Rotary motor state monitoring method based on support vector machine and data driving

A support vector machine and rotating motor technology, applied in the direction of motor generator testing, measuring electricity, measuring electrical variables, etc., can solve problems such as inability of maintenance personnel to make different judgments, inability to save data, and increase in production costs, so as to reduce blind maintenance and sudden accident downtime, avoiding the effect of periodic scheduled downtime inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

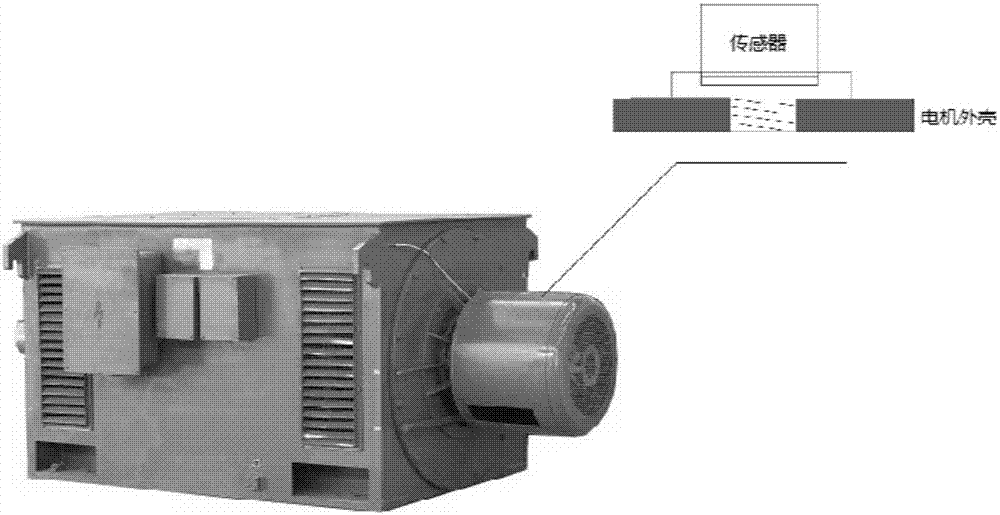

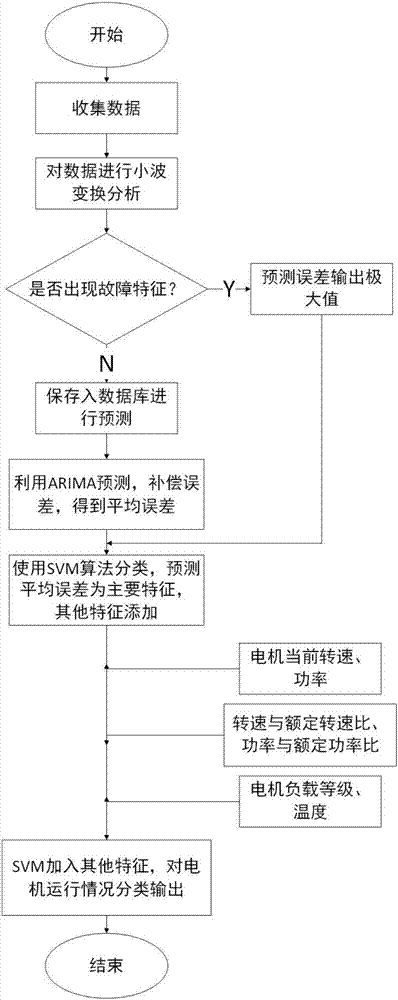

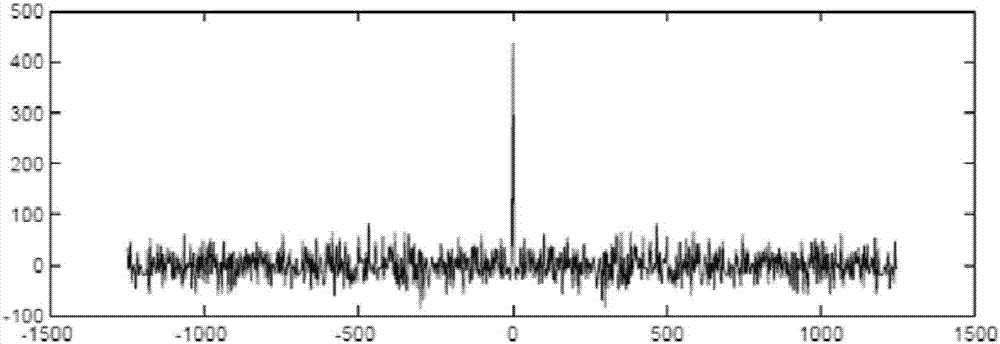

[0072] according to figure 1 , on the shell of the rotating motor, the acquisition circuit board is fixed in a threaded manner, and is fixed with three screws around it. figure 2 In order to classify the algorithm flow chart of the motor operating status, wavelet analysis, ARIMA model prediction, feature extraction and SVM classification are performed on each motor information, and the motors are divided into stable (smooth operation and low noise), good (noise), good (noise), Operation warning (failure characteristics appear in a large amount of data), operation alarm (fault characteristics are obvious and periodic, on-site inspection is recommended), operation shutdown warning (immediate shutdown, all signals are fault characteristics). Figure 3-a , Figure 3-b A spectrogram representing the sample data collected, Figure 3-a is the transformed data of the original data, Figure 3-b is the spectrogram obtained after filtering. Fig. 4 shows the root mean square curve of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com