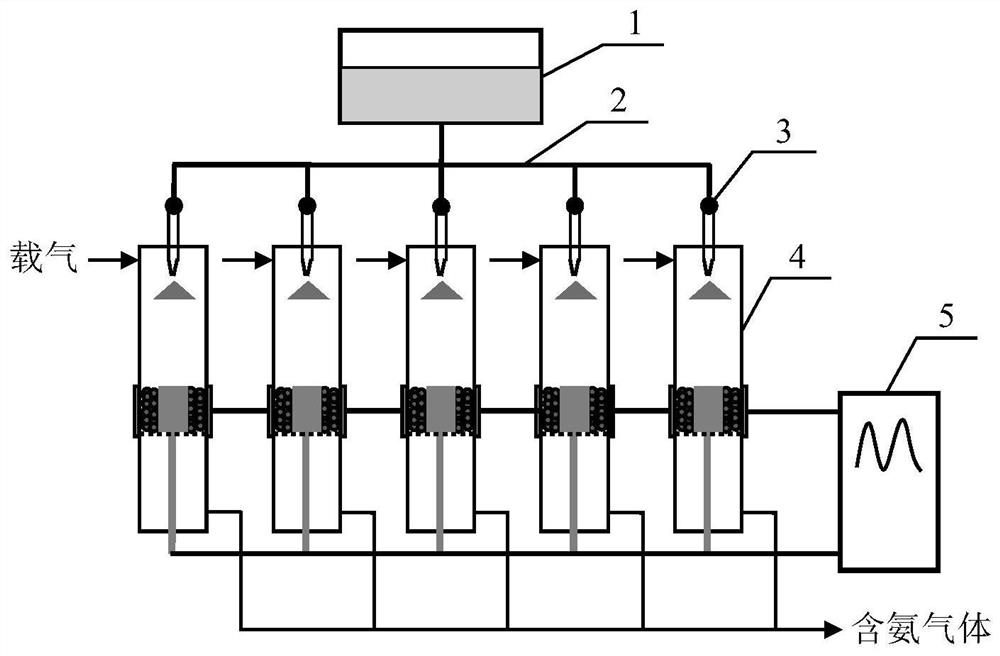

Device for preparing ammonia by hydrolyzing urea at normal temperature through non-thermal plasma synergistic catalysis

A non-thermal plasma and synergistic catalysis technology is applied in the field of devices for hydrolyzing urea to produce ammonia, which can solve the problem of high reaction temperature, and achieve the effects of low cost, convenient start and stop, and less potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

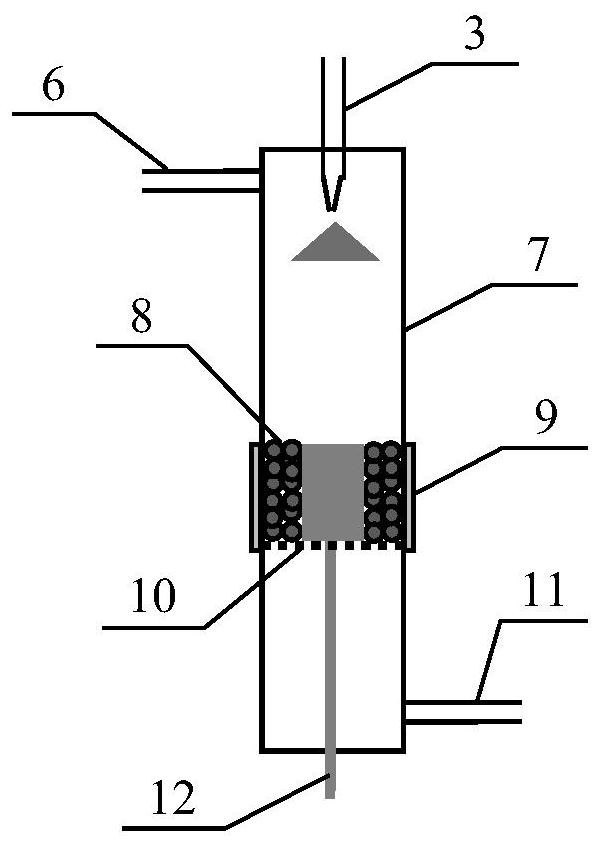

[0032] ZrO 2 As a urea decomposition catalyst, a quartz tube with an inner diameter of 7.5mm, a wall thickness of 1mm, and a length of 50cm is used as a quartz tube reactor, a stainless steel rod with a diameter of 1mm is used as a high-voltage electrode, and a 4cm-long aluminum foil is used as a grounding electrode. Take an appropriate amount of ZrO 2 Placed in the discharge area, nitrogen with a flow rate of 1L / min is passed as a carrier gas into the non-thermal plasma synergistic catalytic single-tube reactor, the concentration of urea aqueous solution is 4wt%, the injection flow rate is 16.7μL / min, and the output voltage of the AC high-voltage power supply is 22kV, frequency 200Hz, discharge power 48W, obtained NH 3 The yield was 90%.

Embodiment 2

[0034] Take Al 2 o 3 As a urea decomposition catalyst, a quartz tube with an inner diameter of 28mm, a wall thickness of 1.5mm, and a length of 40cm is used as a quartz tube reactor, a stainless steel rod with a diameter of 1.4mm is used as a high-voltage electrode, and a 5cm-long aluminum foil is used as a grounding electrode. Take appropriate amount of Al 2 o 3 Placed in the discharge area, the air with a flow rate of 1L / min is passed into the non-thermal plasma synergistic catalytic single-tube reactor as the carrier gas, the concentration of urea aqueous solution is 25wt%, the injection flow rate is 20μL / min, and the output voltage of the AC high-voltage power supply is 21kV , frequency 200Hz, discharge power 44W, obtained NH 3 The yield was 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com