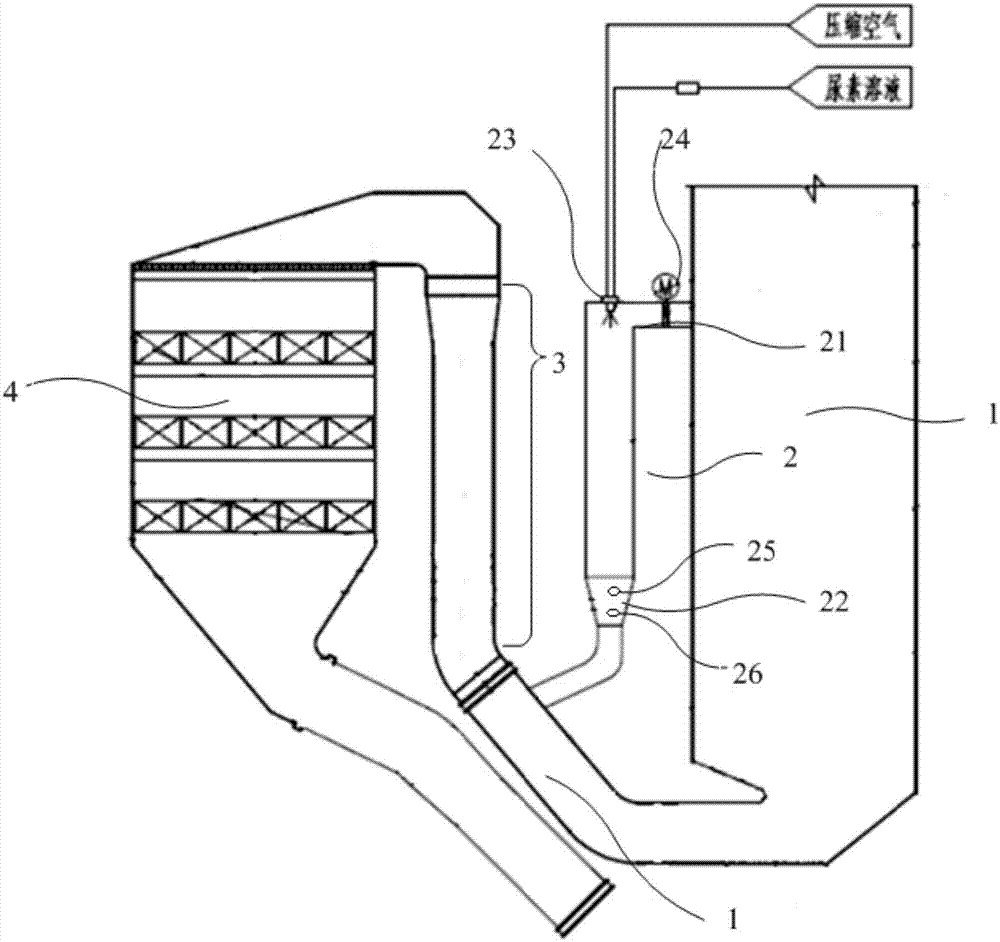

Denitration device and process for introducing high temperature flue gas for urea pyrolysis for ammonia production

A high-temperature flue gas and urea technology, applied in the field of flue gas purification, can solve the problems of incomplete decomposition of urea, blockage of air preheater, catalyst failure, etc., and achieve the effect of improving reduction reaction effect, preventing urea corrosion and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

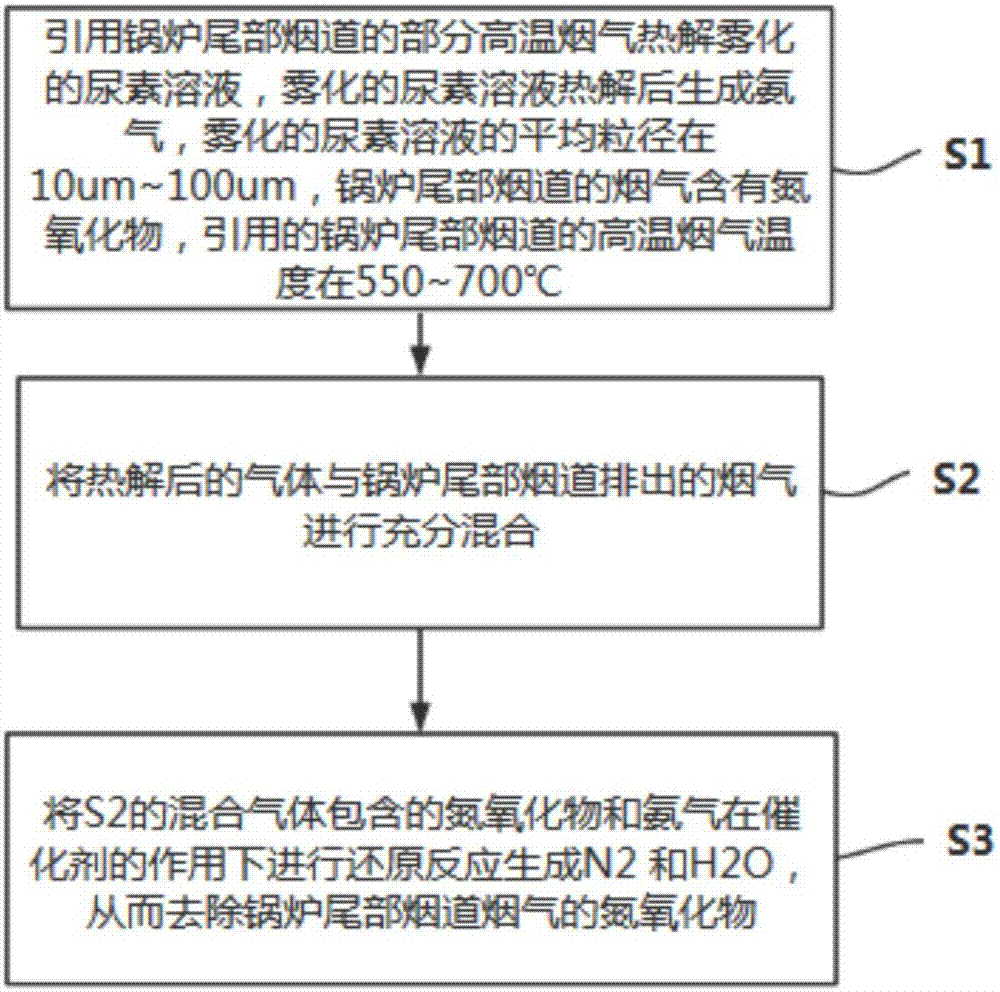

[0032] S1. Citing part of the high-temperature flue gas at the tail flue 1 of the boiler to pyrolyze the atomized urea solution, the atomized urea solution is pyrolyzed to generate ammonia gas, the average particle size of the atomized urea solution is 10um, and the mass concentration of the urea solution is 5%, the flue gas in the boiler tail flue 1 contains nitrogen oxides, the temperature of the quoted high-temperature flue gas in the boiler tail flue 1 is 550°C, and the quoted total amount of high-temperature flue gas used to pyrolyze and atomize the urea solution Accounting for 1% of the total amount of flue gas in the boiler tail flue 1;

[0033] S2, fully mixing the pyrolyzed gas with the flue gas discharged from the boiler tail flue 1;

[0034] S3, reducing nitrogen oxides and ammonia contained in the mixed gas of S2 under the action of a catalyst to generate N2 and H2O, thereby removing nitrogen oxides in the flue gas of the boiler tail flue 1.

Embodiment 2

[0036] S1. Citing part of the high-temperature flue gas at the tail flue 1 of the boiler to pyrolyze the atomized urea solution, the atomized urea solution is pyrolyzed to generate ammonia gas, the average particle size of the atomized urea solution is 50um, and the mass concentration of the urea solution is 28%, the flue gas in the boiler tail flue 1 contains nitrogen oxides, the quoted temperature of the high-temperature flue gas in the boiler tail flue 1 is 620°C, and the quoted total amount of high-temperature flue gas used to pyrolyze and atomize the urea solution Accounting for 5% of the total amount of flue gas in the boiler tail flue 1;

[0037] S2, fully mixing the pyrolyzed gas with the flue gas discharged from the boiler tail flue 1;

[0038] S3, reducing nitrogen oxides and ammonia contained in the mixed gas of S2 under the action of a catalyst to generate N2 and H2O, thereby removing nitrogen oxides in the flue gas of the boiler tail flue 1.

Embodiment 3

[0040] S1. Citing part of the high-temperature flue gas from boiler tail flue 1 to pyrolyze the atomized urea solution, the atomized urea solution is pyrolyzed to generate ammonia gas, the average particle size of the atomized urea solution is 100um, and the mass concentration of the urea solution is The flue gas at the tail flue of the boiler contains nitrogen oxides. The temperature of the high-temperature flue gas at the tail flue of the quoted boiler is 700°C. 10% of the total amount of flue gas in the tail flue;

[0041] S2, fully mixing the pyrolyzed gas with the flue gas discharged from the boiler tail flue 1;

[0042] S3, reducing nitrogen oxides and ammonia contained in the mixed gas of S2 under the action of a catalyst to generate N2 and H2O, thereby removing nitrogen oxides in the flue gas of the boiler tail flue 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com