A stainless steel middle frame and aluminum alloy die-casting plate structure and its preparation

A technology of stainless steel and aluminum alloy, which is applied in the structure of telephone sets, sub-office equipment, electrical components, etc., can solve the problems of insufficient physical strength, no internal physical structure, and nano-hole technology can not be realized simultaneously, so as to avoid antenna problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

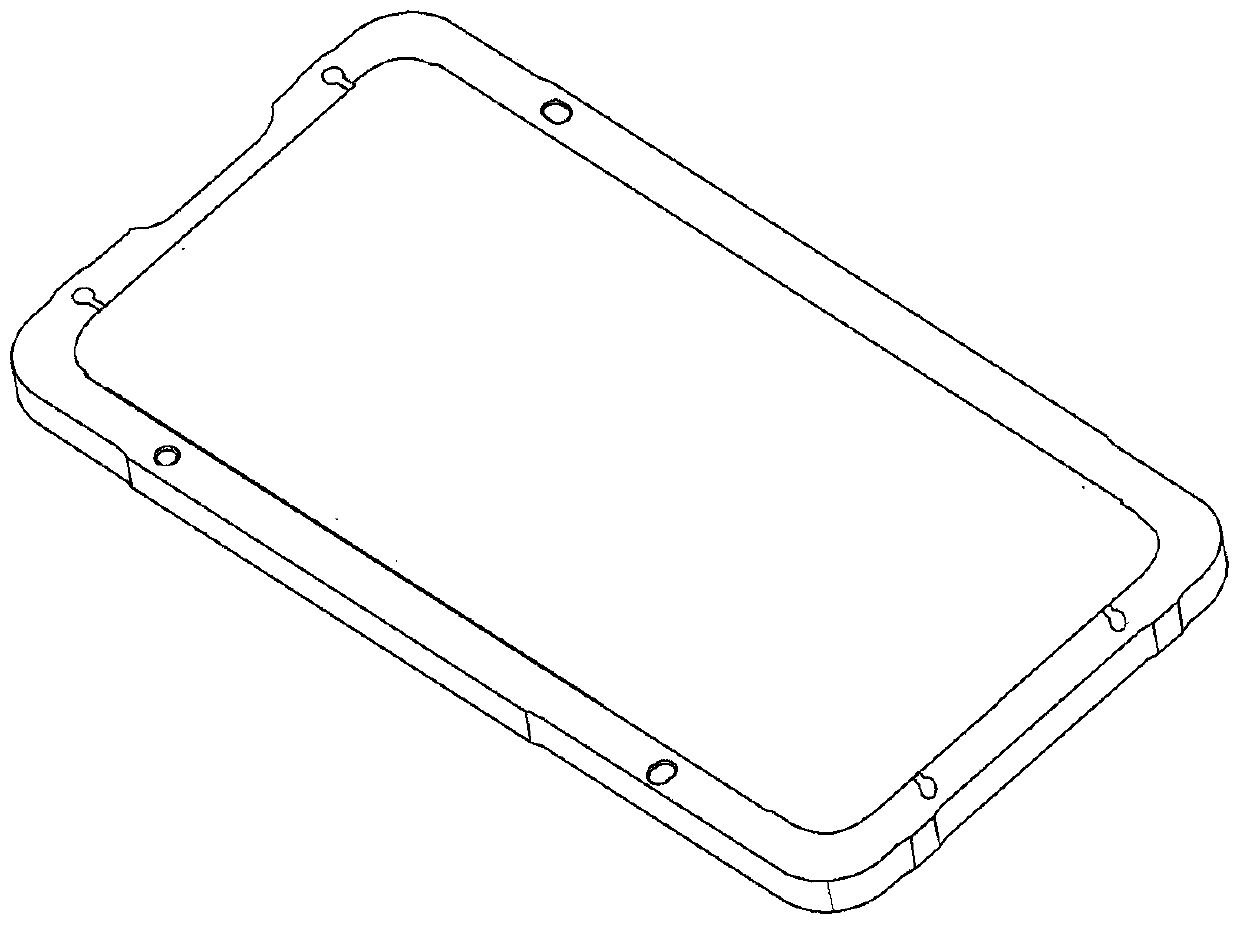

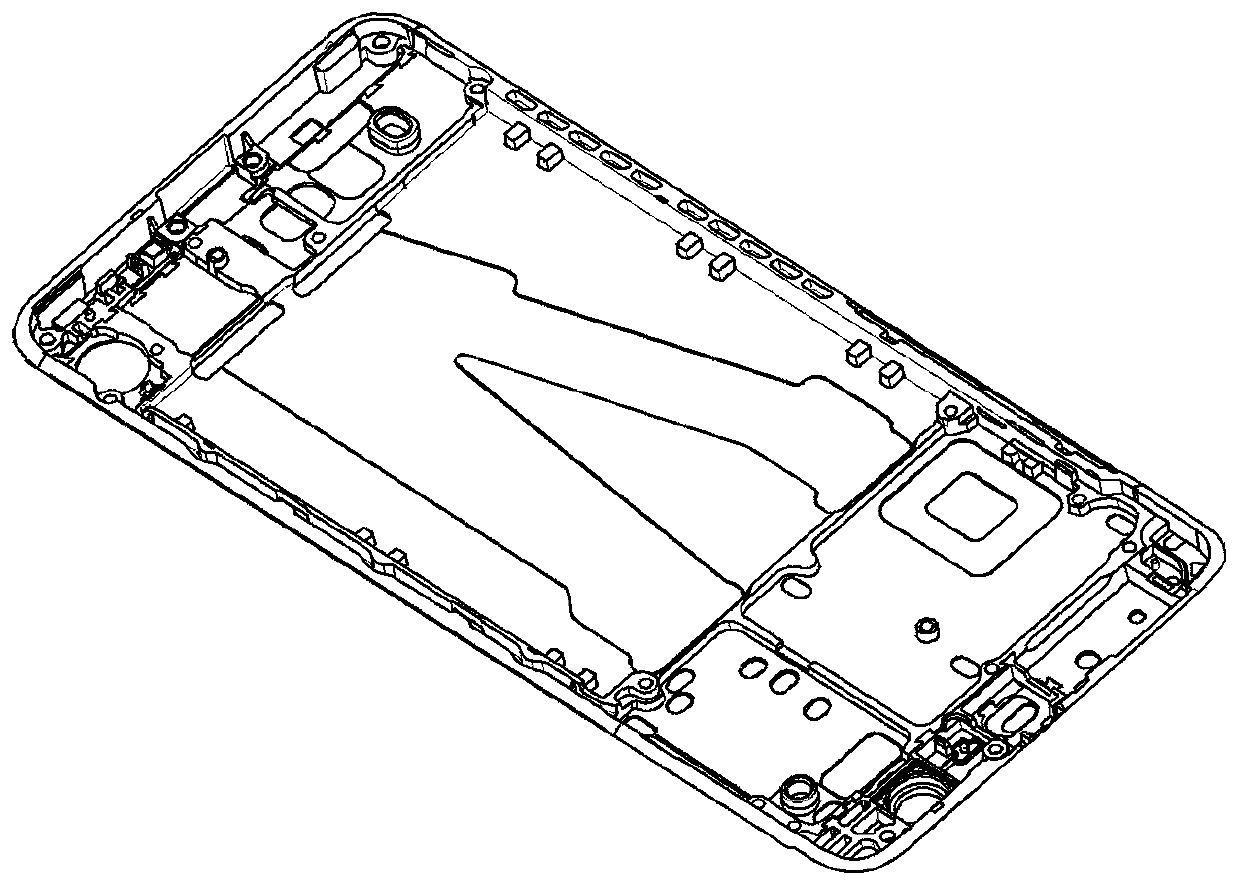

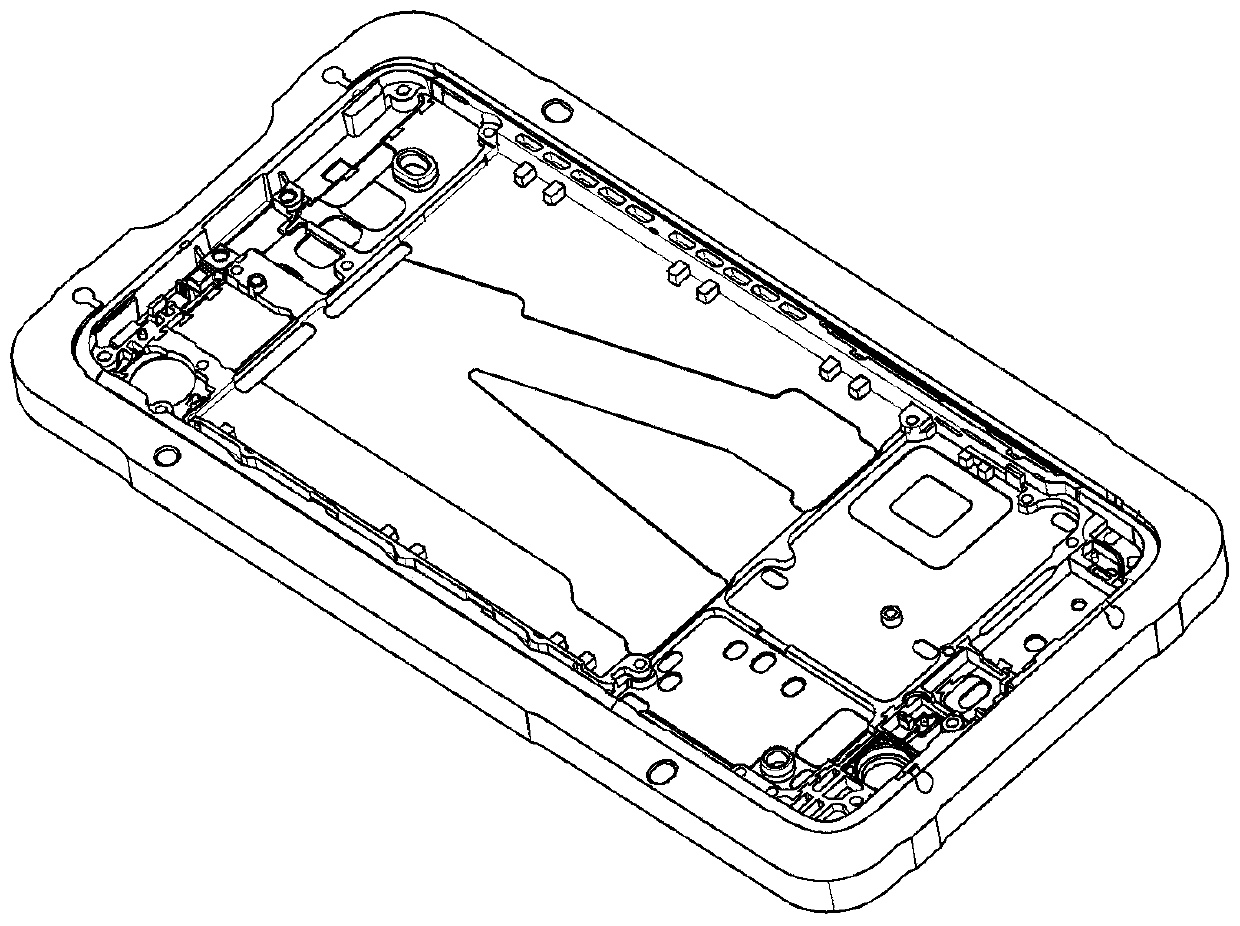

[0051] refer to Figure 1a , Figure 1b with Figure 1c , a stainless steel middle frame 1 and an aluminum alloy die-casting plate 2 structure, including a stainless steel middle frame 1 and an aluminum alloy die-casting plate 2 connected as one; the surface of the stainless steel middle frame 1 is formed with nano-holes with a diameter of 100-200nm; Nano holes with a diameter of 40-70 nm are formed on the surface of the aluminum alloy die-casting plate 2 .

Embodiment 2

[0053] The preparation method of the stainless steel middle frame and the aluminum alloy die-casting plate structure includes the following steps:

[0054] (1) The stainless steel plate is CNC-processed into a stainless steel middle frame, and the stainless steel plate is SUS304; the stainless steel middle frame is subjected to nano-electrochemical corrosion treatment, referring to Figure 1, so that nano holes with a diameter of 100-200nm are formed on the surface of the stainless steel middle frame;

[0055] (2) Aluminum alloy die-casting: select DM6 with a silicon content of 5% to 10%, and use a die-casting machine and a die-casting mold to cast and form an aluminum alloy die-casting plate; perform nano-electrochemical corrosion treatment on the aluminum alloy plate, refer to figure 2 , so that the surface of the aluminum alloy press plate forms nano-holes with a diameter of 40-70nm;

[0056] (3) The stainless steel middle frame and aluminum alloy die-casting plate obtained...

Embodiment 3

[0088] The preparation method of the stainless steel middle frame and the aluminum alloy die-casting plate structure includes the following steps:

[0089] (1) The stainless steel plate is CNC processed into a stainless steel middle frame, and the stainless steel plate is SUS316; the stainless steel middle frame is subjected to nano-electrochemical corrosion treatment, refer to figure 2 , so that the surface of the stainless steel middle frame forms nano-holes with a diameter of 100-200nm;

[0090] (2) Aluminum alloy die-casting: select ADC12 with a silicon content of 5% to 10%, and use a die-casting machine and a die-casting mold to cast and form an aluminum alloy die-casting plate; perform nano-electrochemical corrosion treatment on the aluminum alloy plate, refer to image 3 , so that the surface of the aluminum alloy plate forms nano-holes with a diameter of 40-60nm;

[0091] (3) The stainless steel middle frame and aluminum alloy die-casting plate obtained in step (1) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com