A kind of preparation method of core-shell structure

A technology of shell structure and shell structure, applied in the field of core-shell structure preparation, can solve the problems of affecting cell activity, inaccurate control of core and shell size, difficulty in making multi-layer shells, etc., and achieve the effect of ensuring survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

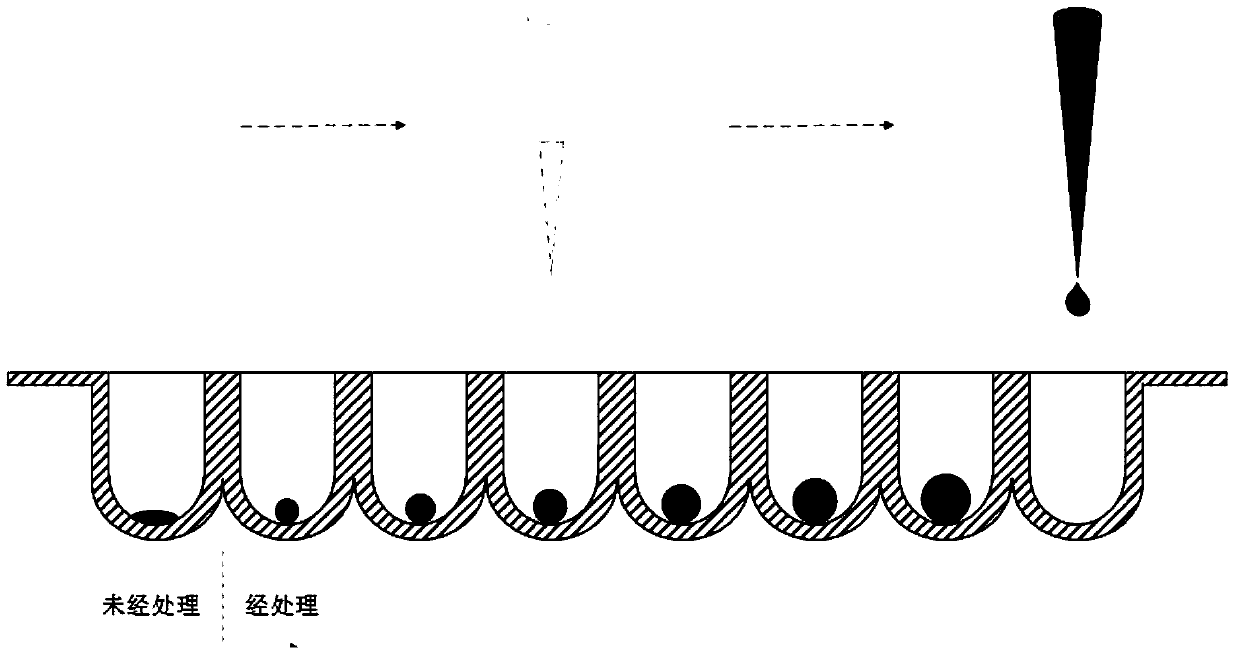

[0043] Therefore, in one aspect, the present invention provides a method for preparing a core-shell structure, comprising the following steps: a) providing a hydrophobic surface, preferably a superhydrophobic surface; b) dropping the core material solution onto the hydrophobic surface of step a), forming a droplet to obtain the innermost core layer structure; c) optionally, dropping the core material solution onto the surface of the formed droplet to obtain another core layer structure; d) optionally, dropping the wall material solution to the surface of the formed droplet to obtain a shell structure; e) optionally, repeating step c) and / or step d) one or more times or alternately performing step c) and step d) one or more times; f) Dropping the wall material solution onto the surface of the formed droplet to obtain the outermost shell structure; wherein, the choice of core material or wall material contained in each core layer or shell layer is independent.

[0044] A schemat...

specific Embodiment approach

[0137] The invention will now be described with reference to the following examples, which are intended to illustrate the invention, but not to limit it.

[0138] Reagents, kits or instruments whose sources are not specified in the examples are all conventional products commercially available on the market. Those skilled in the art understand that the examples describe the present invention by way of example and are not intended to limit the scope of the claimed invention.

Embodiment 1

[0139] The preparation of embodiment 1 superhydrophobic surface

[0140] The superhydrophobic surface used in the method of the present invention can adopt following method to prepare:

[0141] In the ultra-clean room, the U-shaped bottom orifice plate is soaked or scrubbed with alcohol and acetone to clean and dust, and the super-hydrophobic coating is applied to the inner wall of the orifice plate by soaking, spraying, etc. to form a super-hydrophobic coating. Heat and tumble dry.

[0142] The superhydrophobic surface used in the method of the present invention can also be prepared by the following methods:

[0143] After cleaning the U-shaped orifice plate with alcohol in the ultra-clean room, place the U-shaped orifice plate in hydrogen peroxide / concentrated sulfuric acid solution (30% (v / v) H 2 o 2 :H 2 SO 4 =1:3), react at 80°C for 1 hour to carry out hydroxylation treatment. Put the hydroxylated U-shaped bottom-well plate in a solution of 1H,1H,2H,2H-perfluorodecy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com