Positive electrode material for flexible lithium-sulfur battery

A technology for lithium-sulfur batteries and cathode materials, which is applied in the field of electrochemical applications and can solve problems such as uneven loading of cathode sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of film

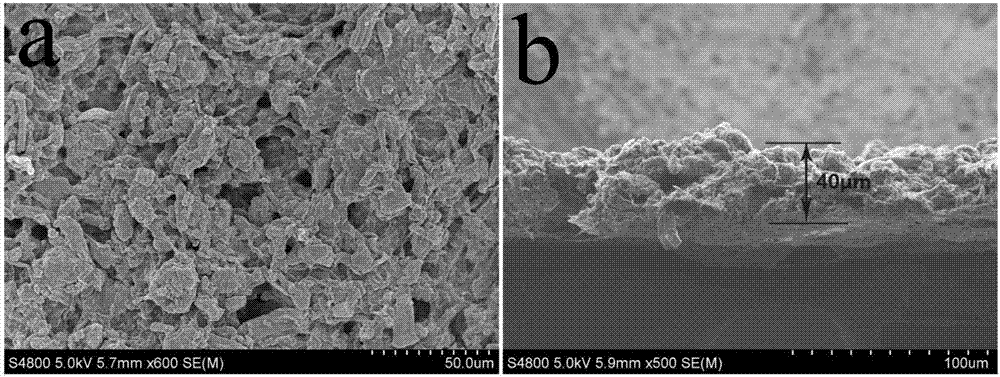

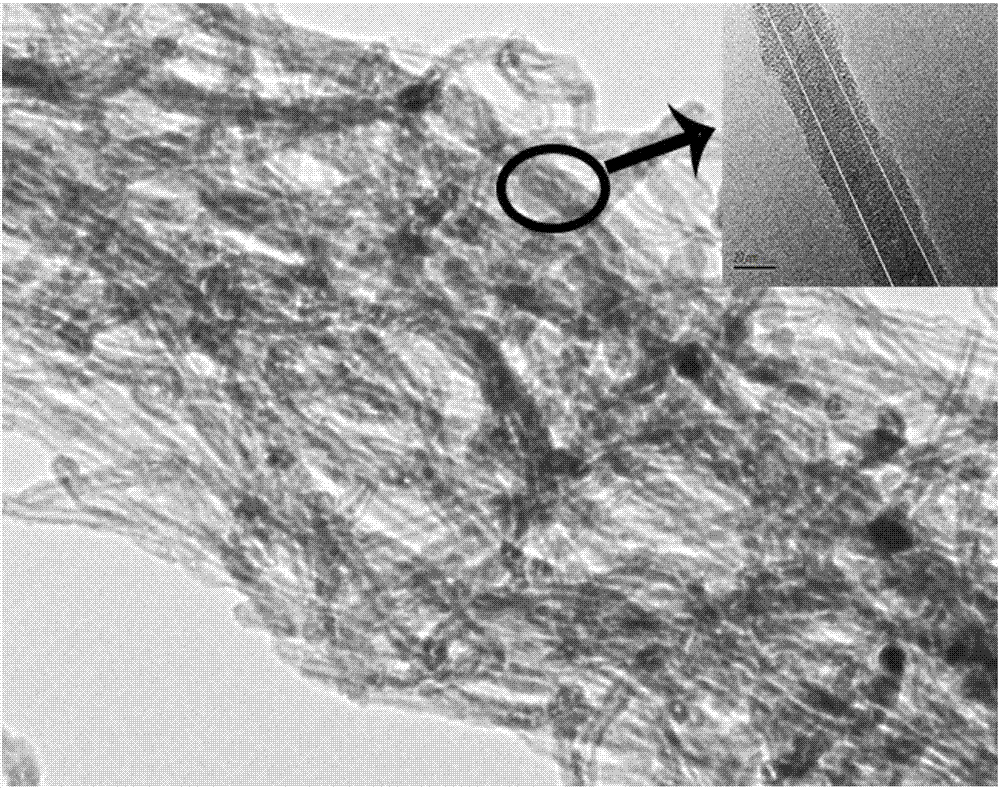

[0047] At room temperature, add 0.2 g of carbon nanotubes to 100 ml of Tris-HCl buffer solution with a pH value of 8.5 dissolved in 0.2 g of dopamine hydrochloride, stir magnetically for 8 h to mix evenly, and filter with a microporous membrane with an average pore size of 0.22 μm , to obtain a powder; grind the powder, PEDOT:PSS and DMSO in a mortar for 30 minutes and mix them evenly to obtain a slurry, which is coated on a silicon plate with a coating thickness of 150 μm, dried at room temperature for 24 hours, and used Rinse with deionized water to remove impurities and fall off from the substrate to obtain a negative film.

[0048] Wherein, the mass ratio of powder to PEDOT:PSS is 4:1, and the volume ratio of PEDOT:PSS to DMSO is 25:3.

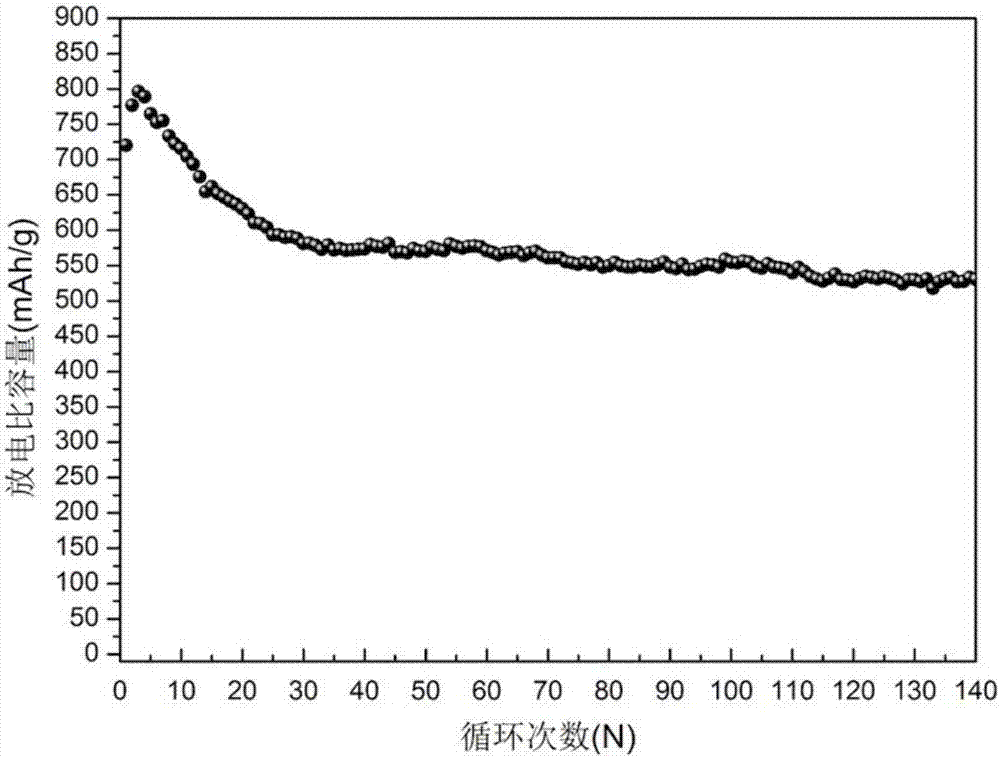

[0049] (2) Sulfur loading

[0050]In a glove box filled with an argon atmosphere with a purity of 99%, dissolve 0.182g of sulfur elemental substance in 11.5ml of toluene, stir for 30min to fully dissolve ...

Embodiment 2

[0060] (1) Preparation of film

[0061] At room temperature, add 0.1 g of carbon nanotubes and 0.1 g of graphene into 100 ml of Tris-HCl buffer solution with a pH value of 8.5 dissolved in 0.2 g of dopamine hydrochloride, stir magnetically for 24 h and mix evenly. The pore filter membrane is suction-filtered to obtain the powder; the powder, PEDOT:PSS and DMSO are ground and mixed in a mortar for 30 minutes to obtain a slurry, and the slurry is coated on a silicon plate with a coating thickness of 150 μm. Dry for 24 hours, rinse with deionized water to remove impurities, and fall off from the substrate to obtain a negative film.

[0062] Wherein, the mass ratio of powder to PEDOT:PSS is 1:9, and the volume ratio of PEDOT:PSS to DMSO is 5:1.

[0063] (2) Sulfur loading

[0064] In a glove box filled with an argon atmosphere with a purity of 99%, dissolve 0.182g of sulfur elemental substance in 11.5ml of toluene, stir for 30min to dissolve and obtain a solution, absorb it with...

Embodiment 3

[0074] (1) Preparation of film

[0075] At room temperature, add 0.2 g of carbon nanotubes to 100 ml of Tris-HCl buffer solution with a pH of 7.5 dissolved in 0.2 g of dopamine hydrochloride, stir for 4 h to mix evenly, and filter with a microporous membrane with an average pore size of 0.22 μm , to obtain a powder; grind the powder, PEDOT:PSS and DMSO in a mortar for 30 minutes and mix them evenly to obtain a slurry, which is coated on a silicon plate with a coating thickness of 500 μm, dried at room temperature for 24 hours, and used Rinse with deionized water to remove impurities and fall off from the substrate to obtain a negative film.

[0076] Wherein, the mass ratio of powder to PEDOT:PSS is 1:9, and the volume ratio of PEDOT:PSS to DMSO is 25:1.

[0077] (2) Sulfur loading

[0078] In a glove box filled with an argon atmosphere with a purity of 99%, dissolve 0.182g of sulfur elemental substance in 11.5ml of toluene, stir for 30min to fully dissolve to obtain a soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com