Scraper mechanism of cold-rolling emulsion magnetic filter

A magnetic filter and emulsion technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of frequent collisions, damage to chain connecting blocks and pins, and inability to discharge iron powder impurities in time. The effect of reducing failure rate and improving operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

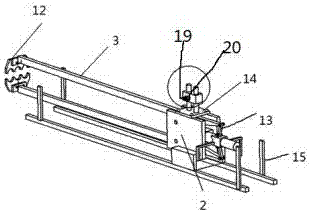

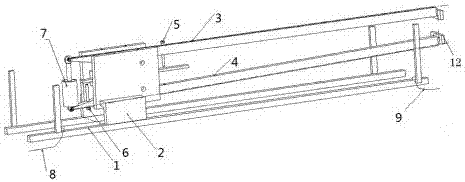

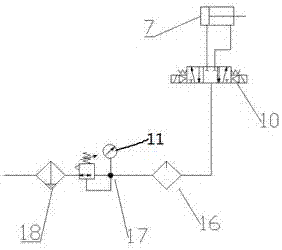

[0020] Refer to attached figure 2 , 3 , a scraper mechanism for a cold-rolled emulsion magnetic filter, comprising a track 1, a car body 2, an upper scraper arm 3, a lower scraper arm 4, an upper top wire 5, a lower top wire 6, a cylinder 7 and a scraper 12, and a car body 2 Set on the track 1, the upper scraper arm 3 and the lower scraper arm 4 are respectively fixed on the car body 2 through pin shafts, one end of the upper scraper arm 3 and the lower scraper arm 4 is connected by a cylinder 7, and the upper scraper arm 3 and the lower scraper arm The other end of 4 is respectively provided with a scraper 12, and the upper scraper arm 3 and the lower scraper arm 4 are respectively provided with an upper top wire 5 and a lower top wire 6.

[0021] In this example, refer to the attached figure 2 , the car body 2 can slide on the track 1, the upper scraper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com