A connection method of ultra-high voltage composite cable for smart grid

A composite cable, smart grid technology, used in power cables, power cables with shielding/conducting layers, insulated cables, etc., can solve the problems of cable conductor deformation, damage, burning, etc., to ensure the effect of bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with accompanying drawing:

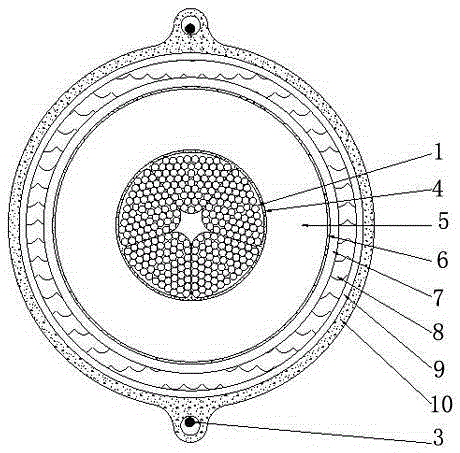

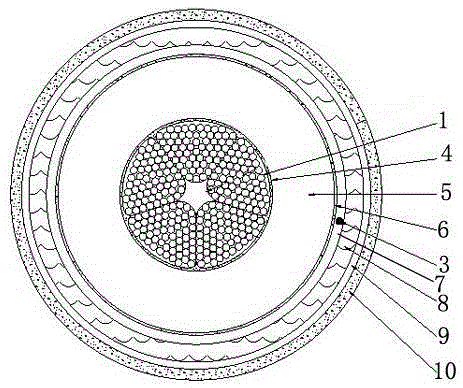

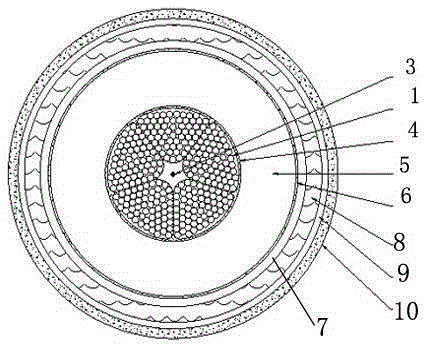

[0026] Such as Figure 4 As shown, an ultra-high voltage composite cable for a smart grid according to the present invention includes a cable conductor 1, a conductor shielding layer 4, an insulating layer 5, an insulating shielding layer 6, Semiconductive resistance water tape layer 7, corrugated aluminum sheath layer 8, corrosion protection layer 9 and non-metal outer sheath layer 10; said cable conductor 1 is provided with an optical fiber 3 in the middle, and also includes an optical fiber 3 arranged in said cable conductor 1 A metal supporting helical tube 2 that provides mechanical protection for the optical fiber 3 , and the optical fiber 3 is arranged in the metal supporting helical tube 2 .

[0027] Such as Figure 5 As shown, a method for connecting an ultra-high voltage composite cable for a smart grid includes the following steps:

[0028] 1) When connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com