Post-treatment package of engine exhaust and application

An exhaust post-treatment and engine technology, applied in exhaust treatment, exhaust devices, engine components, etc., to achieve large heat transfer area, improve anti-crystallization ability, and facilitate evaporation and pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

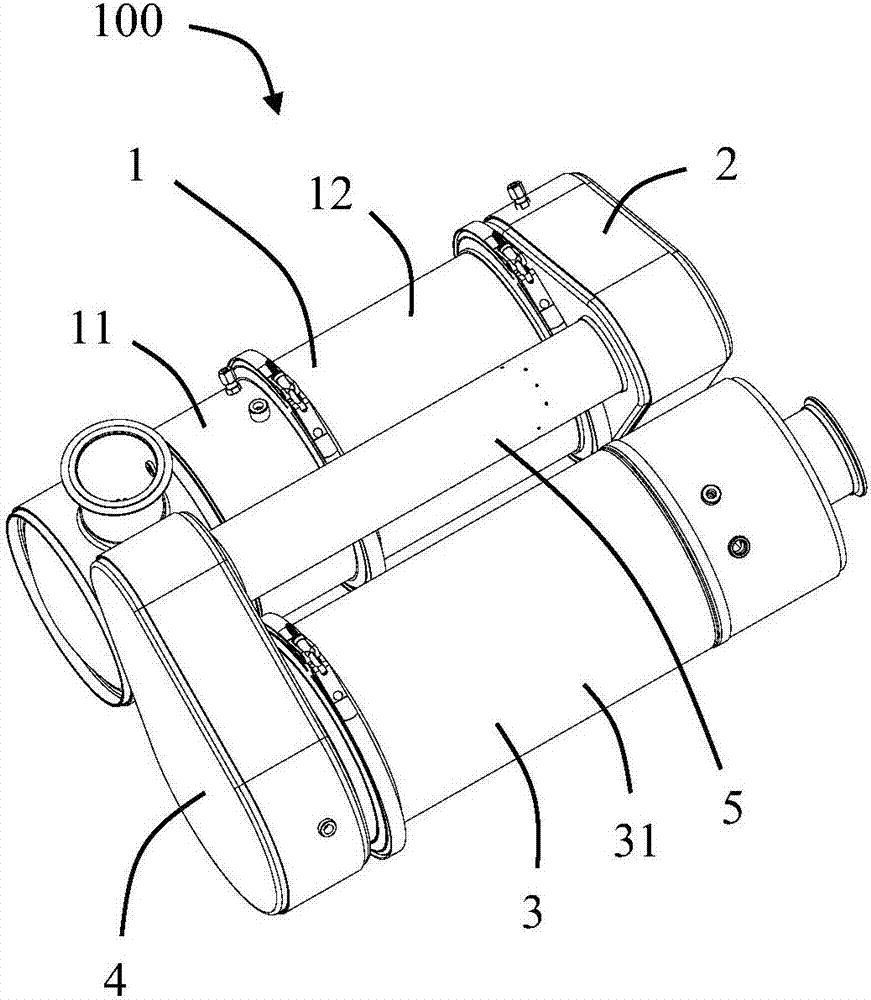

[0027] Please refer to Figure 3 to Figure 11 As shown, the present invention discloses an engine exhaust aftertreatment package 100 for use in an aftertreatment system such as an SCR to treat engine exhaust. In the illustrated embodiment of the present invention, the engine exhaust aftertreatment package 100 includes a first aftertreatment component 1, a first mixing chamber component 2 communicating with the first aftertreatment component 1, a first mixing chamber component 2 connected with the first The second after-treatment assembly 3 arranged side by side in the after-treatment assembly 1 , the second mixing chamber assembly 4 communicating with the second after-treatment assembly 3 , and the mixing tube communicating with the first and second mixing chamber assemblies 2 and 4 5. The first post-processing component 1 and the second post-processing component 3 are connected in series through the first and second mixing chamber components 2 , 4 and the mixing tube 5 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com