Display panel with touch control function, OLED module and display

A display panel and touch function technology, applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve problems such as the inability to meet the thickness requirements of thin touch panels, so as to avoid breakage, save costs, and prevent series The effect of the color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

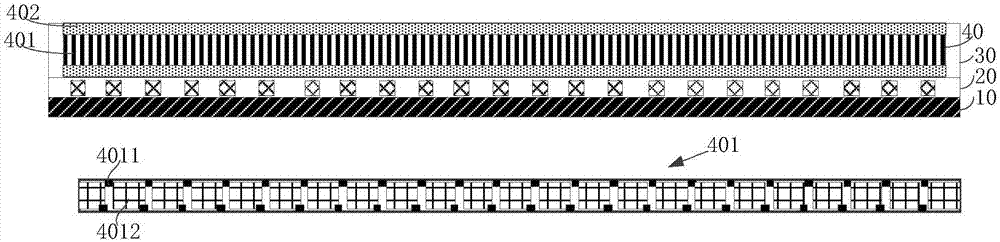

[0055] figure 1It is a structural schematic diagram of a display panel with a touch function shown according to an exemplary embodiment. The display panel includes a substrate 10 and a backplane light emitting layer 20, and the display panel also includes a film sealing layer with a touch function layer 40 30. The touch function layer 40 includes an organic film layer 401 and an inorganic encapsulation layer 402;

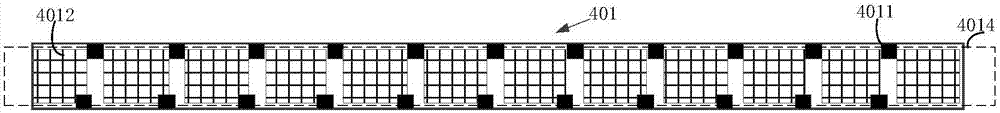

[0056] Wherein, the organic film layer 401 includes a plurality of opaque and conductive matrix blocks 4011 and a color filter (Color Filter, CF) 4012 for electrically isolating the two matrix blocks; the inorganic material encapsulation layer 402 is used to The organic film layer 401 is isolated from the outside world.

[0057] In this embodiment, the matrix blocks serve as channels for communication.

[0058] This embodiment solves the current complex process and complex film structure, simplifies the process of the process, and improves the yield of the process...

Embodiment 2

[0091] This embodiment provides an OLED module, including:

[0092] The above-mentioned display panel with touch function;

[0093] A control chip used to control the display of the display panel.

Embodiment 3

[0095] This embodiment provides a display, which includes:

[0096] The above-mentioned OLED module;

[0097] The OLED module includes:

[0098] Any one of the above-mentioned display panels with touch function;

[0099] A control chip used to control the display of the display panel.

[0100] Among them, the overall structure of the control chip is composed of a host interface, a controller, a clock generator, etc., but the internal composition of different control chips is quite different. For example, in terms of input interfaces, some control chips only have analog input interfaces; some control chips have both analog and digital interfaces; The digital signal output by the circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com