Moss stereoscopic greening process

A three-dimensional greening and moss technology, applied in the field of moss three-dimensional greening technology, can solve the problems of lack of water absorption and water retention, lack of necessary nutrients for moss, loss of air-permeable matrix, etc., to achieve on-site construction operations, low maintenance costs, and easy maintenance The effect of pests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

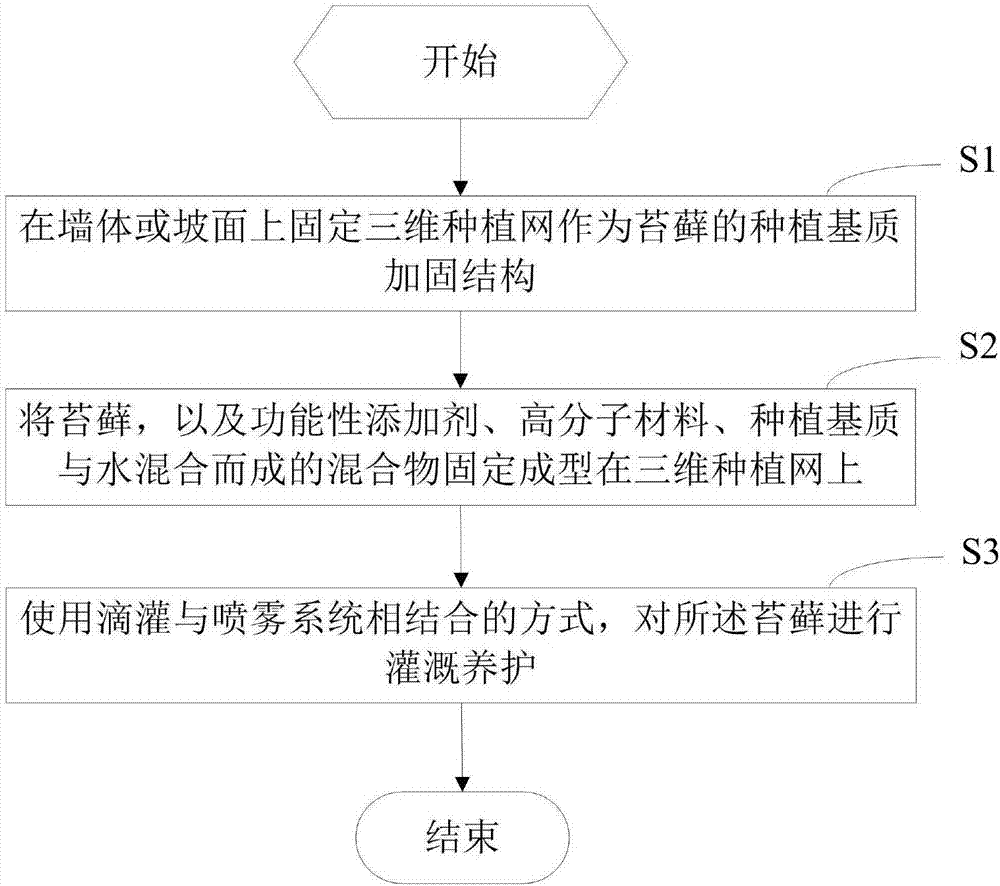

Method used

Image

Examples

specific Embodiment 1

[0047] 2 parts by weight of polyvinyl alcohol, 8 parts by weight of melamine resin, 0.1 parts by weight of ammonium chloride, 0.01 parts by weight of hydrochloric acid, 0.01 parts by weight of carbendazim, 0.005 parts by weight of dodecyltrimethylammonium chloride, 8 parts by weight of Part peat soil, 5 parts by weight of vermiculite powder, 5 parts by weight of moss, and 100 parts by weight of water are uniformly mixed, and after being stirred and filled with air bubbles, it is sprayed on the slope that is fixed with a three-dimensional planting net with a slope of less than 45 degrees. After being fixed and formed, sprinkler irrigation and atomization systems are laid for water supply maintenance, and mossy slopes can be formed in about a month.

specific Embodiment 2

[0048] 10 parts by weight of polyether polyol, 3 parts by weight of isocyanate, 0.01 parts by weight of chlorothalonil, 0.01 parts by weight of silicone oil, 0.001 parts by weight of copper sulfate, 10 parts of diatomaceous earth, 5 parts of sphagnum moss, 2 parts of peat soil, 30 parts of Water and 5 parts of moss are mixed evenly, and then quickly sprayed onto the shady outer wall fixed with the three-dimensional planting net. After the rapid foaming and setting, an irrigation system is laid for water supply maintenance, and a green wall with moss can be obtained in about a month.

[0049] In this embodiment, polyether polyols include at least one polyether polyol with difunctional or trifunctional groups and a molecular weight between 800-5000, and the EO content of each polyether polyol is between 20% and 90%. between. The method described in this embodiment releases carbon dioxide through the reaction of isocyanate and water to achieve the purpose of foaming. At the same ...

specific Embodiment 3

[0050] 10 parts by weight of diatomite, 5 parts by weight of peat soil, 5 parts by weight of sphagnum moss, 40 parts by weight of water, 10 parts by weight of polyurethane prepolymer, 0.1 parts by weight of silicone oil, 0.01 parts by weight of Bordeaux mixture, 0.001 parts by weight of ferrous sulfate Quickly mix and stir evenly, brush or spray on the wall with the three-dimensional planting net fixed, and paste the moss on the brush or spray, after being fixed and formed together, arrange the irrigation system for water supply and maintenance, and the moss greening effect can be quickly obtained .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com