High temperature-resistant polyphenylene sulfide hollow fiber membrane and preparation method thereof

A technology of polyphenylene sulfide and high temperature resistance, which is applied in the field of preparation of filter materials, can solve the problems of low recycling rate, low production efficiency, long process flow, etc., and achieves the effects of high production efficiency, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

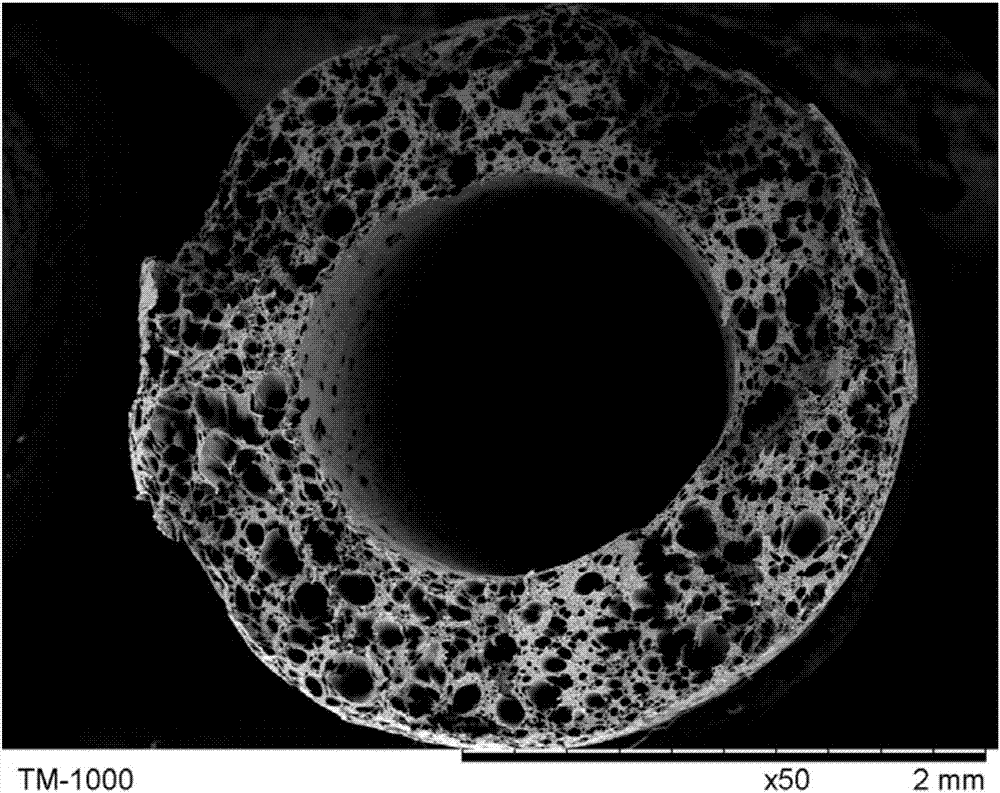

[0027] A method for preparing a high-temperature-resistant polyphenylene sulfide hollow fiber membrane, comprising:

[0028] Step 1, prepare polyphenylene sulfide (PPS) and composite porogen, the mass ratio of polyphenylene sulfide and composite porogen is 50-90:10-50, wherein polyphenylene sulfide accounts for 50% ~90%, the composite porogen accounts for 10%~50%, the two are 100% altogether; Among the present embodiment, weigh the PPS of 900g and the nano CaCO of 100g 3 ;

[0029] Step 2, mix the above-mentioned preparations in a high-speed mixer until uniform;

[0030] Step 3, send the uniformly mixed stock into the extruder; in this embodiment: the temperature of each zone of the twin-screw extruder is set to: 320°C in the melting zone (the uniformly mixed stock enters the extruder at this temperature), The melt blending zone is 315°C, and the spinneret is 310°C; feed the uniformly mixed preparation feeder into the twin-screw extruder at a feed rate of 4kg / h; inject super...

Embodiment 2

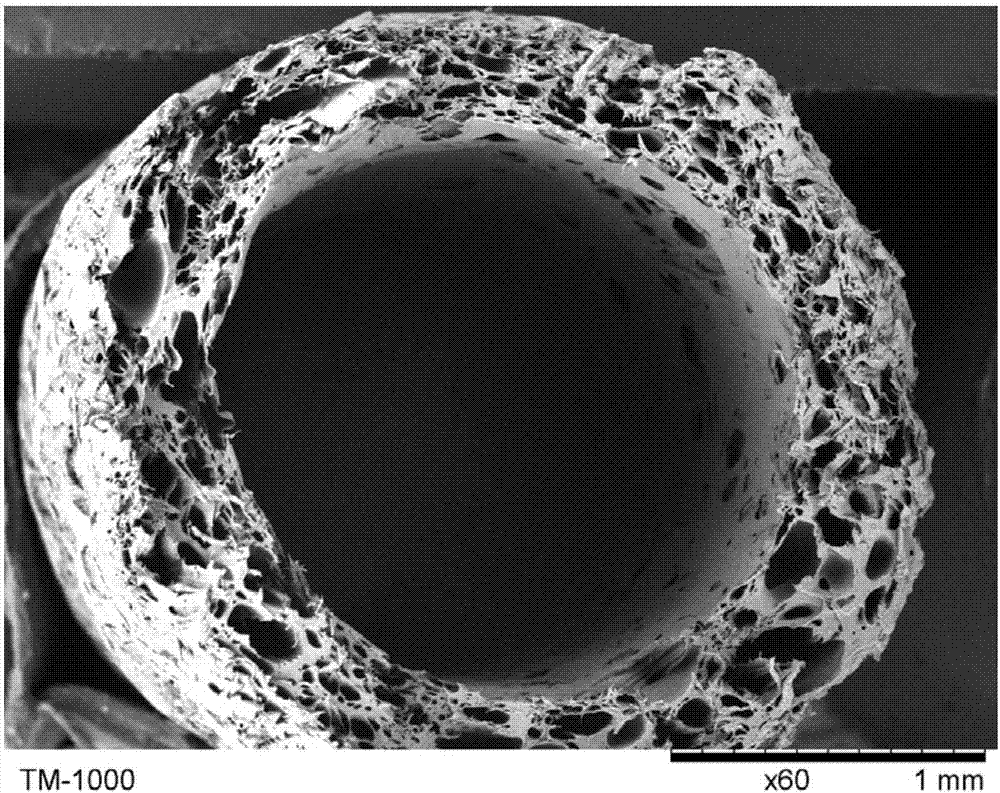

[0035] It differs from Example 1 in that: a method for preparing a high-temperature-resistant polyphenylene sulfide hollow fiber membrane, comprising:

[0036] Step 1, weigh 900g of PPS and 100g of nano-CaCO 3 ;

[0037] Step 2, mix the above-mentioned preparations in a high-speed mixer until uniform;

[0038] Step 3, feeding the uniformly mixed preparations into the extruder; in this embodiment: the temperature of each zone of the twin-screw extruder is set as: melting zone 290°C, melt blending zone 290°C, spinneret 270°C; Feed the uniformly mixed preparation feeder into the twin-screw extruder at a feeding speed of 4kg / h; inject supercritical carbon dioxide into the third heating zone of the extruder, the input flow rate is 2ml / min, and the injection temperature is 60°C , pressure 10MPa. When the supercritical carbon dioxide is injected into the extruder by a high-pressure injection pump, the parameters are: temperature 35-65° C., pressure 8-15 MPa, and output flow 0.1-20...

Embodiment 3

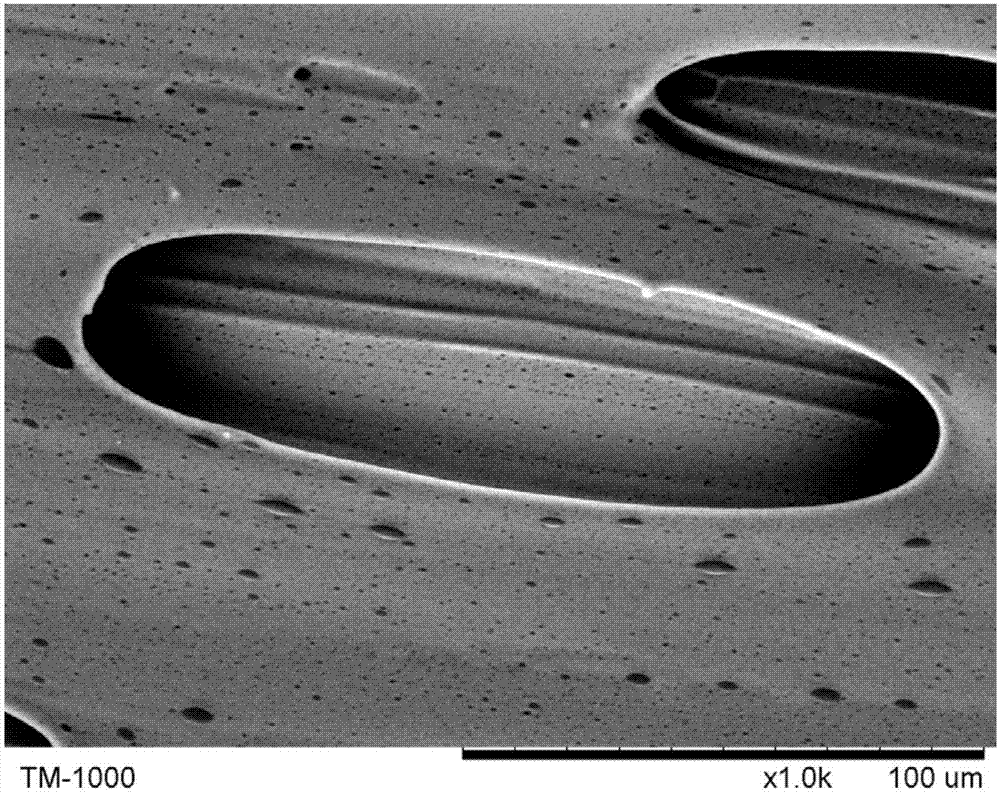

[0044] It differs from Example 1 in that: Step 1: Weigh 900g of PPS and 100g of nano-SiO 2 ;

[0045] Step 2, mix the above-mentioned preparations in a high-speed mixer until uniform;

[0046] Step 3, feeding the uniformly mixed preparations into the extruder; in this embodiment: the temperature of each zone of the twin-screw extruder is set as: melting zone 290°C, melt blending zone 290°C, spinneret 260°C; Feed the uniformly mixed preparation feeder into the twin-screw extruder at a feeding speed of 3kg / h; inject supercritical carbon dioxide into the third heating zone of the extruder, the input flow rate is 5ml / min, and the injection temperature is 40°C , pressure 12MPa.

[0047] Step 4, the uniformly mixed preparation and supercritical carbon dioxide are melt-blended in the extruder, and after melt-blending, they are extruded through the hollow spinneret assembly of the extruder, and the extruded parts are stretched, drawn, cooled and shaped, and then subjected to subsequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com