Parallel fork clamp

A clamp rod and clamp body technology, which is applied in the field of thermal processing auxiliary tools, can solve the problems of tilting and sliding of the tray or bracket, insufficient contact area between the clamp and the tray, and inability to stably clamp the tray or bracket. The effect of a large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

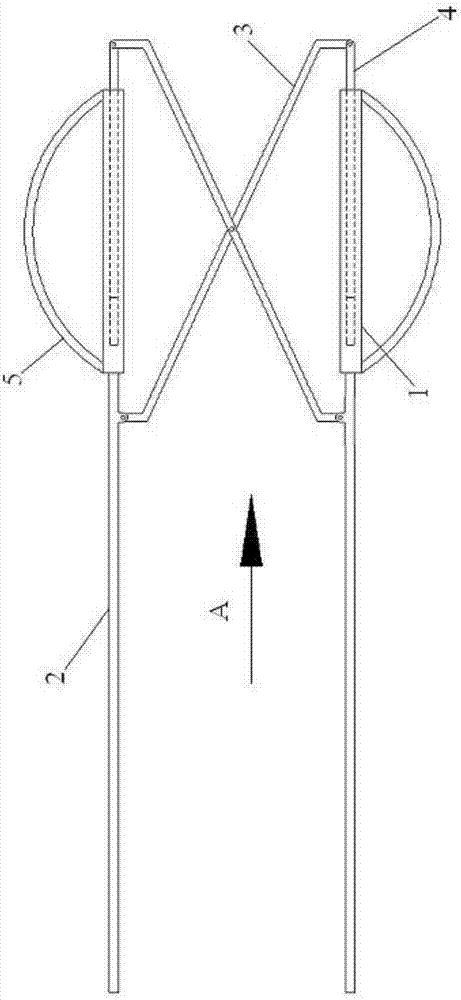

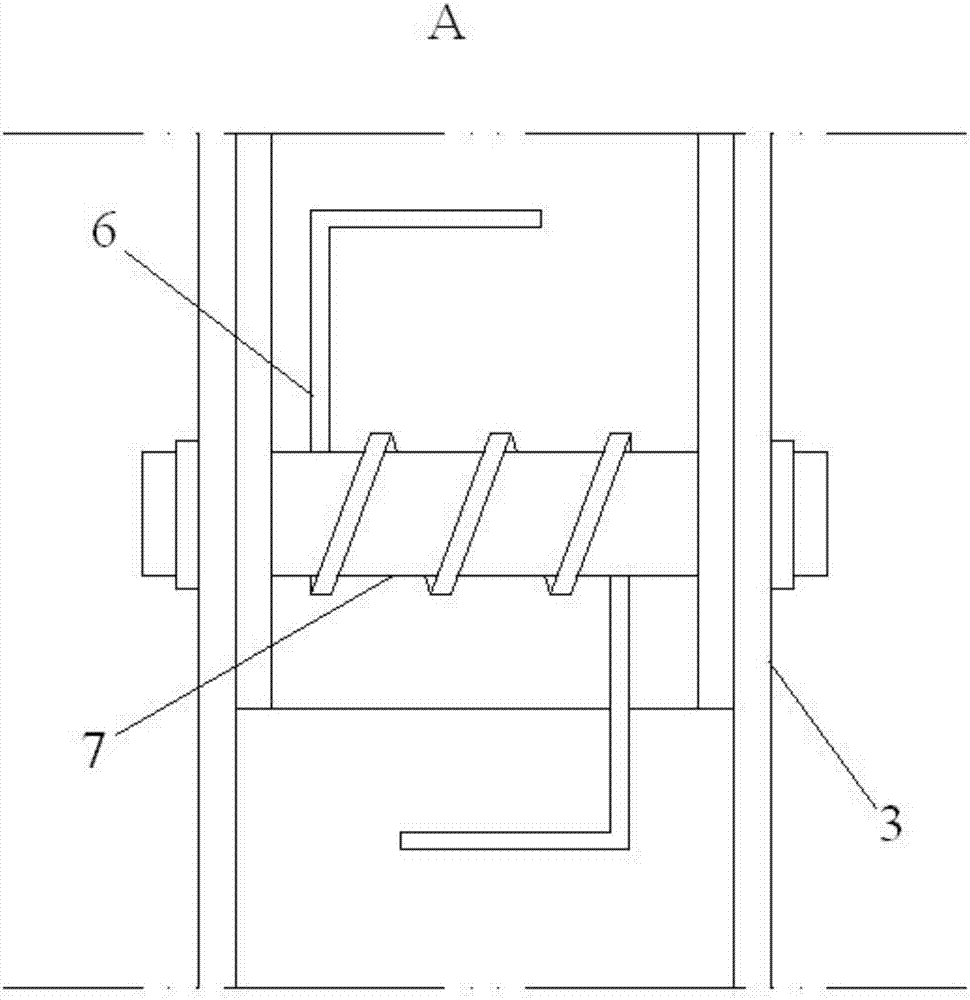

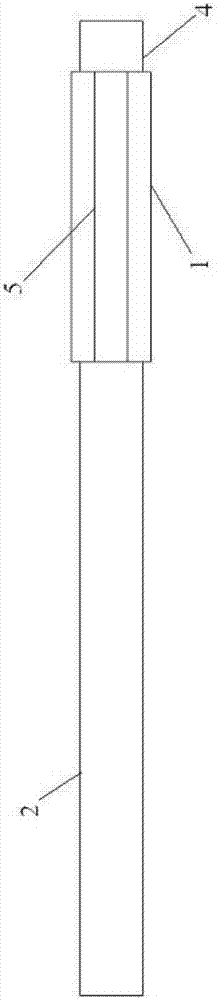

[0022] refer to figure 1 and image 3 , the embodiment of the present invention provides a kind of parallel fork pliers, comprises: two fork pliers bodies and two cross rods 3; It is the fork tong rod 2, the telescopic handle and the fork tong rod 2 are on the same straight line, one end of the telescopic handle is provided with a hinge joint, and a hinge seat is provided between the telescopic handle and the fork tong rod 2; the middle parts of the two cross rods 3 are hinged One end of the two cross bars 3 is respectively hinged with a hinge head, and the other end of the two cross bars 3 is respectively hinged with a hinge seat.

[0023] In the above embodiments, when the telescopic handle is kneaded, the two cross bars 3 rotate relatively around the first hinge shaft 7, and the distance between the hinge head and the hinge seat on each fork pliers body becomes longer, and the two fork pliers bars 2 are connected to each other. Approaching, because the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com