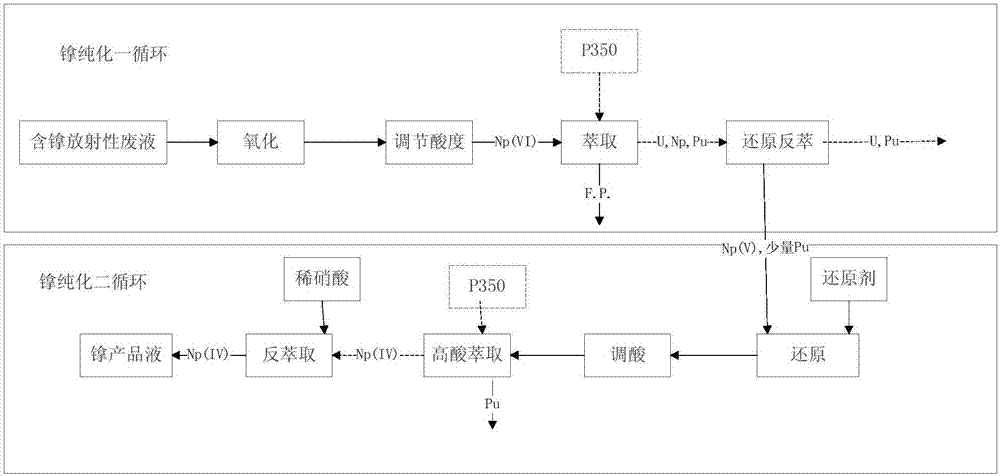

Method for extracting and recycling neptunium from spent fuel aftertreatment waste liquid

A spent fuel extraction technology, applied in the field of nuclear waste treatment and recycling, can solve only 1-2 problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Research on the Extraction Ability of P350 to Neptunium and the Reduction Ability of Reductant to Neptunium

[0034]Through research, it is found that the extraction ability of P350 to hexavalent neptunium and tetravalent neptunium is much higher than that of tributyl phosphate. Specifically, when the concentration of nitric acid in the aqueous neptunium solution is 3mol / L, and the concentration of neptunium is 0.05g / L, use 5% (v / v) P350-diluent to extract the system and 5% (v / v) TBP - The diluent extraction system extracts the aqueous phase (the ratio is 1:1, and the extraction time is 5 minutes), and after the extraction, a certain volume of the aqueous phase and the organic phase are respectively taken to measure the concentration of neptunium in them by α energy spectroscopy. The ratio of the concentration of neptunium in a certain valence state in the organic phase to the concentration of neptunium in the corresponding valence state in the aqueous phase ...

Embodiment 2

[0045] Example 2: Method for recovering neptunium from spent fuel reprocessing waste liquid through two extraction-stripping processes (1)

[0046] The experimental bench was installed in the glove box to extract and recover neptunium in the waste liquid of the spent fuel reprocessing plant.

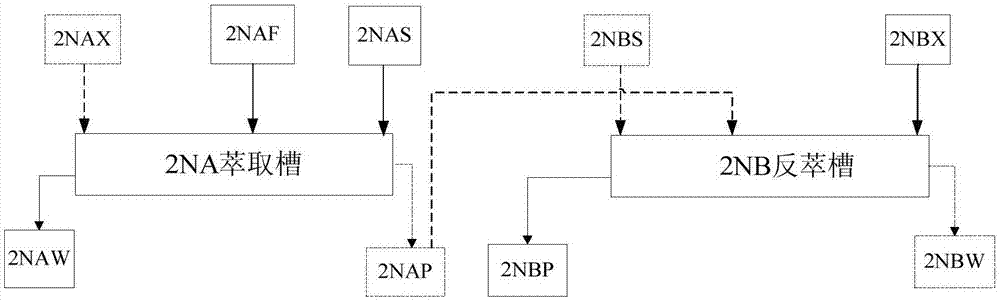

[0047] The first extraction-stripping process is as figure 2 As shown, the process steps are:

[0048] (1) After evaporating and concentrating the spent fuel reprocessing plant waste liquid, use sodium metavanadate as oxidant seasoning, 15mol / L HNO 3 Adjust the acidity to 4mol / L to obtain the feed liquid 2NAF to be purified. 2NAF contains Np, U, Pu and split elements, Np mainly exists in the form of Np(VI), and Pu mainly exists in the form of Pu(IV).

[0049] (2) 2NAF is introduced into the 2NA extraction tank, and 5% (v / v) P350-kerosene is also introduced into the 2NA extraction tank as the extraction agent 2NAX, 3mol / L HNO 3 As the detergent 2NAS, the flow ratio of 2NAF to 2NAX wa...

Embodiment 3

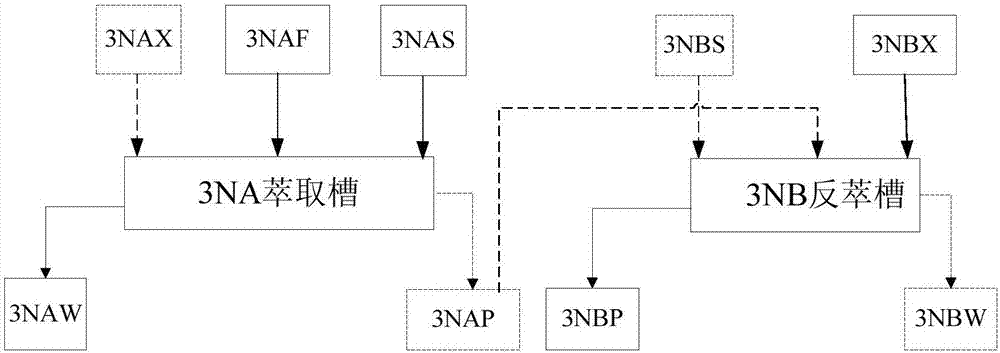

[0056] Example 3: Method for recovering neptunium from spent fuel reprocessing waste liquid through two extraction-stripping processes (2)

[0057] The first extraction-stripping process is as figure 2 As shown, the process steps are:

[0058] (1) Add reducing agent (0.1-1.0mol / LFe(NO 3 ) 2 ) to reduce Np to tetravalent and Pu to trivalent, use 5mol / L HNO 3 Adjust the concentration of nitric acid to 4mol / L to obtain the feed liquid 2NAF to be purified.

[0059] (2) 2NAF is introduced into the 2NA extraction tank, and 5% (v / v) P350-kerosene is also introduced into the 2NA extraction tank as the extraction agent 2NAX, 3mol / L HNO 3 As the detergent 2NAS, the flow ratio of 2NAF to 2NAX was 2:1. After extraction, more than 99.5% of U and Np were co-extracted into the organic phase 2NAP.

[0060] (3) Introduce the organic phase 2NAP obtained in step (2) as 2NBF into the 2NB stripping tank, and also introduce 0.1mol / LHNO in the 2NB stripping tank 3 As stripping agent 2NBX, 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com