Processing method of dust-suppression sludge curing agent

A processing method and curing agent technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, sludge treatment, etc., can solve problems such as agglomeration and pilling, curing agent failure, etc., and achieve good dispersibility, wetting Good permeability and the effect of expanding the choice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

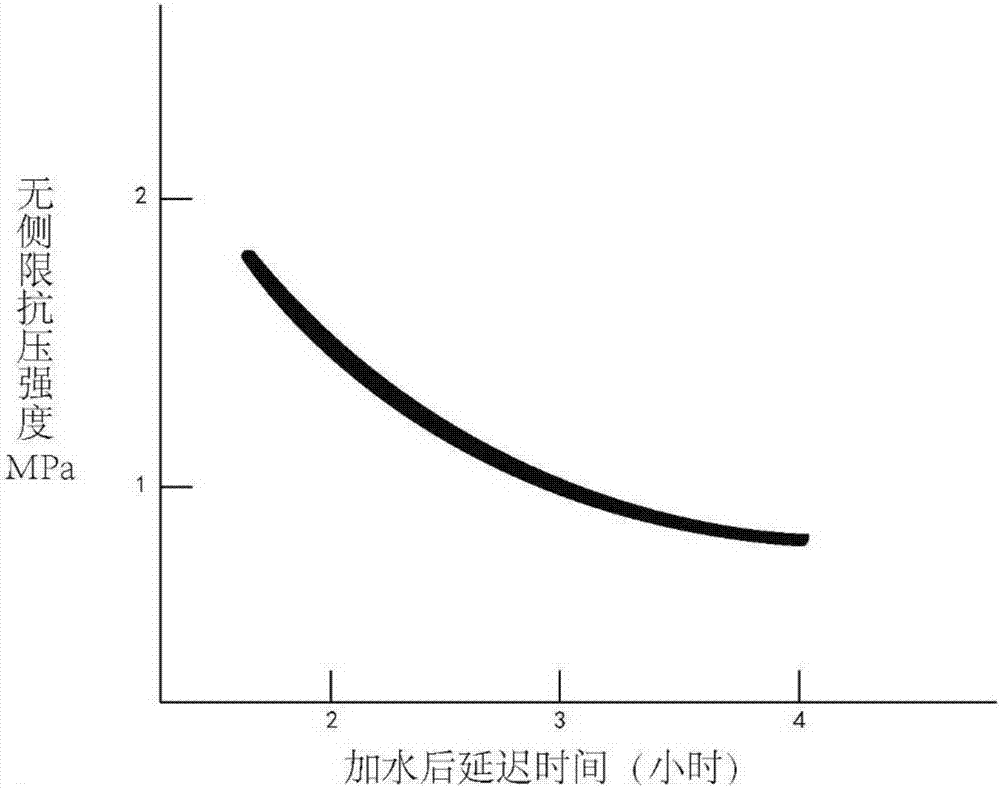

[0035] Example 1: Effect of Delay Time of Humidified Curing Agent on Unconfined Compressive Strength

[0036] Silt from Haixu Road, Sino-Singapore Tianjin Eco-city, with a moisture content of 89% and a wet density of 1.45g / cm 3 , the green belt solidification soil strength design site is 0.3Mpa, and the subgrade solidification design value site is 0.4Mpa; Carry out the influence of the delay time of humidification curing agent on the unconfined compressive strength in the laboratory, the curing agent used is embodiment 2 in CN101081718A Middle curing agent:

[0037] Sodium α-olefin sulfonate, nonylphenol polyoxyethylene ether and water are formulated into an aqueous surfactant solution, wherein the mass percentage of alpha-olefin sulfonate sodium is 0.05%, and the mass percentage of nonylphenol polyoxyethylene ether is 0.01% , The balance is tap water. The addition amount of the surfactant aqueous solution is 8% of the weight of the curing agent, and the usage amount of the ...

Embodiment 2

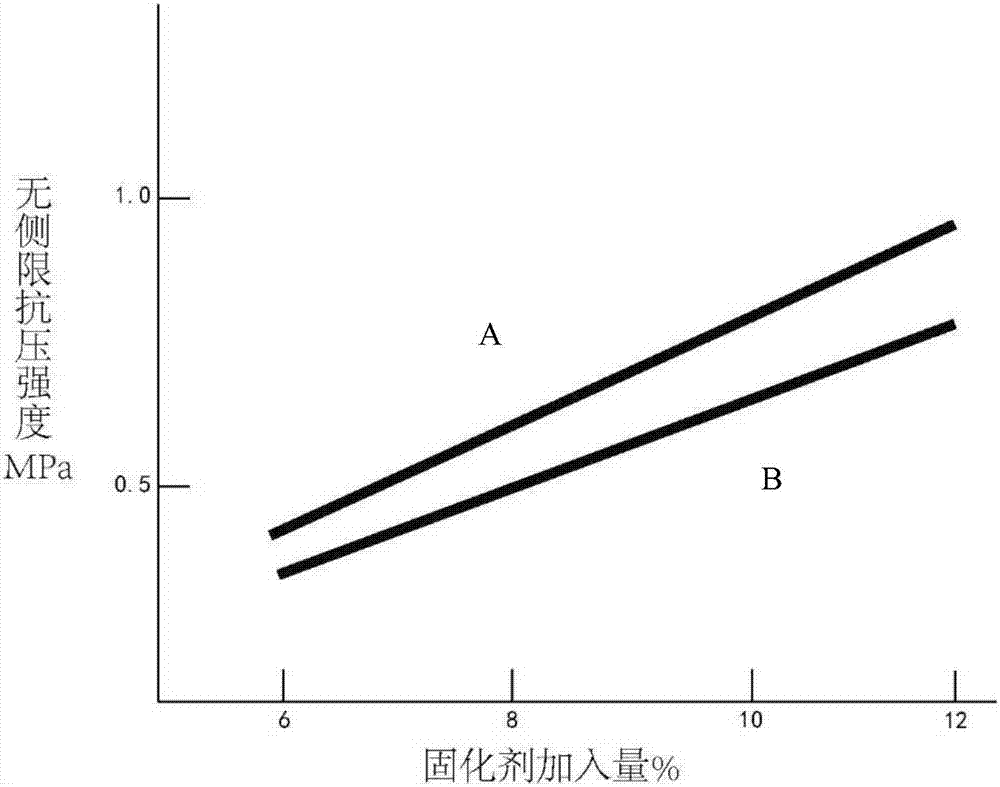

[0039] Example 2: The effect of humidified curing agent and the amount of curing agent used on the unconfined compressive strength

[0040] Humidification curing agent is used for the consolidation of the silt in the east (li) embankment of Sino-Singapore Tianjin Eco-city, the moisture content of the silt is 67%, and the wet density is 1.64g / cm 3 .

[0041]Sodium α-olefin sulfonate and water are prepared into an aqueous surfactant solution, wherein the mass percentage of sodium α-olefin sulfonate is 0.1%, and the balance is tap water. The curing agent in Example 2 in CN101081718A is placed in a double-helix mixer, and then the surfactant aqueous solution is sprayed into the double-helix mixer, and stirred while spraying, so that the curing agent is humidified evenly, thereby obtaining a humidification curing agent; surface active The addition of the aqueous solution of the curing agent is 8% of the weight of the curing agent. Put the humidifying and curing agent on an ordina...

Embodiment 3

[0045] Sino-Singapore Tianjin Eco-city Dongdi Road silt consolidation adopts humidification and curing agent, the moisture content of the silt is 67%, and the wet density is 1.64g / cm 3 .

[0046] Sodium α-olefin sulfonate and water are prepared into an aqueous surfactant solution, wherein the mass percentage of sodium α-olefin sulfonate is 0.1%, and the balance is tap water. The curing agent of Example 3 in CN101081718A is placed in a double-helix mixer, and then the surfactant aqueous solution is sprayed into the double-helix mixer, and stirred while spraying, so that the curing agent is humidified evenly, thereby obtaining a humidification curing agent; surfactant The added amount of aqueous solution is 8% of curing agent weight. Put the humidifying and curing agent on an ordinary light truck, cover it with a tarpaulin, transport it to the destination, and pour it directly on the mud. The usage of the humidifying and curing agent is 9% of the weight of the mud; then use the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com