Phosphogypsum pretreatment system

A pretreatment and phosphogypsum technology, which is applied in the field of building materials, can solve problems such as high internal moisture content, low moisture content, and secondary pollution, and achieve the effects of maintaining stable production capacity, reducing moisture content, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

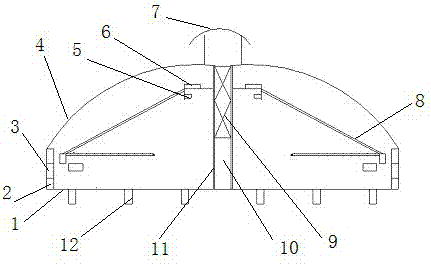

[0008] In order to further illustrate the technical scheme of the present invention, now in conjunction with accompanying drawing, illustrate the specific implementation manner of the present invention; figure 1 In this example, the length of wall 2 is 100,000 mm, the height of wall 2 is 3,000 mm, the thickness of wall 2 is 500 mm, and the distance between walls 2 on both sides is 32,000 mm. The entrances and exits and doors are installed on the walls 2 at both ends; Lay with cement mortar; on the fence 2, set the opening with a width of 1500 mm and a height of 1000 mm with a shutter that can be opened and closed at a distance of 500 mm from the ground as the air inlet 3. In this example, the air inlet 3 is selected to be spaced along the length of the fence 2 10,000 mm is evenly covered with the wall 2; the glass curtain wall supported by steel structure is used as the ceiling 4, the two ends of the ceiling 4 are connected with the wall 2, and the middle part is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com