Method and device for preparing metal composite pipe through interface fusion method

A metal clad pipe and fusion technology is applied in the field of preparing metal clad pipes by an interface fusion method, which can solve the problems of limited length of the clad pipe, occurrence of safety accidents, easy damage, etc., so as to achieve low production cost, reduce heat loss, and ensure quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a metal composite pipe by an interface fusion method adopts the following steps:

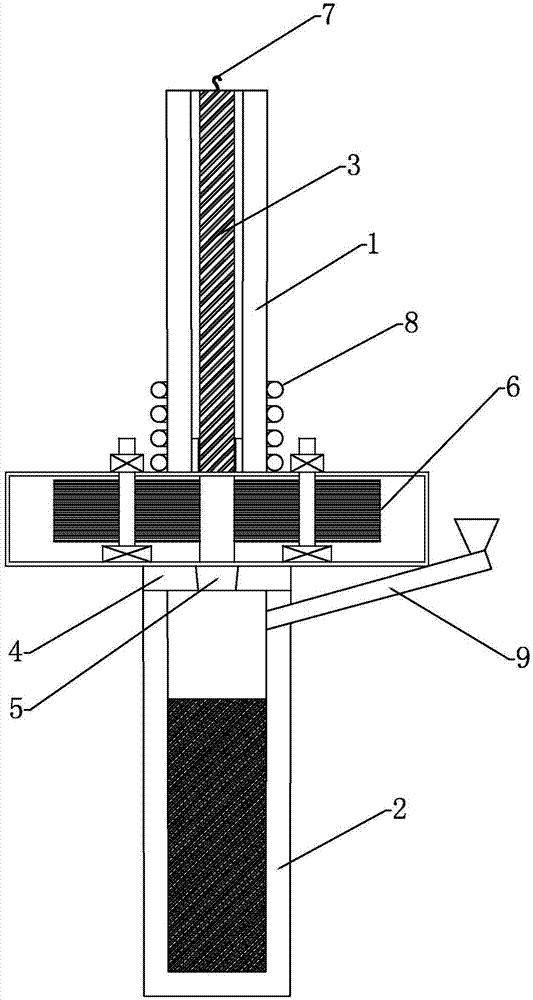

[0028] (1) Take two ceramic pipe molds, one of which is a cylindrical heating pipe mold 1 with an inner diameter and length of φ165mm*1200mm, and the other ceramic pipe mold is a pouring pipe mold 2 with a taper of 1000:1. And the length is φ169mm*1000mm, and the big head diameter of pouring pipe mold 2 is φ170.2mm, and the inner diameter of heating pipe mold 1 is 6mm larger than the rod core diameter, that is, the 20# steel pipe with a diameter of φ159mm and a wall thickness of 30mm is used as the rod core; The top opening of the pouring pipe mold 2 is covered with a ceramic plate 4, and an inverted tapered guide hole 5 is provided in the middle of the ceramic plate 4. The inner diameter of the bottom end of the guide hole 5 is 1mm larger than the diameter of the rod core, that is, φ166mm; the heating tube The axes of mold 1, pouring pipe mold 2 and guide hole 5 ar...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is that: in step (5), when the melting point of the alloy metal liquid is higher than the melting point of the rod core, the temperature of the alloy metal liquid is above the melting point of the alloy metal liquid by 30°C.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is that: in step (5), when the melting point of the alloy metal liquid is lower than the melting point of the rod core, the temperature of the alloy metal liquid is above the melting point of the rod core by 30°C.

[0050] Such as figure 1 As shown, a device for preparing metal composite pipes by interface fusion method includes a cylindrical heating pipe mold 1 and a pouring pipe mold 2 with a taper of 1000:1. The inner diameter of the heating pipe mold 1 is larger than the diameter of the rod core 3 Larger than 6mm, the thin end opening at the bottom of the pouring pipe mold 2 is closed and the diameter of the thin end opening is slightly larger than the outer diameter of the metal composite pipe; the top opening of the pouring pipe mold 2 is covered with a ceramic plate 4, and there is a An inverted tapered guide hole 5, the inner diameter of the bottom end of the guide hole 5 is 1mm larger than the diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com