Membrane type brackish water softening method based on magnetic pretreating technology

A brackish water, pretreatment technology, applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., can solve the problem of deposition on pipe walls or magnets, aggravate membrane surface pollution, and increase the risk of membrane process operation. and other problems, to achieve the effect of good effluent quality, reduction of chemical cleaning times, considerable economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

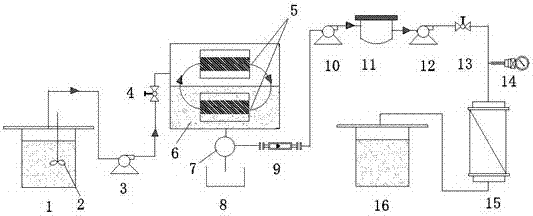

[0025]The bicarbonate-sulphate type brackish water sample at the junction of the North China piedmont alluvial plain and the central alluvial plain was drawn into the stainless steel water inlet tank, and the TDS and pH values of the brackish water were 1000 mg·L, respectively. −1 and 6.80, Ca 2+ , Mg 2+ , SO 4 2− 、HCO 3 − Concentrations are 70mg·L −1 , 40mg·L −1 , 106mg·L −1 and 112mg·L −1 . The 5 groups of magnetic processing units corresponding to the upper and lower sides are arranged correspondingly along the axis. The magnetic material of the magnetic processing unit is permanent magnet material. The yoke is made of soft iron, A3 steel or soft magnetic alloy with relatively high magnetic permeability, and the gap is filled with stainless steel. The diameter of wool and steel wool is 30 μm, the filling rate is 2%, the average magnetic field strength of the entire magnetic field area is 0.86T, so that the incoming water circulates in the upper and lower magnetic...

Embodiment 2

[0027] The bicarbonate-sulphate type brackish water sample at the junction of the North China piedmont alluvial plain and the central alluvial plain is drawn into the stainless steel water inlet tank, and the TDS and pH values of the brackish water are 4000mg·L respectively −1 and 9.50, Ca 2+ , Mg 2+ , SO 4 2− 、HCO 3 − Concentrations are 150mg·L −1 , 80mg·L −1 , 300mg·L −1 and 350mg·L −1 . The 10 groups of magnetic processing units corresponding to the upper and lower sides are arranged correspondingly along the axis. The magnetic processing unit can be made of soft magnetic materials. This type of magnetic material has high magnetic permeability and magnetic induction intensity. The loss should be small. The yoke can be made of an alloy with a relatively high magnetic permeability, and the gap is filled with filamentous or mesh-like magnetic gathering material or steel wool with a diameter of 10 μm, the filling rate is 10%, and the average magnetic field strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com