Surface modified positive electrode material and preparation method and application thereof

A cathode material and surface modification technology, applied in the field of cathode materials for lithium-ion batteries, can solve the problems of poor conductivity, inactive oxides, sacrificing partial capacity and rate performance of cathode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

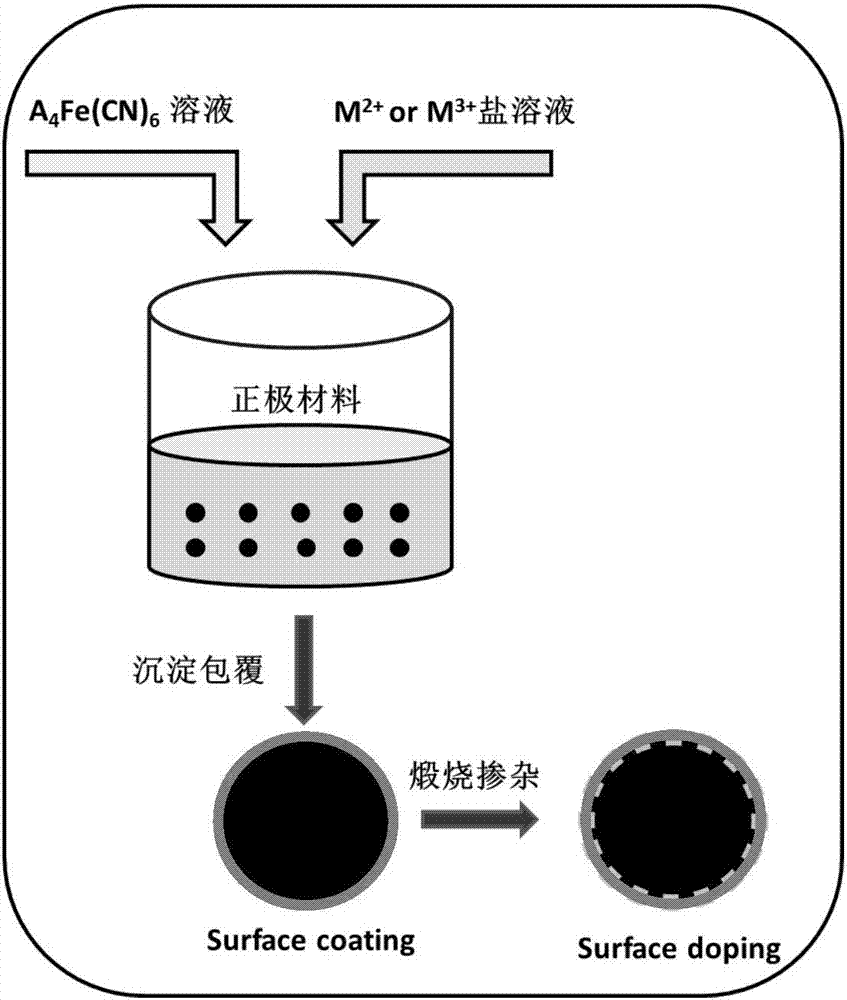

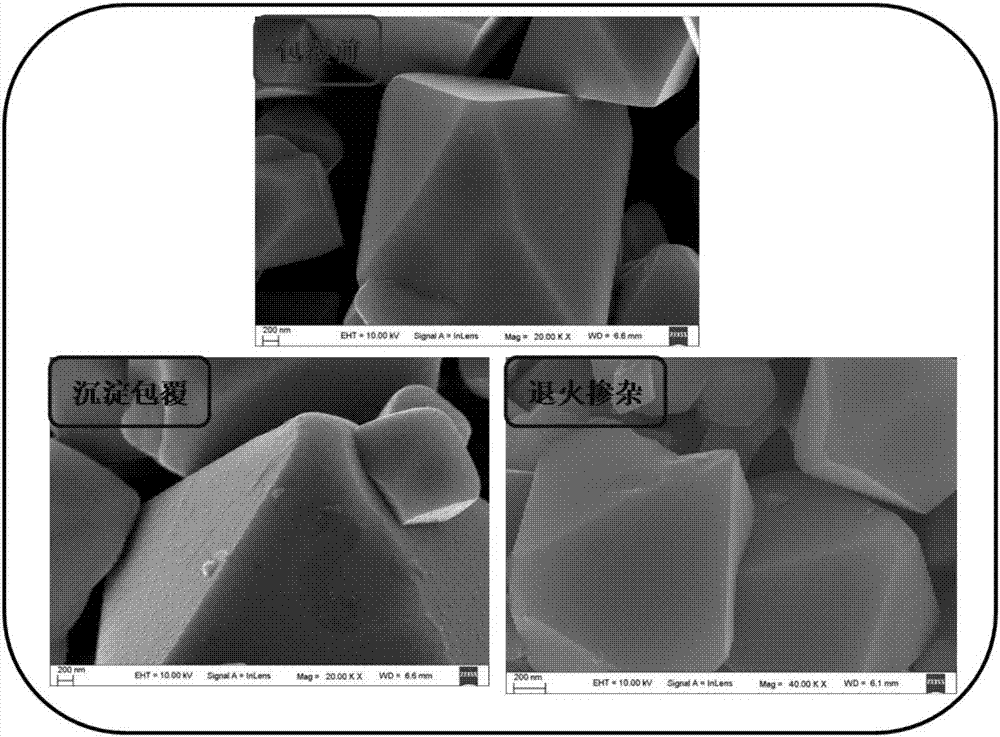

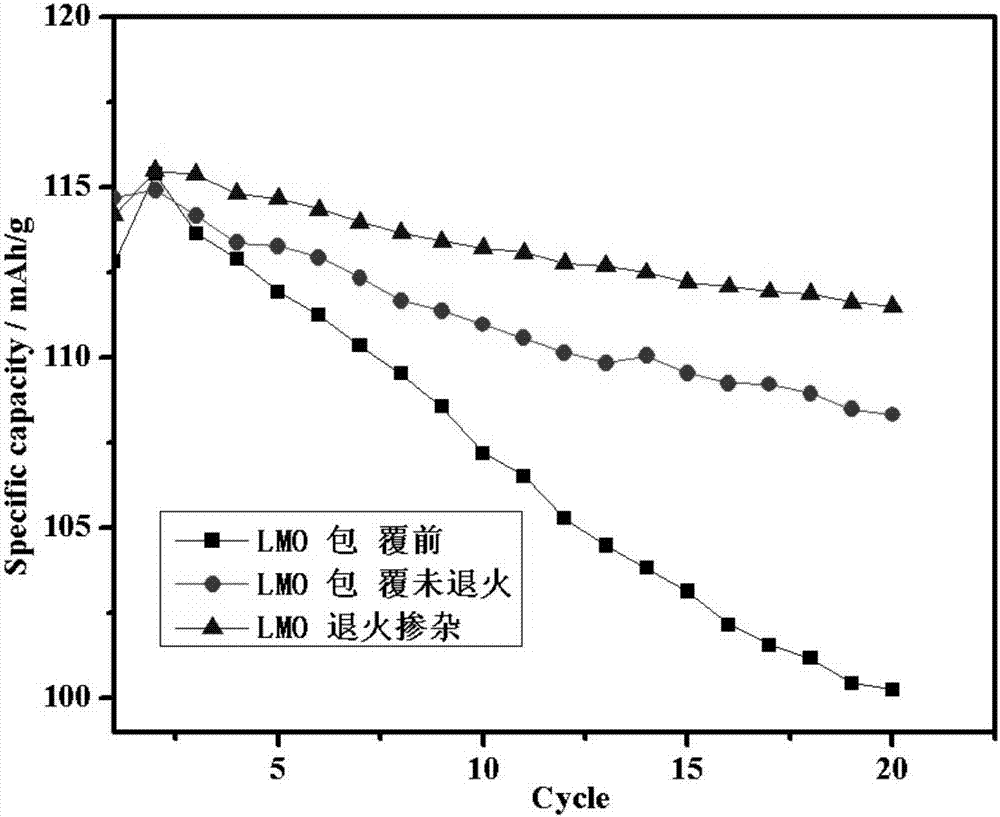

[0044] The positive electrode material in this example is Prussian blue compound K 2 NiFe(CN) 6 to LiMn 2 o 4 Coated, its preparation method is as follows figure 1 As shown, including respectively configuring alkali metal salt solution and transition metal salt solution, and then slowly adding the two to the dispersion of positive active material at the same time to obtain a positive active material physically coated with Prussian blue compounds, and then annealing treatment to obtain element-doped cathode materials.

[0045] The detailed preparation method is as follows:

[0046] Weigh 0.1689g K 4 Fe(CN) 6 and 0.1163g Ni(NO 3 ) 2 ·6H 2 O, were dissolved in 50ml of deionized water to make a solution. LiMn 2 o 4 5g of powder and 0.2g of dispersant are configured into a positive electrode active material dispersion with a mass fraction of 10%, and the positive electrode active material dispersion is placed in a water bath at 50°C. 4 Fe(CN) 6 solution and Ni(NO 3 )...

Embodiment 2

[0050] The positive electrode material in this example is Prussian blue compound Fe 4 [Fe(CN) 6 ] 3 For Li(NiCoMn) 1 / 3 o 2 The detailed preparation method is as follows:

[0051] Weigh 0.1267g K 4 Fe(CN) 6 , dissolved in 50ml of deionized water to make a solution. Another 3gLi(NiCoMn) 1 / 3 o 2 Powder, 0.0649g FeCl 3 Add 0.5g of dispersant to 100ml of deionized water to prepare a mixed dispersion containing positive electrode materials, place the mixed dispersion in a water bath at 50°C, and while stirring continuously, mix the prepared K 4 Fe(CN) 6 The solution is slowly added to the mixed dispersion liquid. After the addition is completed, the reaction is continued for 1 h, and the product is filtered, washed and dried to obtain the Li(NiCoMn) whose surface is physically coated with nano-scale Prussian blue compounds in this example. 1 / 3 o 2 . The coating amount of the Prussian blue compound detected by ICP is Li(NiCoMn) 1 / 3 o 2 2% of mass. Li(NiCoMn) whose sur...

Embodiment 3

[0053] In this example, based on Example 1, the alkali metal salt solution and the transition metal solution are respectively prepared, and then the two are slowly added dropwise into the positive electrode active material dispersion at the same time. The preparation method of this example is the same as that of Example 1, except that the specific metal salt solution, transition metal solution, and specific coated positive electrode active material are different. At the same time, the specific annealing temperature and time are also different. Other conditions And each component consumption is all identical with embodiment one. The materials and annealing treatments used in each test of this example are shown in Table 1.

[0054] Table 1 Test materials and annealing treatment

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com