Preparation method of Gemini emulsifier used for producing cationic rosin size

A cationic rosin gum and emulsifier technology, which is applied in the direction of rosin addition and water repellent addition, can solve the problems that the stability and emulsification ability of cationic rosin gum emulsion cannot be taken into account, the HLB value of emulsifier is single, and the stability is not good. , to achieve excellent stability, good sizing performance and fine particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

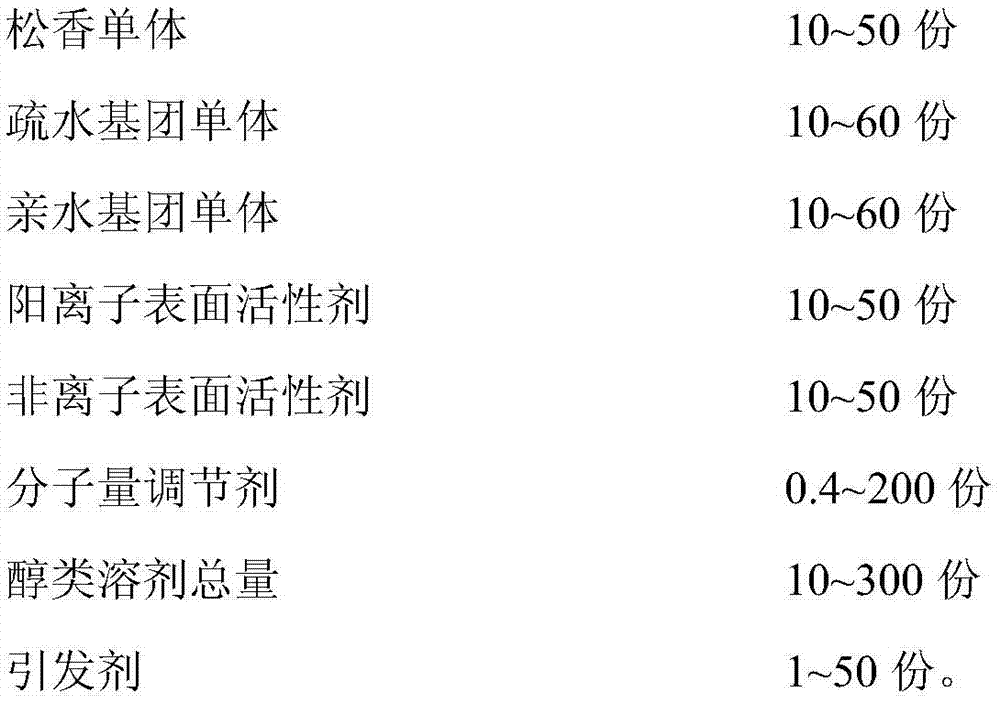

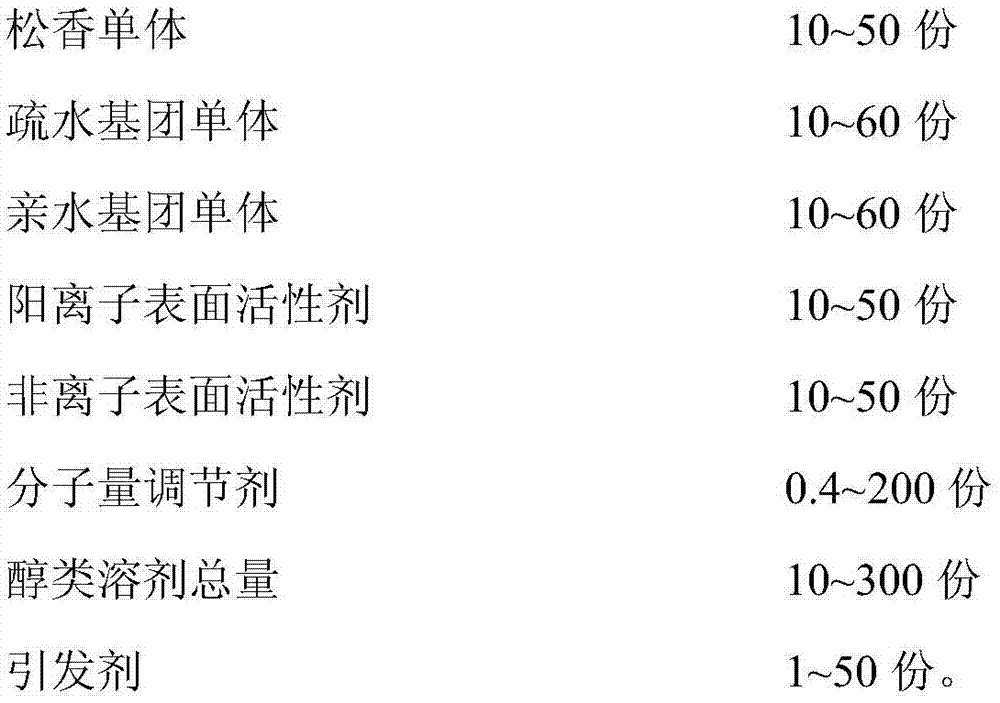

[0025] The first aspect of the present invention provides a kind of preparation method for the production of the gemini emulsifier of cationic rosin size, and described preparation method comprises the following steps:

[0026] (1) Dissolve cationic surfactant, nonionic surfactant and molecular weight regulator in a part of alcoholic solvent, mix well to obtain mixed solution I; add a part of alcoholic solvent to the reaction kettle, and then add the mixed solution I;

[0027] (2) Dissolving the rosin monomer, the hydrophobic group monomer and the hydrophilic group monomer in a part of the alcoholic solvent, and mixing uniformly to obtain a mixed solution II; and raising the temperature of the reaction kettle to 78-97°C, and Add the mixed solution II and the aqueous solution of the initiator dropwise into the reaction kettle, and keep the reaction for 3 to 5 hours;

[0028] (3) After the heat preservation reaction is complete, add distilled water to adjust the solid content t...

Embodiment 1

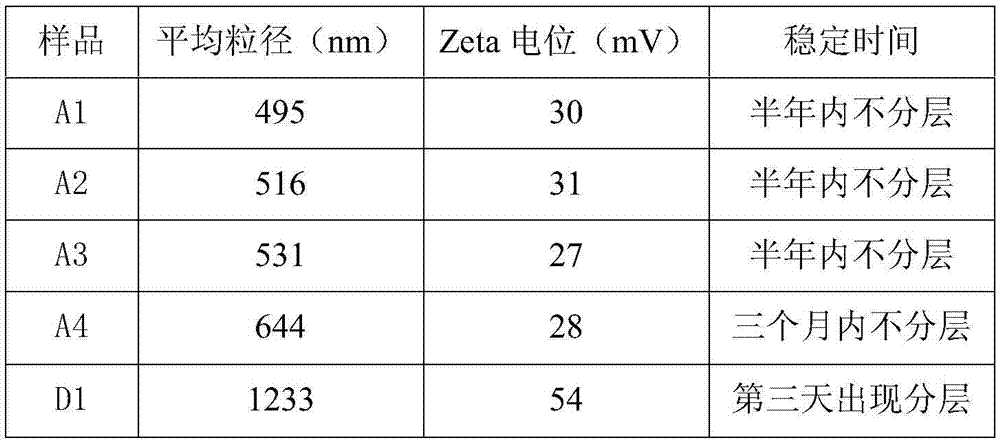

[0042] Add 50g of ethanol to the reactor, then add mixed solution I (50g of ethanol solution of 50g of dimethyl diallyl ammonium chloride, 30g of OP-10 and 8g of dodecanethiol); the reactor is heated to 78°C, Then add the mixed solution II (70g ethanol solution of 50g rosin monomer, 25g butyl acrylate, and 60g acrylamide) and an aqueous solution containing 5g ammonium persulfate dropwise at the same time, and keep warm for 4 hours; after the reaction is completed, add appropriate amount of distilled water to adjust the solid content It can be discharged after reaching 32%, and the twin emulsifier 1 is obtained.

Embodiment 2

[0044]Add 40g of isopropanol to the reaction kettle, and then add the mixed solution I (50g of diethyl diallyl ammonium chloride, 15g of AEO-9 and 6g of sodium formate in 20g of isopropanol solution); the reaction kettle is heated to 83°C , then drop the mixed solution II (40g isopropanol solution of rosin monomer 50g, styrene 10g, acrylamide 58g) and aqueous solution containing 3g sodium persulfate at the same time, keep warm for 3.5 hours; after the reaction is completed, add appropriate amount of distilled water to adjust After the solid content reaches 36%, it can be discharged to obtain Gemini emulsifier 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com