Method for preparing mesoporous Alpha-Fe2O3/Alpha-Al2O3 and magnetic mesoporous Gamma-Fe2O3/Alpha-Al2O3 nanoscale composite materials under low-temperature condition

A nanocomposite material, low temperature technology, applied in the field of inorganic nanomaterials, can solve the problems of uneven particle size, difficult preparation, complicated process, etc., and achieve the effects of uniform pore size distribution, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a mesoporous α-Fe under low temperature conditions 2 o 3 / α-Al 2 o 3 and magnetic mesoporous γ-Fe 2 o 3 / α-Al 2 o 3 A method for preparing a nanocomposite material, comprising the steps of:

[0031] a. A certain amount of aluminum nitrate nonahydrate is dissolved in deionized water;

[0032] b. At 70°C, add ammonium carbonate solution under the condition of stirring, control the volume of ammonium carbonate, so that the amount of ammonium carbonate is 1.5 times the sum of the amount of aluminum ions; the gel is obtained through reaction;

[0033] c. Aging the gel formed after titration at a constant temperature of 30°C for 24 hours, then transferring to an oven and drying at 100°C for 12 hours;

[0034] d. Calcining the dried gel at 800°C for 10 hours at a heating rate of 2°C / min to prepare mesoporous γ-Al 2 o 3 Complex;

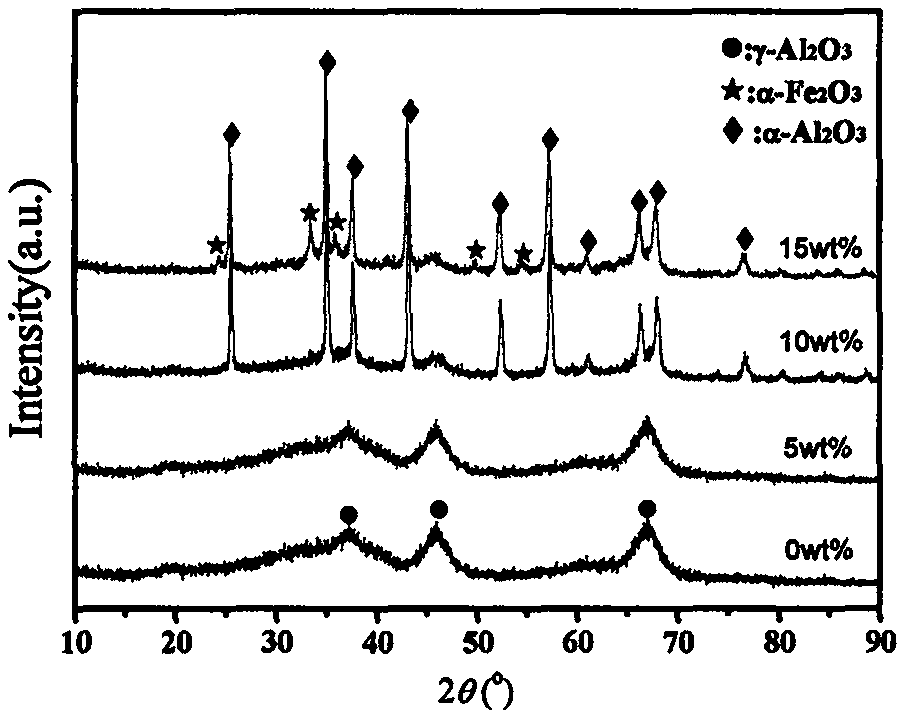

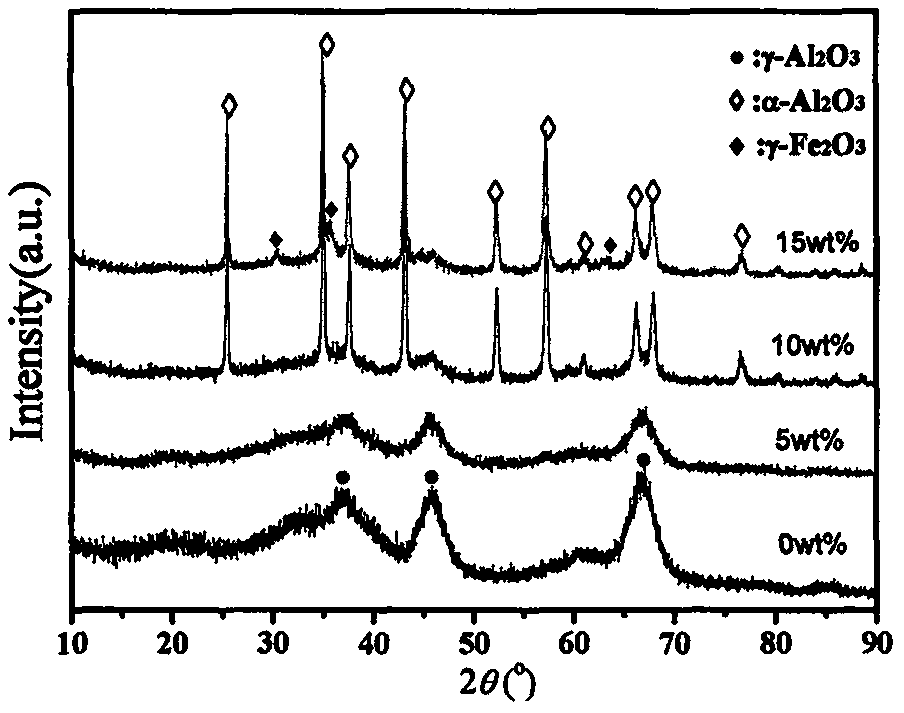

[0035] With the product of this example, carry out XRD collection of patterns to measure, and N 2 Determination ...

Embodiment 2

[0037] This embodiment provides a mesoporous α-Fe under low temperature conditions 2 o 3 / α-Al 2 o 3 and magnetic mesoporous γ-Fe 2 o 3 / α-Al 2 o 3 A method for preparing a nanocomposite material, comprising the steps of:

[0038] a. a certain amount of aluminum nitrate nonahydrate and ferric nitrate nonahydrate are dissolved in deionized water; the final obtained Fe 2 o 3 The mass of Fe 2 o 3 and Al 2 o 3 5% of the total mass;

[0039] b. At 70°C, add ammonium carbonate solution under stirring conditions, control the volume of ammonium carbonate, so that the amount of ammonium carbonate is 1.5 times the sum of the amount of iron and aluminum ions; the gel is obtained through reaction;

[0040] c. Aging the gel formed after titration at a constant temperature of 30°C for 24 hours, then transferring to an oven and drying at 100°C for 12 hours;

[0041] d. Calcining the dried gel at 800°C for 10 hours at a heating rate of 2°C / min to prepare mesoporous α-Fe 2 o 3 ...

Embodiment 3

[0045] This embodiment provides a mesoporous α-Fe under low temperature conditions 2 o 3 / α-Al 2 o 3 and magnetic mesoporous γ-Fe 2 o 3 / α-Al 2 o 3 A method for preparing a nanocomposite material, comprising the steps of:

[0046] a. a certain amount of aluminum nitrate nonahydrate and ferric nitrate nonahydrate are dissolved in deionized water, so that the final obtained Fe 2 o 3 The mass of Fe 2 o 3 and Al 2 o 3 10% of the total mass;

[0047] b. At 70°C, add ammonium carbonate solution under stirring conditions, control the volume of ammonium carbonate, so that the amount of ammonium carbonate is 1.5 times the sum of the amount of iron and aluminum ions; the gel is obtained through reaction;

[0048] c. Aging the gel formed after titration at a constant temperature of 30°C for 24 hours, then transferring to an oven and drying at 100°C for 12 hours;

[0049] d. Calcining the dried gel at 800°C for 10 hours at a heating rate of 2°C / min to prepare mesoporous α-Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com