Aluminum alloy two-step anodizing process

A secondary anodic oxidation, anodic oxidation technology, applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of reducing the anti-corrosion performance of anodized film, reducing the anti-corrosion performance of aluminum alloy, local current concentration, etc. , to achieve the effect of low production cost, simple and easy operation, and protection of aluminum alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

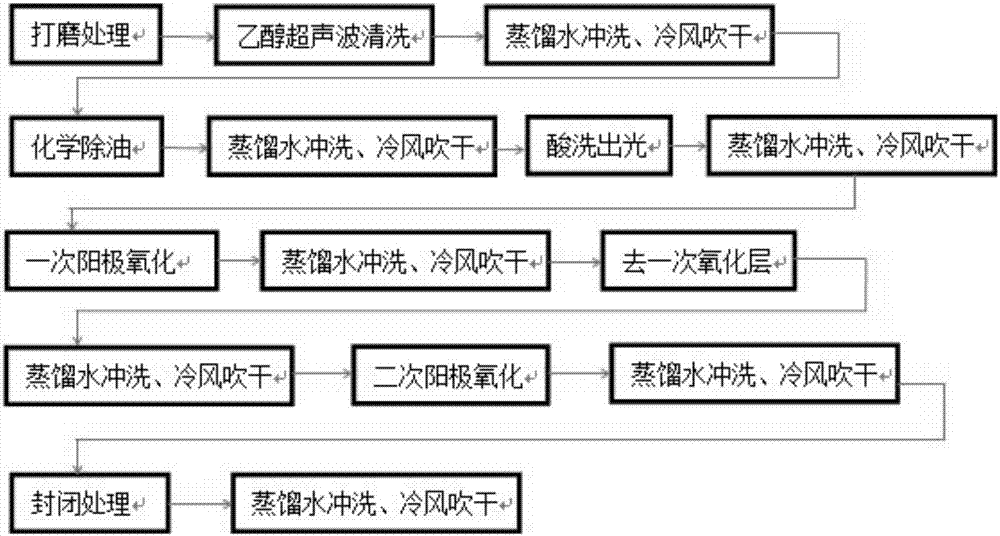

[0023] (1) Surface pretreatment of aluminum alloy styles

[0024] Grinding and cleaning: Use water sandpaper to grind from 400# to 1200# in sequence, then use ultrasonic cleaning in ethanol solution for 5 minutes, take it out, rinse it with distilled water, and dry it with cold air;

[0025] Chemical degreasing: degreasing solution: sodium hydroxide: 10g / L, coconut oil diethanolamine: 2g / L, nonylphenol polyoxyethylene ether: 0.5g / L. Use a magnetic stirrer in the degreasing solution, the speed is 60r / min, the reaction time is 2min, take it out, wash it with distilled water, and dry it with cold air;

[0026] Pickling light: pickling solution: nitric acid: 5g / L, sodium nitrate: 10g / L, sodium phytic acid: 3g / L. Use a magnetic stirrer in the pickling solution with a rotating speed of 60r / min and a reaction time of 2min, take it out, rinse it with distilled water, and dry it with cold air.

[0027] (2) The first anodizing

[0028] Use a mixed solution of 30g / L oxalic acid and 20...

Embodiment 2

[0036] (1) Surface pretreatment of aluminum alloy styles

[0037] Grinding and cleaning: Use water sandpaper to grind from 400# to 1200# in sequence, then use ultrasonic cleaning in ethanol solution for 8 minutes, take it out, rinse it with distilled water, and dry it with cold air;

[0038] Chemical degreasing: degreasing solution: sodium hydroxide: 15g / L, coconut oil diethanolamine: 4g / L, nonylphenol polyoxyethylene ether: 2g / L. Use a magnetic stirrer in the degreasing solution, the speed is 60r / min, the reaction time is 2min, take it out, wash it with distilled water, and dry it with cold air;

[0039] Pickling light: pickling solution: nitric acid: 10g / L, sodium nitrate: 7g / L, sodium phytic acid: 1g / L. Use a magnetic stirrer in the pickling solution with a rotating speed of 60r / min and a reaction time of 2min, take it out, rinse it with distilled water, and dry it with cold air.

[0040] (2) The first anodizing

[0041] Use a mixed solution of 40g / L oxalic acid and 15g / ...

Embodiment 3

[0049] (1) Surface pretreatment of aluminum alloy styles

[0050] Grinding and cleaning: Use water sandpaper to grind from 400# to 1200# in sequence, then use ultrasonic cleaning in ethanol solution for 10 minutes, take it out, rinse it with distilled water, and dry it with cold air;

[0051]Chemical degreasing: degreasing solution: sodium hydroxide: 20g / L, coconut oil diethanolamine: 8g / L, nonylphenol polyoxyethylene ether: 5g / L. Use a magnetic stirrer in the degreasing solution, the speed is 60r / min, the reaction time is 2min, take it out, wash it with distilled water, and dry it with cold air;

[0052] Pickling: pickling solution: nitric acid: 20g / L, sodium nitrate: 5g / L, sodium phytic acid: 0.1g / L. Use a magnetic stirrer in the pickling solution with a rotating speed of 60r / min and a reaction time of 2min, take it out, rinse it with distilled water, and dry it with cold air.

[0053] (2) The first anodizing

[0054] Use a mixed solution of 50g / L oxalic acid and 10g / L ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com