Portable catalytic combustion bed

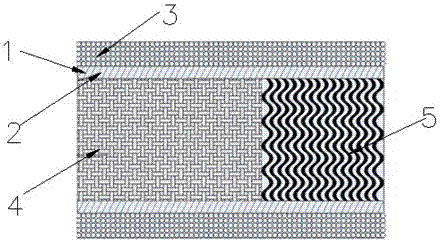

A catalytic combustion bed, portable technology, applied in the combustion method, combustion type, chemical elements of heterogeneous catalysts, etc., can solve the problem of low temperature, the heating time needs more than 30 minutes, the problem of explosion and explosion is easy to occur, and the floor space is large, etc. problem, to achieve the effect of low cost, light weight and small wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The honeycomb molecular sieve adsorption material is made of silicon-aluminum material, which is connected by silicon-oxygen tetrahedron or aluminum-oxygen tetrahedron through oxygen bridge bonds to form a molecular-sized pore and cavity system. The material composition is by weight ratio: silicon dioxide: trioxide Two aluminum is 300.

[0024] The metal foam catalyst component includes 5 parts of titanium dioxide, 1 part of silicon dioxide, 5 parts of cerium oxide, 5 parts of activated alumina, 0.03 parts of precious metal platinum and palladium and 60 parts of foam metal in parts by weight.

[0025] The usage method of this embodiment includes the following steps:

[0026] A. The pre-treated gas enters the inner cavity of the shell, and the low-concentration VOCs gas is passed into the equipment. The honeycomb molecular sieve adsorption material in the equipment can be adsorbed and concentrated, so that the treated gas reaches the national standard and then discharged...

Embodiment 2

[0030] The honeycomb molecular sieve adsorption material is made of silicon-aluminum material, which is connected by silicon-oxygen tetrahedron or aluminum-oxygen tetrahedron through oxygen bridge bonds to form a molecular-sized pore and cavity system. The material composition is by weight ratio: silicon dioxide: trioxide Two aluminum is 400.

[0031] The metal foam catalyst component includes 10 parts of titanium dioxide, 5 parts of silicon dioxide, 10 parts of cerium oxide, 10 parts of activated alumina, 0.1 parts of precious metal platinum and palladium and 80 parts of foam metal in parts by weight.

[0032] The usage method of this embodiment includes the following steps:

[0033] A. The pre-treated gas enters the inner cavity of the shell, and the low-concentration VOCs gas is passed into the equipment. The honeycomb molecular sieve adsorption material in the equipment can be adsorbed and concentrated, so that the treated gas reaches the national standard and then dischar...

Embodiment 3

[0037] The honeycomb molecular sieve adsorption material is made of silicon-aluminum material, which is connected by silicon-oxygen tetrahedron or aluminum-oxygen tetrahedron through oxygen bridge bonds to form a molecular-sized pore and cavity system. The material composition is by weight ratio: silicon dioxide: trioxide Two aluminum is 300.

[0038] The metal foam catalyst component includes 6 parts of titanium dioxide, 2 parts of silicon dioxide, 6 parts of cerium oxide, 6 parts of activated alumina, 0.05 parts of precious metal platinum and palladium and 65 parts of foam metal in parts by weight.

[0039] The usage method of this embodiment includes the following steps:

[0040] A. The pre-treated gas enters the inner cavity of the shell, and the low-concentration VOCs gas is passed into the equipment. The honeycomb molecular sieve adsorption material in the equipment can be adsorbed and concentrated, so that the treated gas reaches the national standard and then discharge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com