Ink-jet-printing-technology-based preparation method of flexible wireless pressure detection system

A detection system, inkjet printing technology, applied in the measurement of the property force of the piezoelectric resistance material, the copying/marking method, the printing of the production of special varieties of printed matter, etc., can solve the problem of not being soft enough, and achieve high conductivity , prolong life, strong stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

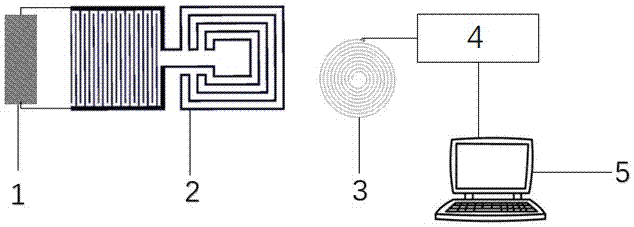

[0033] refer to figure 1 , the present invention includes: a flexible pressure sensor 1, a flexible silver circuit and an antenna 2, a copper coil 3, a processing circuit 4 composed of an impedance matching module and a WiFi chip, and a display terminal 5, the flexible pressure sensor 1 and the flexible silver circuit and The antenna 2 is connected; the processing circuit 4 is connected to the copper coil 3 and the display terminal 5, the flexible silver circuit and the antenna 2 are coupled with the copper coil 3 through electromagnetic induction, and are wirelessly connected within 5-30 cm. The copper coil 3 receives the signal, and the processing circuit 4 performs analog-to-digital conversion, and the digital signal is processed and output to the display terminal through the WiFi chip, and the signal change induced by the copper coil is determined by

[0034] Calculate the change of the pressure that the flexible pressure sensor 1 bears.

[0035] When pressure is applie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com