Gradient cemented carbide with gradient change of binder phase and preparation method thereof

A cemented carbide, gradient change technology, applied in mining column teeth and oil column teeth, can solve problems such as unstable performance, and achieve the effects of good product consistency, good wear resistance and low cobalt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Example: A Gradient Cemented Carbide with Gradient Binder Phase and Its Preparation Method

[0049] The preparation method comprises the steps in turn:

[0050] The first step is to prepare alloy mixture, which includes WC powder and Co powder, and the preparation process is as follows:

[0051] (1) Add WC powder and Co powder, mix evenly to form WC-Co powder, in which, the mass percentage of WC powder is 89%, the mass percentage of Co powder is 11%, and the WC-Co powder The sample can be abbreviated as WC-11% Co or 89%WC-11%Co;

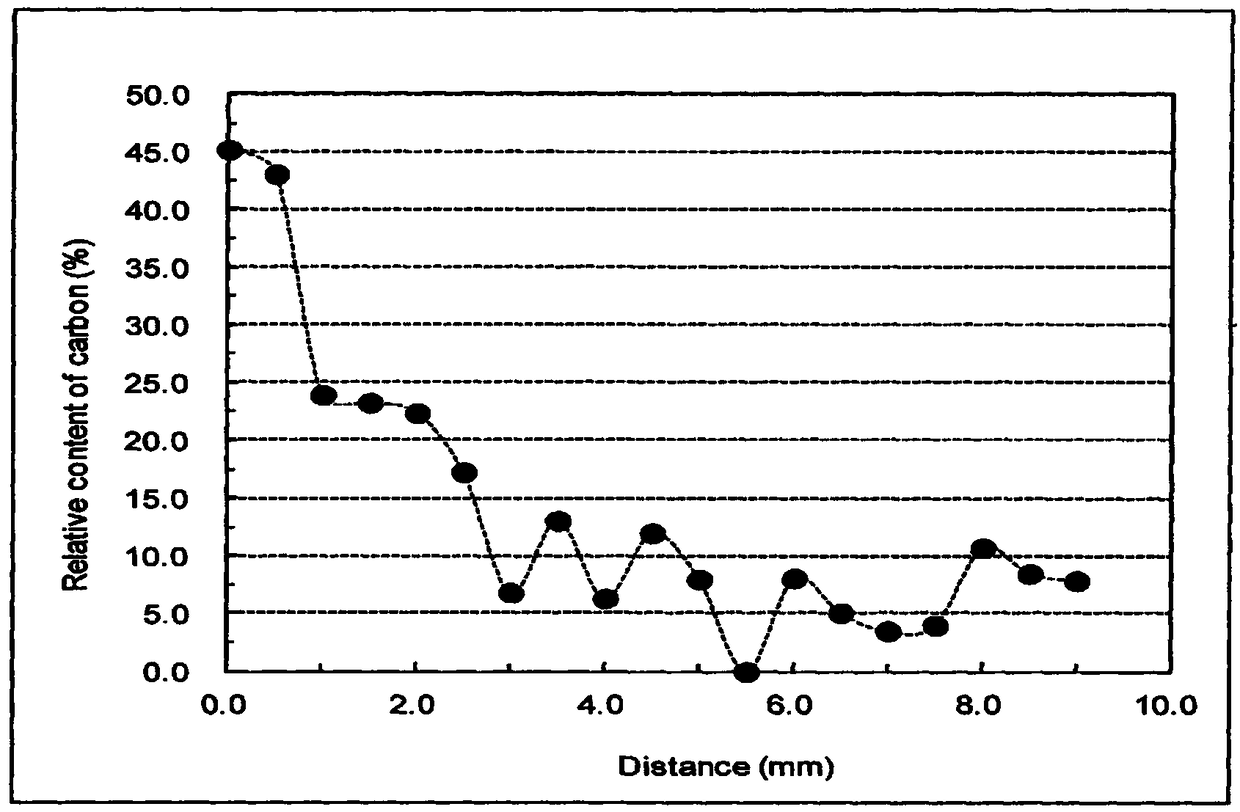

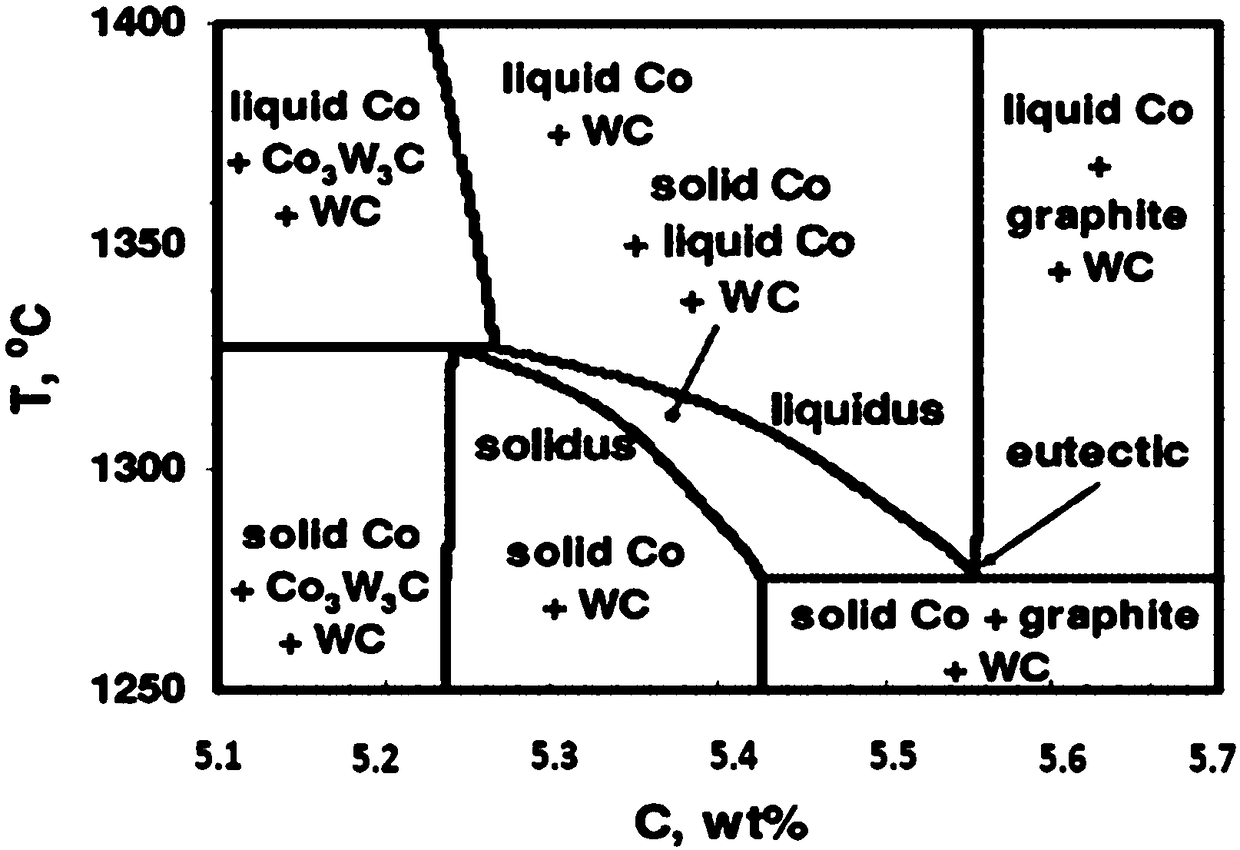

[0052] (2) Add carbon powder or tungsten powder to adjust the carbon content of the WC-Co powder. The carbon content of the WC-Co powder is calculated in substoichiometric equivalents, and the upper limit of the carbon content is 6.125%×(1-Co%). The lower limit of content is 6.130%×(WC%-Co%×0.26); the carbon content of WC-Co powder affects the concentration distribution of cobalt content.

[0053] Table 1 WC-Co compositions of different car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com