Vehicle-mounted wireless charging base vibration power generation device with high power generation efficiency

A technology of vibration power generation and on-board wireless, which is applied in the direction of electromechanical devices, machines/engines, electrical components, etc., can solve the problems of space limitation, small conductor movement range, low power generation efficiency, etc., and achieve good scalability, small size, and improved power generation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

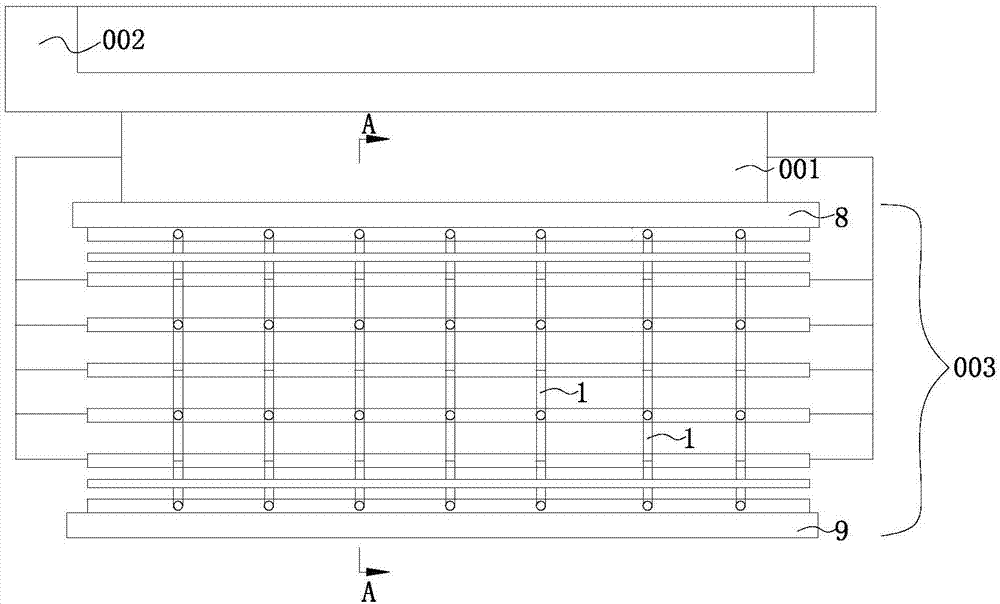

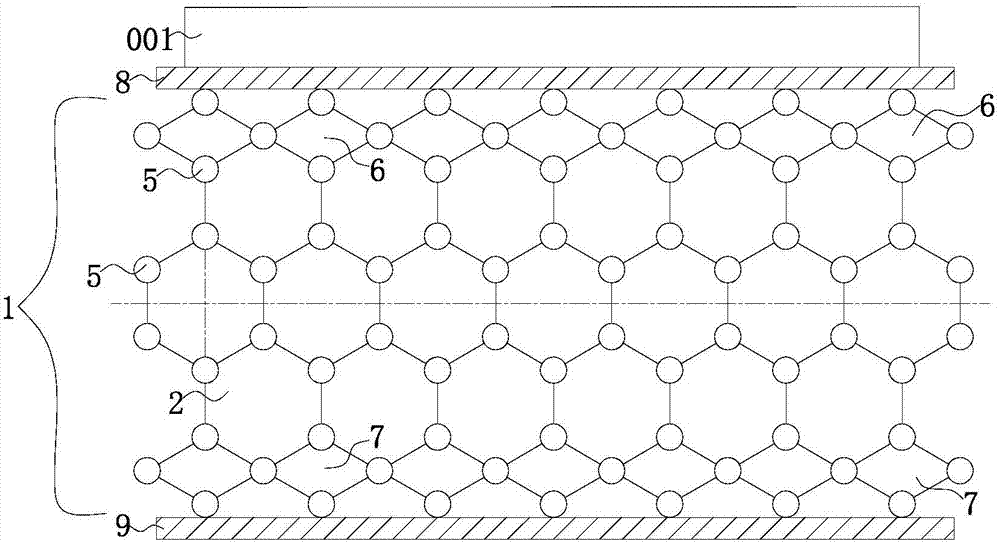

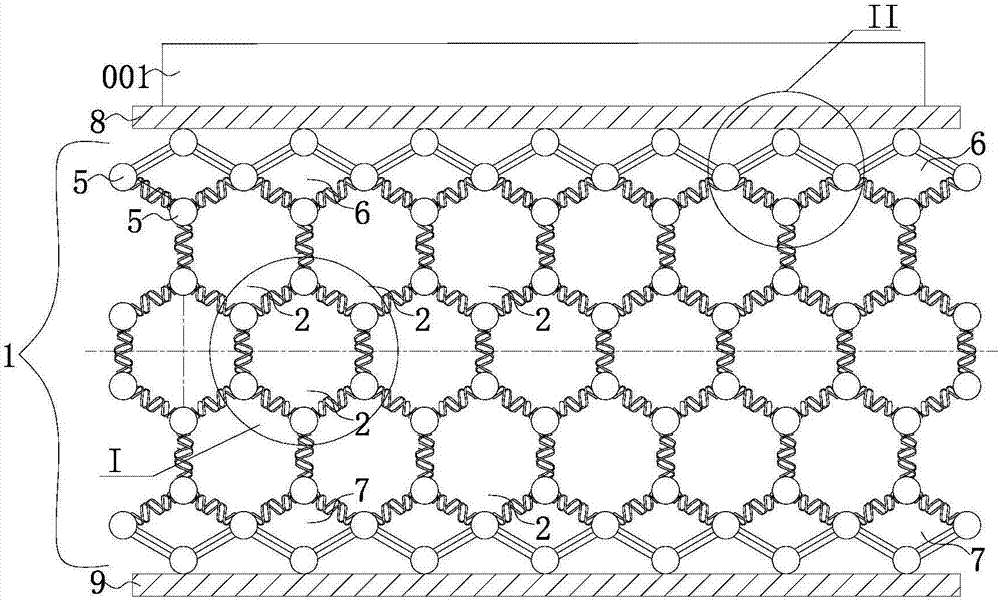

[0037] like Figure 1-Figure 14Shown is a vehicle-mounted wireless charging station vibration power generation device with high power generation efficiency. The upper surface of the flat vibration power generation device 003 is connected to the lower surface of the substrate battery 001, which can be bonded, snap-fit or otherwise Connection, the lower surface of the vibration power generation device 003 forms a detachable connection with the car body; it can be a buckle connection, a bolt connection, or other detachable connections; the substrate battery 001 can be a whole The lithium battery board can also be a flat structure formed by splicing a plurality of rectangular lithium battery units, or a flat structure in which a plurality of capsule-shaped rechargeable batteries are in contact with each other and arranged in parallel. The upper surface of the substrate battery 001 is provided with a wireless The charging stand 002, the substrate battery 001 and the wireless char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com