Preparation method of cerium dioxide nanorod photocatalyst

A ceria, photocatalyst technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of troublesome preparation, reduced yield and high requirements , to achieve the effect of simple use, less energy consumption and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of ceria nanorod photocatalyst, the steps are as follows:

[0031] Preparation of type A ceria nanorod monomer

[0032] 1.5g CeCl3•7H 2 O was dissolved in 5ml deionized water to make liquid A, 2.4g NaOH was dissolved in 15ml deionized water to make liquid B, mixed liquid A and liquid B, stirred for 10min, then added the mixed solution into the reaction kettle, 130°C After reacting at low temperature for 18 hours, the obtained product was washed with deionized water, then reacted and dried at room temperature for 20 hours, and continued to be calcined at 300°C for 4 hours to obtain the A-type ceria nanorod monomer and the A-type ceria nanorod monomer Abbreviated as 3M CeO 2 .

Embodiment 2

[0034] Preparation of B-type ceria nanorod monomer

[0035] 1.5g CeCl3•7H 2O was dissolved in 5ml of deionized water to make liquid A, 4g NaOH was dissolved in 15ml of deionized water to make liquid B, mixed liquid A and liquid B, stirred for 10min, then added the mixed solution into the reaction kettle, at 130°C After reacting for 18 hours, the obtained product was washed with deionized water, then reacted and dried at room temperature for 20 hours, and continued to be calcined at 300°C for 4 hours to obtain B-type ceria nanorod monomer, which is referred to as B-type ceria nanorod monomer 5M CeO 2 .

Embodiment 3

[0037] A preparation method of ceria nanorod photocatalyst, the steps are as follows:

[0038] Preparation of C-type ceria nanorod monomer

[0039] 1.5g CeCl3•7H 2 O was dissolved in 5ml deionized water to make liquid A, 6.4g NaOH was dissolved in 15ml deionized water to make liquid B, mixed liquid A and liquid B, stirred for 10min, then added the mixed solution into the reaction kettle, 130°C After reacting at low temperature for 18 hours, the obtained product was washed with deionized water, then reacted and dried at room temperature for 20 hours, and continued to be calcined at 300 ° C for 4 hours to obtain C-type ceria nanorod monomer, C-type ceria nanorod monomer Abbreviated as 8M CeO 2 .

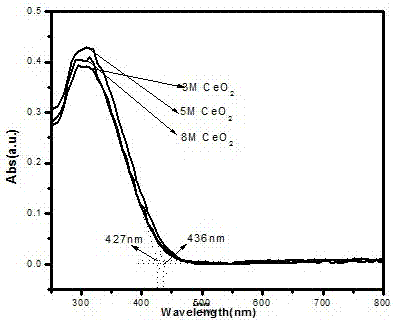

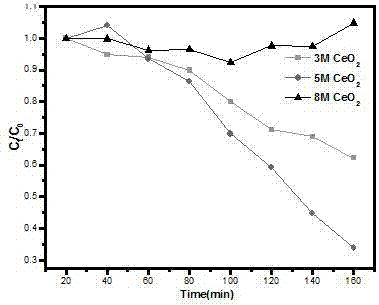

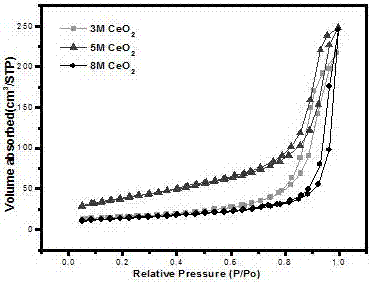

[0040] It can be seen from the accompanying drawings in the description that the light absorption capabilities of three different ceria nanorods are not the same, and 5M CeO 2 The nanorods have the strongest light absorption range, reaching 436nm (this result is obtained by making ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com