Chitosan-nano laponite composite gel wound dressing and preparation method thereof

A composite gel and wound dressing technology, which is applied in the fields of medical formula, medical science, drug delivery, etc., can solve the problems of wound blackening, limit the popularization and use of nano-silver dressing, and not suitable for long-term use, so as to reduce pain, promote growth and Crawling of epithelial cells, beneficial effect on dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

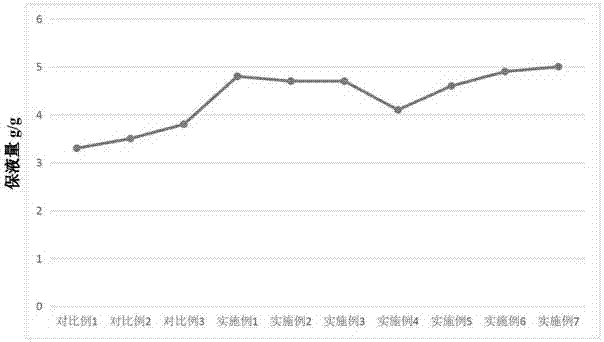

Examples

Embodiment 1

[0022] A kind of chitosan-nanometer lithium composite gel wound dressing, comprising the following raw materials in parts by weight: 3 parts of chitosan, 10 parts of nano lithium, 0.5 parts of sodium pyrophosphate, 1.5 parts of plasticizer, 15 parts of moisturizing agent, 80 parts of water.

[0023] The plasticizer is a mixture of sodium carboxymethylcellulose and hyaluronic acid with a mass fraction ratio of 3:3.

[0024] The humectant is glycerin.

[0025] The preparation method of this wound dressing comprises the steps:

[0026] 1) Take various raw materials in proportion;

[0027] 2) Take part of the water and add acetic acid to prepare an aqueous solution of acetic acid with a concentration of 1%. Dissolve chitosan in the aqueous solution of acetic acid, add a plasticizer and a humectant, and stir for 5 minutes at a temperature of 15° C. and a rotation speed of 200 rpm to obtain chitosan Sugar solution, the degree of deacetylation of chitosan is above 95%;

[0028] 3...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is only: the preparation method of this wound dressing comprises the following steps:

[0032] 1) Take various raw materials in proportion;

[0033]2) Take part of the water and add acetic acid to prepare an aqueous solution of acetic acid with a concentration of 2%. Dissolve chitosan in the aqueous solution of acetic acid, add a plasticizer and a humectant, and stir for 2 minutes at a temperature of 10° C. and a rotation speed of 150 rpm to obtain chitosan Sugar solution, the degree of deacetylation of chitosan is above 95%;

[0034] 3) Add nano-lithium celite to the remaining water to prepare a 10% nano-lithium lithium aqueous solution, then add sodium pyrophosphate at a temperature of 15° C., and stir for 15 minutes at a speed of 180 rpm, then mix with the chitosan solution in step 2) , to obtain a homogeneous composite gel;

[0035] 4) Subpackage and sterilize the composite gel prepared in step 3).

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is only: the preparation method of this wound dressing comprises the following steps:

[0038] 1) Take various raw materials in proportion;

[0039] 2) Take part of the water and add acetic acid to prepare a 3% acetic acid aqueous solution, dissolve chitosan in the acetic acid aqueous solution, add a plasticizer and a humectant, and stir for 30 minutes at a temperature of 5 ° C and a rotational speed of 200 rpm to obtain chitosan Sugar solution, the degree of deacetylation of chitosan is above 95%;

[0040] 3) Add nano-lithium celite to the remaining water to prepare a 20% nano-lithium lithium aqueous solution, then add sodium pyrophosphate at a temperature of 25° C., and stir for 20 minutes at a speed of 160 rpm, then mix with the chitosan solution in step 2) , to obtain a homogeneous composite gel;

[0041] 4) Subpackage and sterilize the composite gel prepared in step 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com