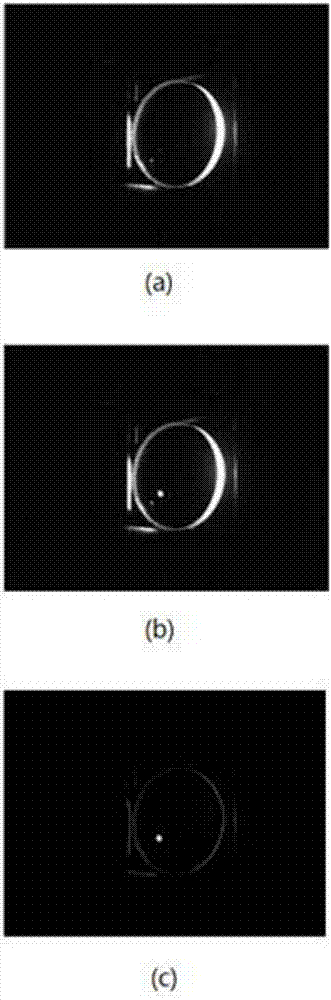

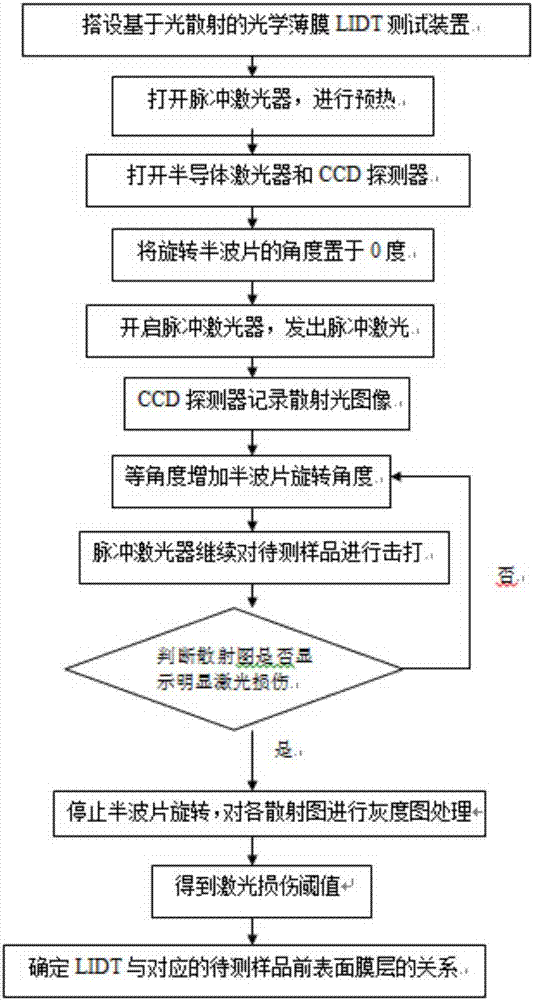

[0043] The technical solution adopted in the present invention is to irradiate the CCD detector 10 with scattered light, and to process and analyze the grayscale image of the obtained image: starting from two aspects of non-contact measurement and image processing, the optical thin film is improved in the pulsed laser The judgment accuracy of the damage threshold value under the impact; first place the sample 6 to be tested on the deck to ensure that the laser light is perpendicular to the film surface of the sample 6 to be tested; then change the angle of the half-wave plate 2 to change the laser pulse of the pulse laser 1 The angle of incidence is used to obtain the damage on the surface of the sample 6 film to be tested under different intensities of laser light; another semiconductor laser 8 is used to irradiate the front surface of the sample 6 to be tested, and the CCD detector 10 collects the LIDT scattered light of the sample 6 film to be tested under different laser int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com