Rare-earth ore treatment device

A processing device and rare earth ore technology, which is applied in the field of rare earth ore processing devices, can solve problems such as no relevant reports, and achieve the effect of extending the roasting path, uniform mineral temperature, and increasing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

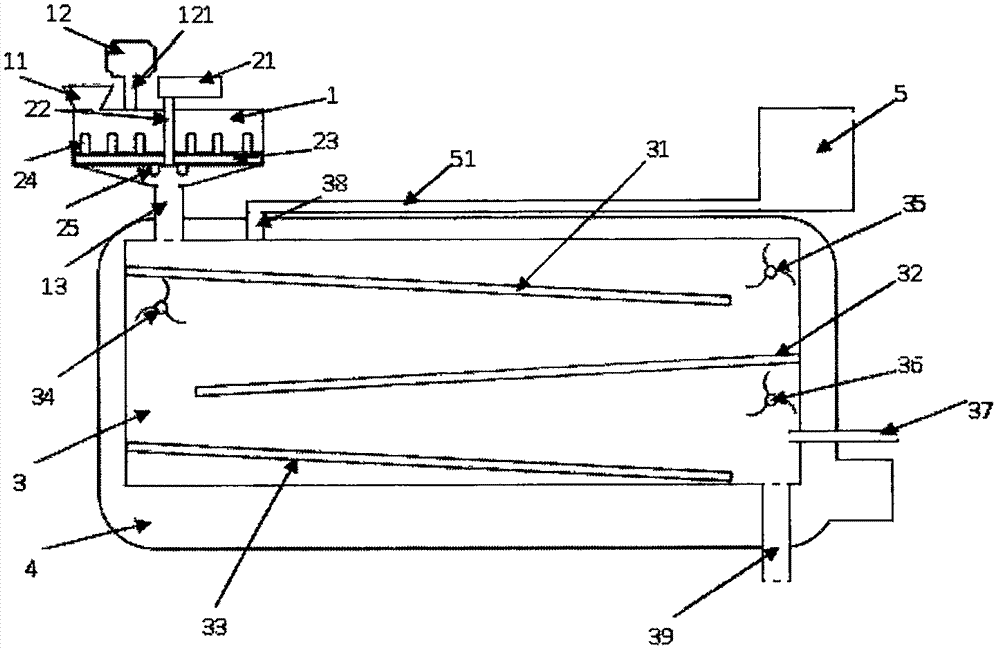

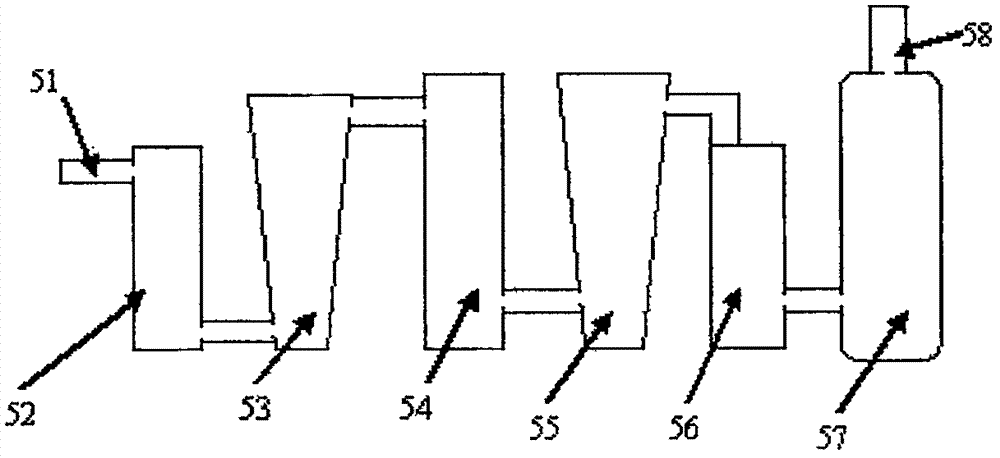

[0035] Such as figure 1 and figure 2 as shown,

[0036] A rare earth ore processing device includes a rotary hearth furnace, a slag-iron separation device, a roasting furnace and a leaching tank.

[0037] The rotary hearth furnace includes a furnace wall, a furnace roof and a rotatable annular furnace bottom. A plurality of gas burners and a plurality of secondary air nozzles are installed at intervals on the furnace wall, and an arc-shaped movable partition wall is arranged. The arc-shaped movable partition can move between the feed port and the discharge port of the rotary hearth furnace along the track of the rotary hearth furnace, and the arc-shaped movable partition is sequentially moved along the rotation direction of the annular furnace bottom. There are preheating zone, low temperature reducing zone, high temperature melting zone, soaking zone and cooling zone.

[0038] The slag-iron separation device is used for separating the rare earth slag obtained after the ro...

Embodiment 2

[0055] A rare earth ore processing device includes a rotary hearth furnace, a slag-iron separation device, a roasting furnace and a leaching tank.

[0056] The rotary hearth furnace includes a furnace wall, a furnace roof and a rotatable annular furnace bottom. A plurality of gas burners and a plurality of secondary air nozzles are installed at intervals on the furnace wall, and an arc-shaped movable partition wall is arranged. The arc-shaped movable partition can move between the feed port and the discharge port of the rotary hearth furnace along the track of the rotary hearth furnace, and the arc-shaped movable partition is sequentially moved along the rotation direction of the annular furnace bottom. There are preheating zone, low temperature reducing zone, high temperature melting zone, soaking zone and cooling zone.

[0057] The slag-iron separation device is used for separating the rare earth slag obtained after the rotary hearth furnace treatment and the pearl iron.

...

Embodiment 3

[0074] A rare earth ore processing device includes a rotary hearth furnace, a slag-iron separation device, a roasting furnace and a leaching tank.

[0075] The rotary hearth furnace includes a furnace wall, a furnace roof and a rotatable annular furnace bottom. A plurality of gas burners and a plurality of secondary air nozzles are installed at intervals on the furnace wall, and an arc-shaped movable partition wall is arranged. The arc-shaped movable partition can move between the feed port and the discharge port of the rotary hearth furnace along the track of the rotary hearth furnace, and the arc-shaped movable partition is sequentially moved along the rotation direction of the annular furnace bottom. There are preheating zone, low temperature reducing zone, high temperature melting zone, soaking zone and cooling zone.

[0076] The slag-iron separation device is used for separating rare earth slag obtained after rotary hearth furnace treatment from iron products.

[0077] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com