A low -temperature sulfur sulfur -tolerant drooling dark catalyst

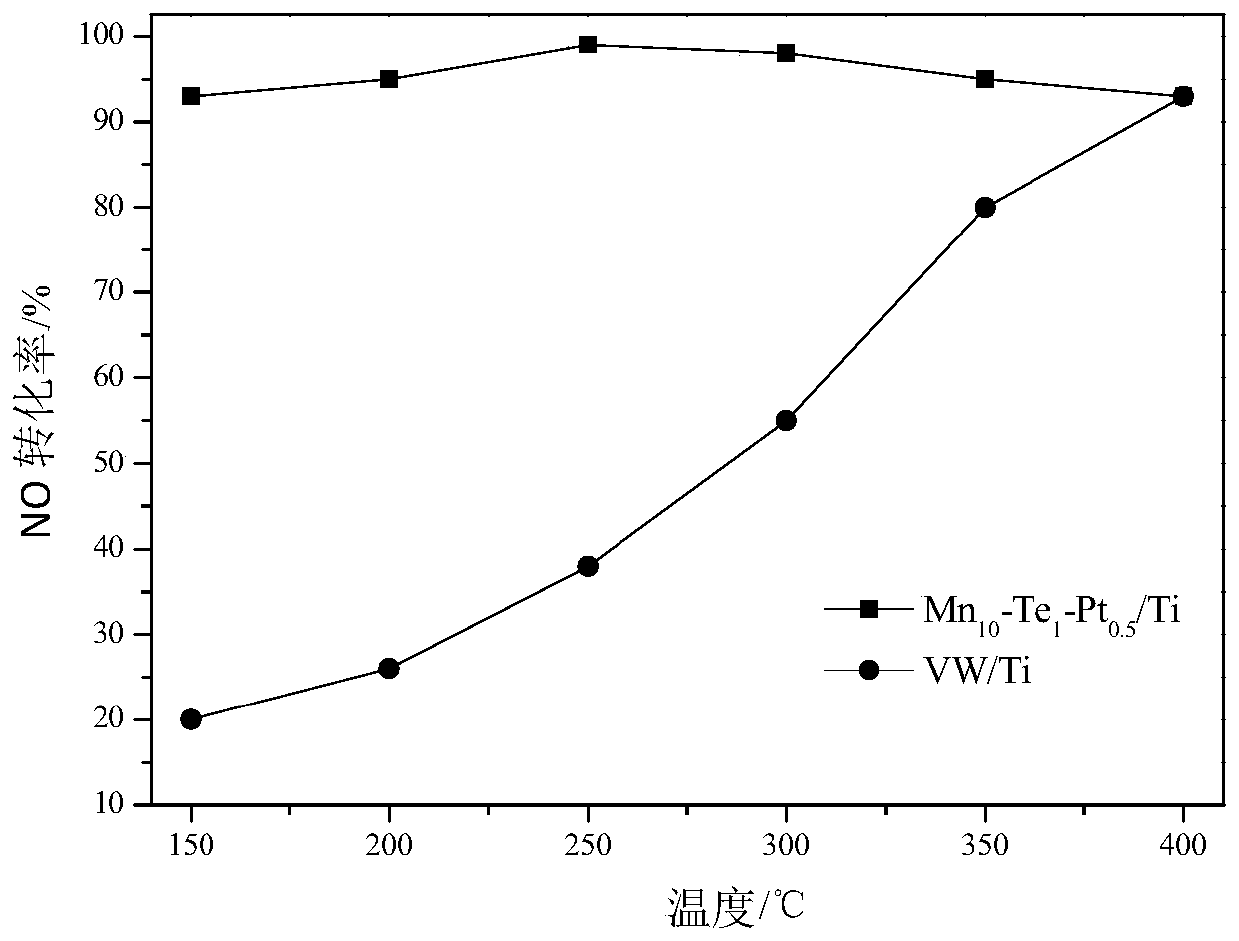

A denitrification catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low denitrification efficiency, difficult decomposition, catalyst poisoning and deactivation of vanadium-titanium catalysts, etc., to achieve The effects of low denitrification efficiency attenuation and excellent low temperature sulfur resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 10 g of the carrier, and test the saturated water absorption (solid-to-liquid ratio) of the carrier by the equal-volume impregnation method.

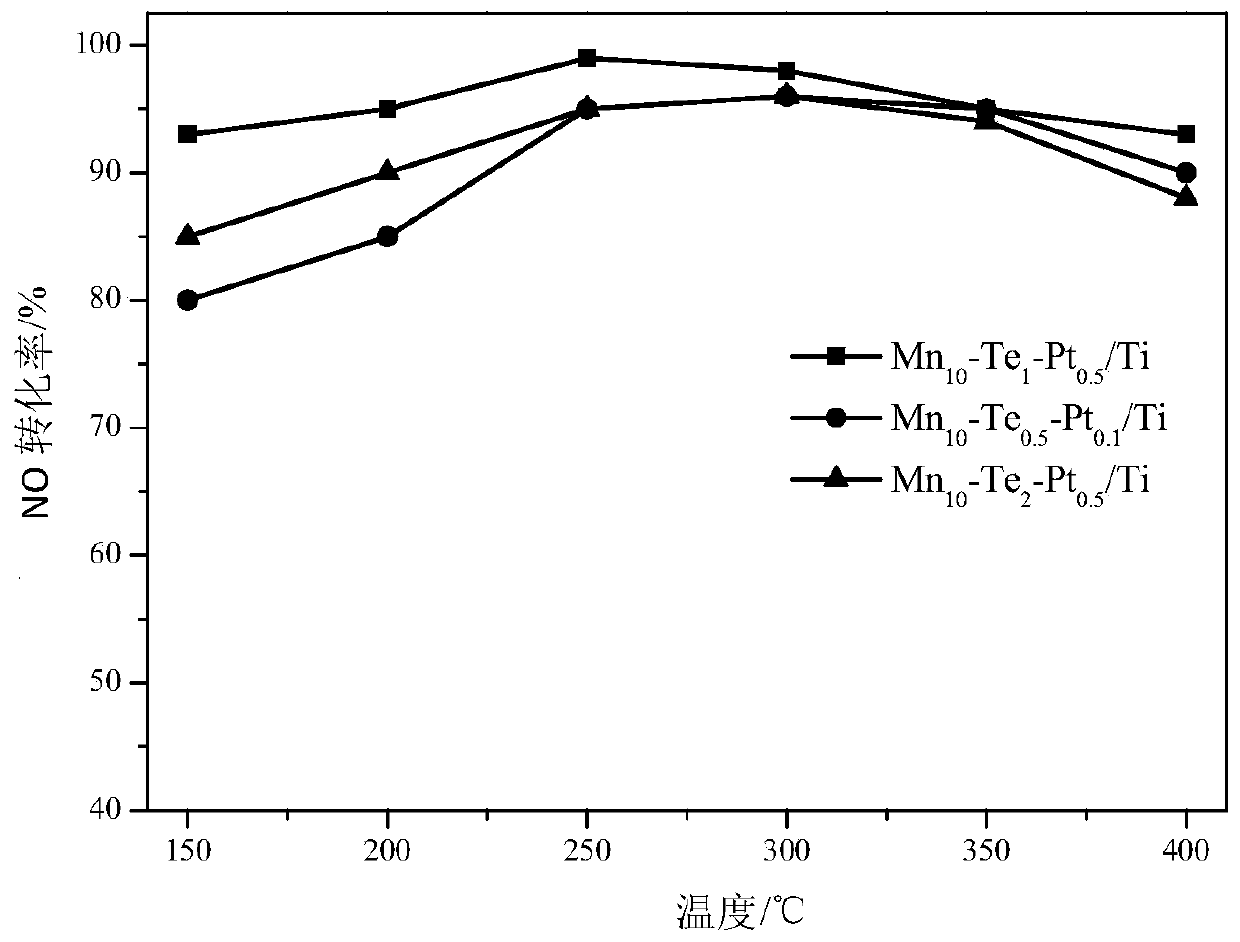

[0037] Take 10g of titanium dioxide carrier and impregnate Mn(NO 3 ) 2 ·5H 2 O and K 2 TeO 3 、H 2 PtCl 6 In the mixed aqueous solution, the masses of Mn, Te and Pt in the mixed aqueous solution are 1g, 0.05g and 0.01g respectively, impregnated at room temperature for 24h, then vacuum-dried at 60°C for 5h, then vacuum-dried at 110°C for 10h, and finally in the muffle furnace Calcined at 450°C for 3 hours in an air atmosphere to obtain a finished catalyst, denoted as Mn 10 -Te 0.5 -Pt 0.1 / Ti.

Embodiment 2

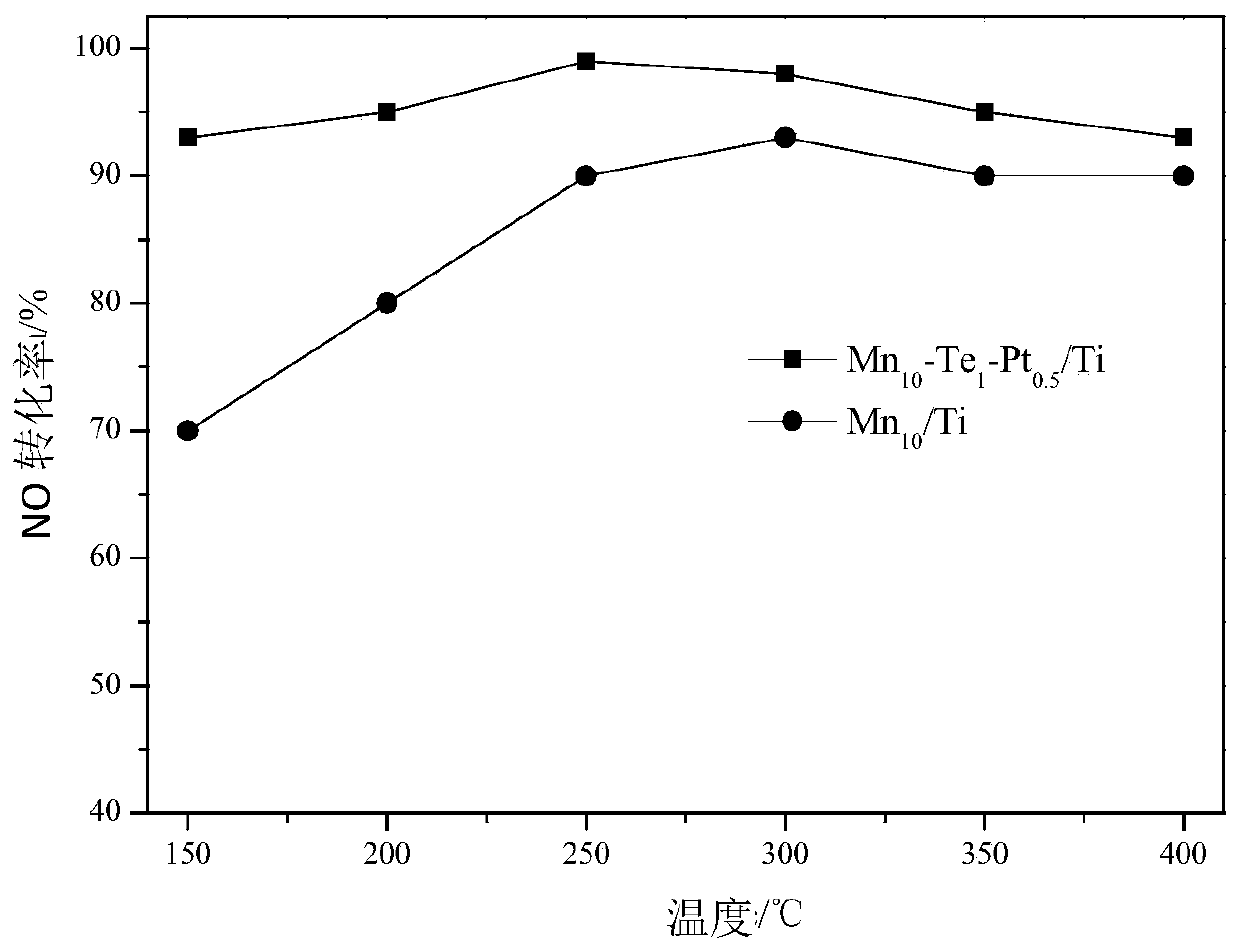

[0039] Take 10g of titanium dioxide carrier and impregnate Mn(NO 3 ) 2 ·5H 2 O and K 2 TeO 3 、H 2 PtCl 6 In the mixed aqueous solution, the masses of Mn, Te and Pt in the mixed aqueous solution are 1g, 0.1g and 0.01g respectively, impregnated at room temperature for 24h, then vacuum-dried at 60°C for 5h, then vacuum-dried at 110°C for 10h, and finally in the muffle furnace Calcined at 450°C for 3 hours in an air atmosphere to obtain a finished catalyst, denoted as Mn 10 -Te 1 -Pt 0.1 / Ti.

Embodiment 3

[0041] Take 10g of titanium dioxide carrier and impregnate Mn(NO 3 ) 2 ·5H 2 O and K 2 TeO 3 、H 2 PtCl 6 In the mixed aqueous solution, the masses of Mn, Te and Pt in the mixed aqueous solution are 1g, 0.2g and 0.05g respectively, impregnated at room temperature for 24h, then vacuum-dried at 60°C for 5h, then vacuum-dried at 110°C for 10h, and finally in the muffle furnace Calcined at 450°C for 3 hours in an air atmosphere to obtain a finished catalyst, denoted as Mn 10 -Te2 -Pt 0.5 / Ti.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com