Novel multi-functional floor drain structure and construction method thereof

A construction method and multi-functional technology, applied to drainage structures, waterway systems, buildings, etc., can solve problems such as poor waterproof effect, inability to remove, musty smell in bathrooms, etc., to prevent wall moisture or water permeability, and solve The effect of maintenance on the same floor and large drainage flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with specific examples.

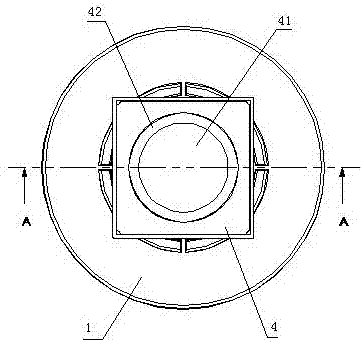

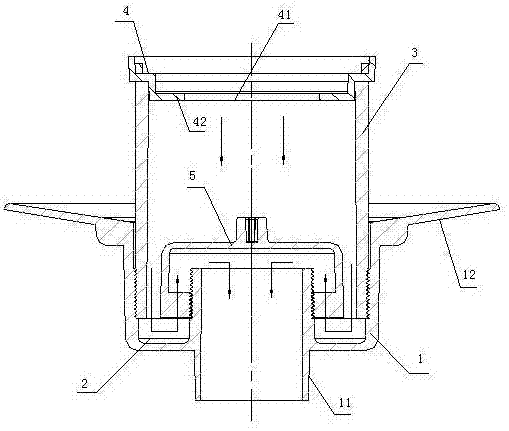

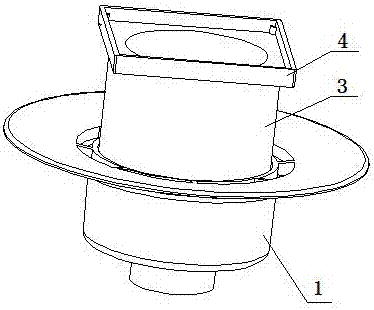

[0021] Such as Figure 1-6 As shown, the new multifunctional floor drain structure includes a floor drain main body 1, a downpipe 11 is arranged in the middle of the bottom of the main body 1, and a sedimentation area 2 is formed on the outside of the downpipe 11. On the main body 1, the height of the bracket 3 can be adjusted through threads. There is a floor drain cover tray 4 on the top of the bracket 3, and there is a drain port 41 in the middle of the floor drain cover tray 4. The upper end of the main body extends outwards to form an inclined guide edge 12. The outer wall of the upper part of the drain pipe 11 has threads, and the lower part of the deodorant cover 5 has 4 inwards. The protrusion 51 has threads on the upper surface of the protrusion 51 to match the threads on the outer wall of the upper part of the downpipe 11 to fix the deodorizing cover 5 on the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com