Automobile exhaust pipe

A technology for automobile exhaust and exhaust pipes, which is applied in exhaust treatment, exhaust devices, coatings, etc., can solve problems such as environmental pollution and poor heat insulation effect of exhaust pipes, and achieve reasonable product structure design and improvement. The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

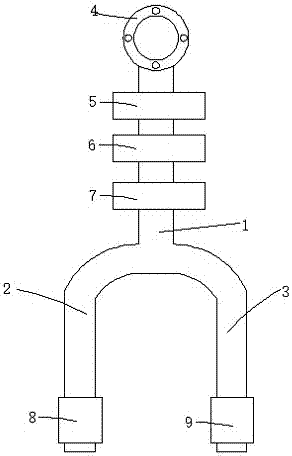

[0028] see Figure 1 to Figure 2 , the present invention provides an automobile exhaust pipe, comprising: a main exhaust pipe 1, a first branch exhaust pipe 2 and a second branch exhaust pipe 3 communicated with the first end of the main exhaust pipe 1, and The mounting flange 4 connected to the second end of the main exhaust pipe 1, the first filter 5, the three-way catalytic converter 6 and the second filter arranged in sequence along the exhaust gas discharge direction on the main exhaust pipe 1 A filter 7, and a first muffler 8 and a second muffler 9 respectively arranged on the first branch exhaust pipe 2 and the second branch exhaust pipe 3;

[0029] The first filter 5 is filled with filter cotton, and the second filter 7 is filled with activated carbon;

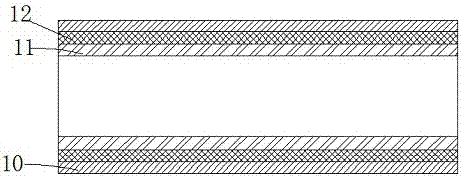

[0030] The main exhaust pipe 1, the first branch exhaust pipe 2 and the second branch exhaust pipe 3 all include: an outer pipe 10, an inner pipe 11 located inside the outer pipe 10, and an inner pipe 11 located insid...

Embodiment 2

[0035] A method for processing a filter assembly of an automobile exhaust pipe, the steps are as follows:

[0036] ①, structure and molding

[0037] The filter assembly includes a first filter, a three-way catalytic converter and a second filter arranged in sequence along the exhaust gas emission direction, the first filter is filled with filter cotton, and the second filter is filled with activated carbon;

[0038] The three-way catalytic converter is prepared according to the prior art;

[0039] Both the first filter and the second filter include a shell and a filler placed in the shell, the filter silk cotton and activated carbon are prepared according to the prior art, and the shell is forged from carbon steel;

[0040] ②, Pretreatment of the shell inner wall of the first filter and the second filter

[0041] Spray the pretreatment liquid on the inner wall of the housing of the first filter and the second filter, and dry it directly after spraying;

[0042] The componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com