Environment-friendly vegetable oil-based emulsifying cutting fluid for machining

A vegetable oil-based, environmentally friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of complex components, high difficulty, complex molecular structure, etc., and achieve the effects of improving production efficiency, reducing costs, and large market potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

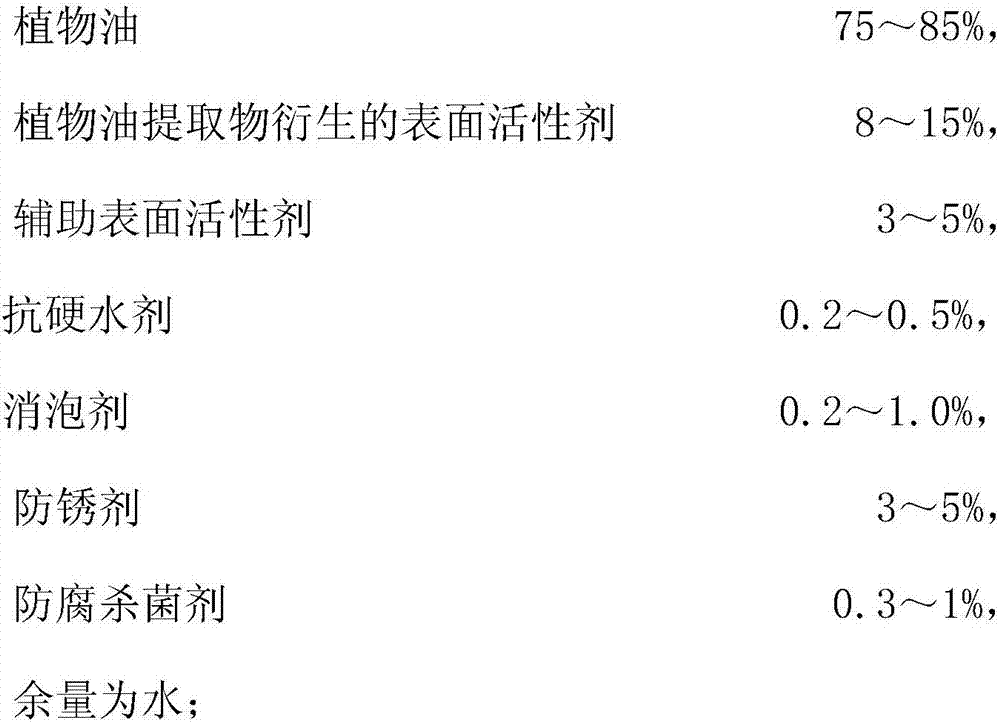

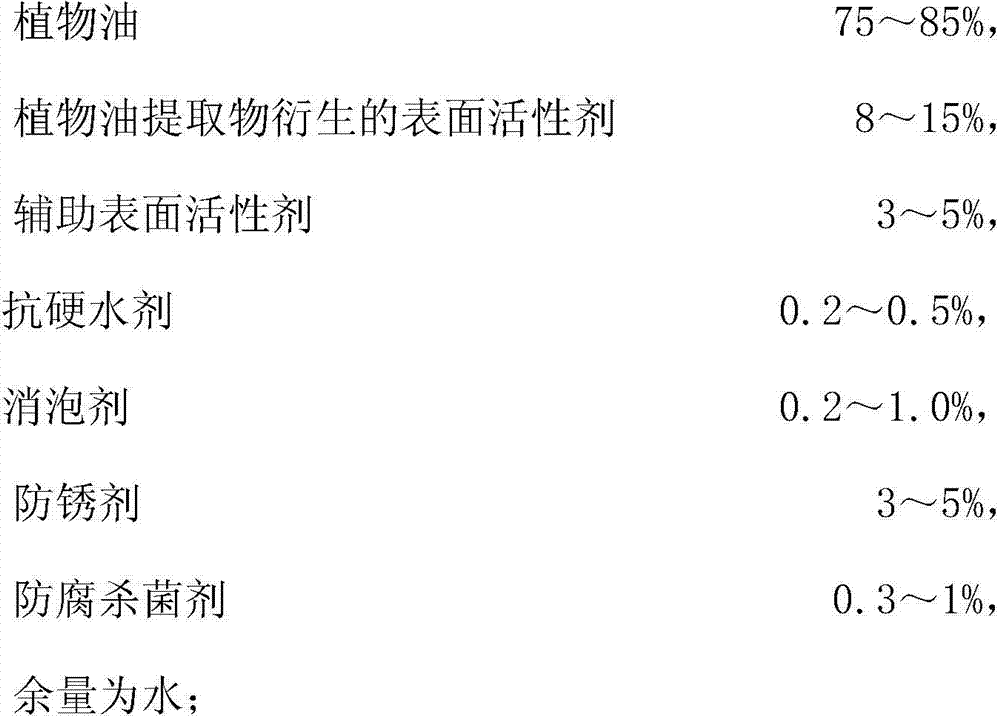

Method used

Image

Examples

Embodiment 1

[0018] An environment-friendly vegetable oil-based emulsified cutting fluid for machine tool processing, the specific preparation method of which comprises the following steps:

[0019] Take 26kg of rapeseed oil, 41kg of soybean oil, and 20kg of oleic acid and add them to the reaction vessel in sequence. 3.25kg of emulsifier, after stirring evenly, adjust the pH value to 9-9.5 with antirust agent triethanolamine, then add 0.3kg of silicone defoamer, 0.4kg of BK fungicide, and then start stirring for 30min to obtain the material liquid;

[0020] Take 1.5kg of clean water and put it into a small tool bucket, add 0.3kg of sodium ethylenediaminetetraacetate under stirring to make it completely dissolve, add dropwise to the above-mentioned material liquid under stirring, and stir evenly to obtain the sample of the present invention one.

Embodiment 2

[0022] An environment-friendly vegetable oil-based emulsified cutting fluid for machine tool processing, the specific preparation method of which comprises the following steps:

[0023] Take 80kg of soybean oil and add it to the reaction vessel. If it is heated to 25-30°C in winter, add 2kg of liquid rosin-tall oil fatty acid amide, 7kg of ricinoleic acid polyester, and NP-4 (co-surfactant) in turn under stirring. 7kg, after stirring evenly, adjust the pH value to 9-9.5 with antirust agent triethanolamine, then add 0.3kg of silicone defoamer, 0.4kg of BK fungicide, and then start stirring for 30min to obtain the material liquid;

[0024] Take 1.5kg of clean water and put it into a small tool bucket, add 0.3kg of sodium ethylenediaminetetraacetate under stirring to make it completely dissolve, then add it dropwise to the above-mentioned material liquid under stirring; stir evenly, and obtain the sample of the present invention two.

Embodiment 3

[0026] An environment-friendly vegetable oil-based emulsified cutting fluid for machine tool processing, the specific preparation method of which comprises the following steps:

[0027] Take 80kg of epoxidized soybean oil and add it to the reaction vessel. If it is preheated to 25-30°C in winter, add 3kg of liquid rosin-tall oil fatty acid amide, 6.5kg of ricinoleic acid polyester, NP-4 (auxiliary Surfactant) 8kg, after stirring evenly, adjust the pH value to 9-9.5 with antirust agent triethanolamine, then add 0.3kg of organic silicon defoamer, 0.3kg of BK fungicide, and then start stirring for 30min to obtain the material liquid;

[0028] Take 1.5kg of clean water and put it into a small tool bucket, add 0.3kg of sodium ethylenediaminetetraacetate under stirring to make it completely dissolve, then add it dropwise to the above-mentioned material liquid under stirring; stir evenly, and obtain the sample of the present invention three.

[0029] The series of samples of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com