High-efficiency building timber cutting device

A cutting device and wood technology, applied in wood processing equipment, sawing equipment, manufacturing tools, etc., can solve the problems of reducing work efficiency, wasting time, and difficult to clean, so as to improve safety, prevent dust pollution, and facilitate material discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

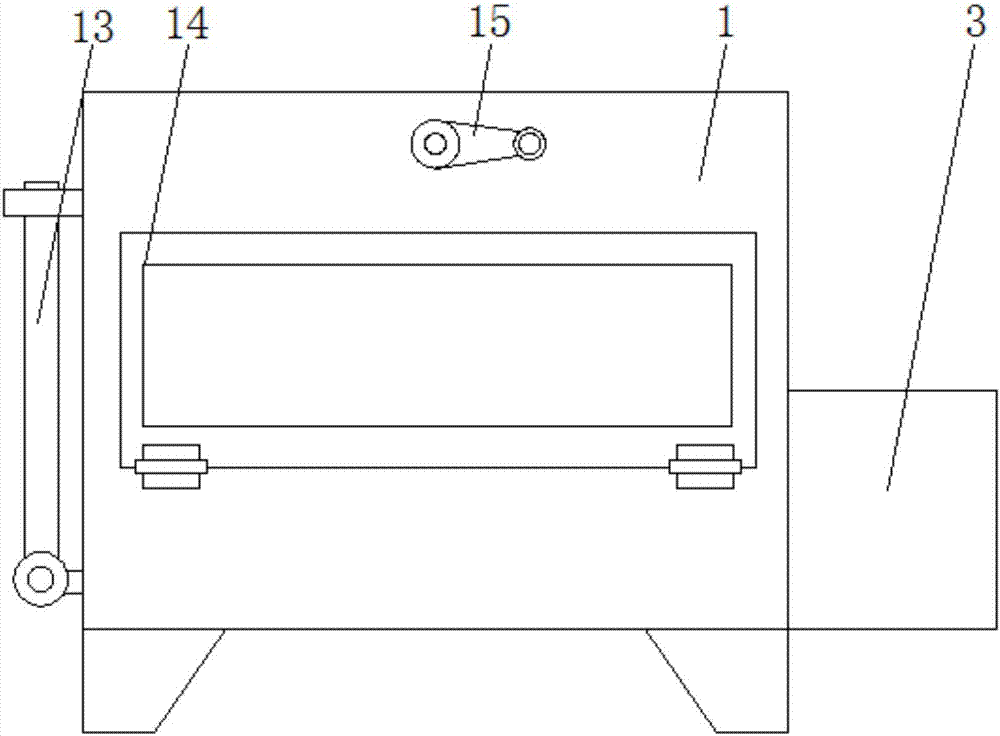

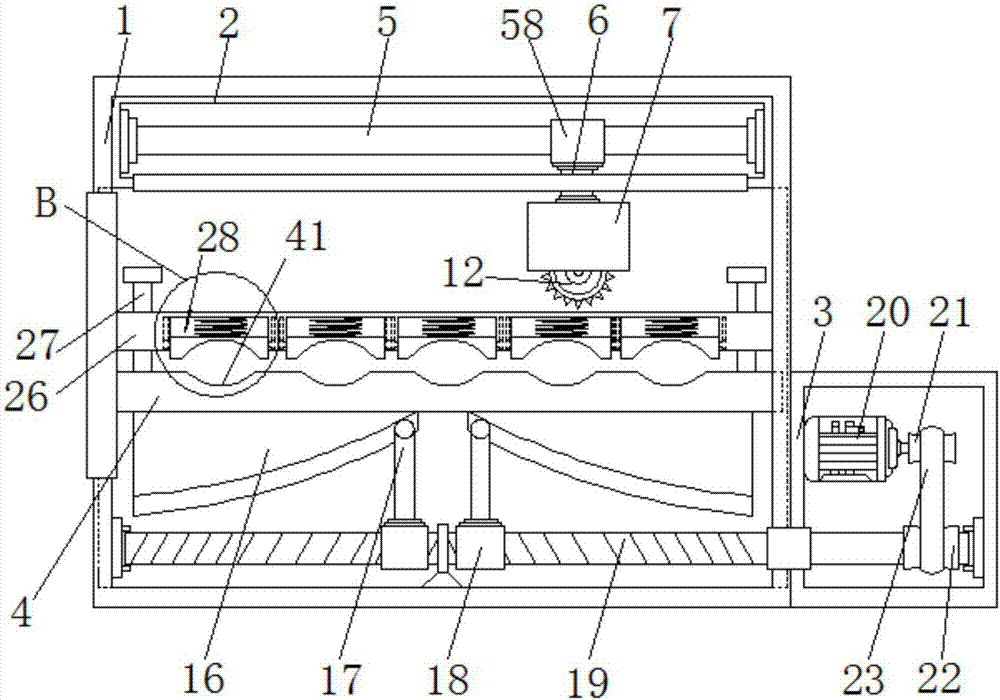

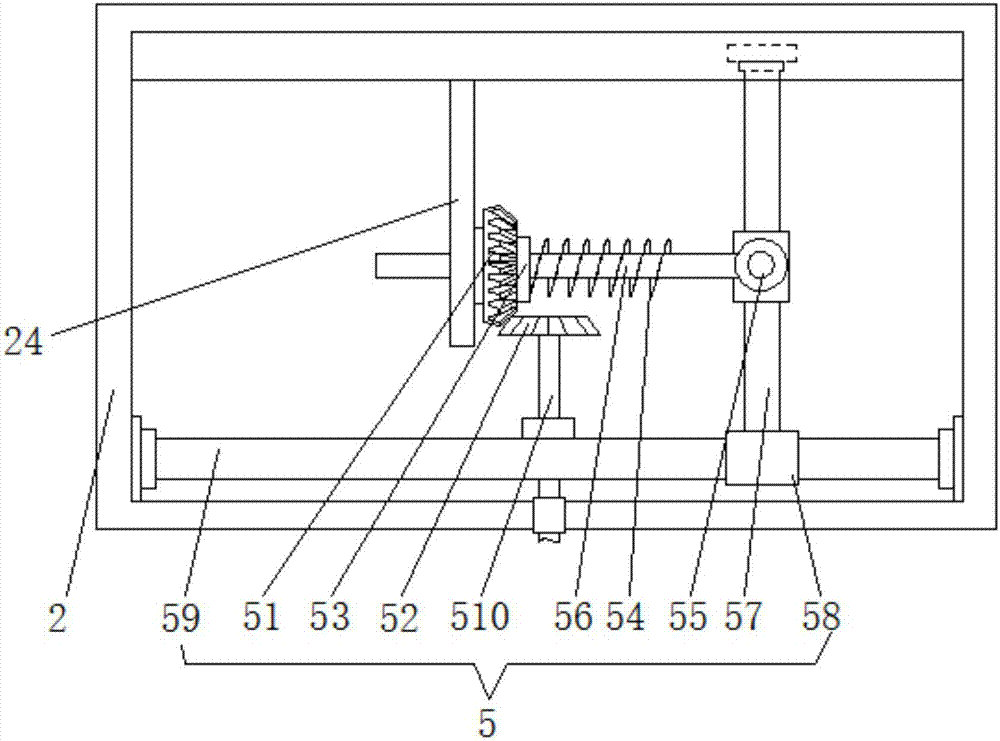

[0032] see Figure 1-4 , the present invention provides a technical solution: a high-efficiency building timber cutting device, comprising a box body 1, a top box 2 is fixedly connected to the top of the inner wall of the box body 1, and a bottom box 3 is fixedly connected to the bottom of the right side of the box body 1, And the two sides of the inner wall of the box body 1 are slidingly connected with a placement table 4, the inside of the top box 2 is provided with a mobile device 5, and the bottom of the mobile device 5 is fixedly connected with a connecting plate 6, and the bottom of the connecting plate 6 runs through the top box 2 And extend to the bottom of the top box 2 , the bottom of the top box 2 is provided with a through hole matching with the connecting plate 6 , and the bottom of the connecting plate 6 is fixedly connected with the motor box 7 .

[0033] The left side of casing 1 is rotatably connected with a first casing door 13, which is convenient for clean...

Embodiment 2

[0040] This embodiment is except the technical characterictic of embodiment 1. Such as Figure 5 As shown, the power mechanism of the present embodiment is a third motor 25, and the third motor 25 is installed on the inner wall of the box body 1, and the outside of the box body 1 is also provided with a forward rotation switch 251 for controlling the clockwise rotation and reverse rotation of the third motor 25, and reverse rotation. switch 252 . When working, press the forward rotation switch 251 by hand, and the cutter 12 will continue to move left or right. opposite action.

Embodiment 3

[0042] This embodiment is except the technical feature of embodiment 1 or embodiment 2. Such as figure 2 , Figure 6 , Figure 7 As shown, a briquetting block 26 and a fixing screw 27 are arranged above the placement table 4 of the present embodiment, and the fixing screw 27 passes through the briquetting block 26 to fix the briquetting block 26 and the placement table 4; the briquetting block 26 is equipped with several pressing devices 28 , the front end of the pressing block 26 is provided with a slot (261), and the pressing device 28 is installed in the slot 261; There is an upper pressing block slider 282, and an upper pressing block chute 283 is arranged in the slot 261, and the pressing block sliding block 282 slides in the upper pressing block chute 283; the return spring 285 is fixed on the top of the upper pressing block 284 , the lower end surface of the upper pressing block 284 exceeds the lower end surface of the pressing block 26 .

[0043] The upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com