Preparation method of polyvinyl ether lubricating oil base oil mutually soluble with R32 refrigerant at low temperature and application of polyvinyl ether lubricating oil base oil in refrigeration system

A technology of lubricating base oil and polyvinyl ether, which is applied in the field of lubricating oil for refrigeration systems, can solve problems such as turbidity, and achieve the effects of good mutual solubility, excellent compatibility and good mutual solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

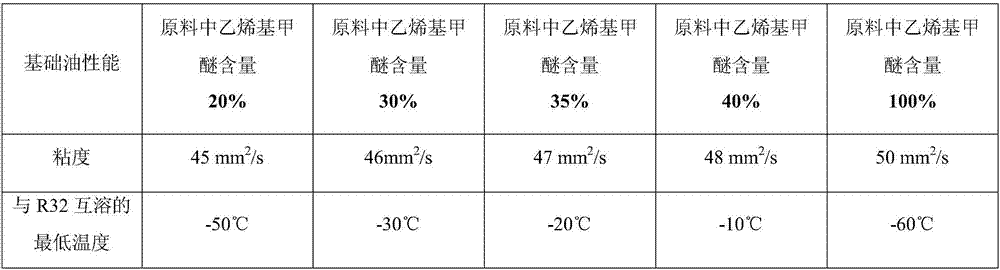

Embodiment 1

[0035] S1, mixing: take 20% of vinyl methyl ether and 80% of vinyl ether and mix evenly;

[0036] S2. Polymerization: Under the protection of nitrogen at normal pressure and 20-30°C, add a mixture of vinyl methyl ether and vinyl ethyl ether and a catalyst of boron trifluoride ether with a weight ratio of 0.1% in the reaction kettle. Carry out polymerization reaction under, obtain polymerization product A;

[0037] S3. Hydrogenation: Raise the pressure in the reactor to 5MPa-15MPa, and the temperature is 100-200°C, add a nickel-based or noble metal catalyst, and complete the hydrogenation reaction under the action of hydrogen purge and catalyst, so that the polymerization product A The double bond is saturated to obtain product B;

[0038] S4. Distillation: The product B after hydrogenation is subjected to vacuum distillation, and the light components are distilled off to obtain a lubricating oil base oil. The prepared lubricating oil base oil is composed of a copolymer of vin...

Embodiment 2

[0046] S1, mixing: take 30% vinyl methyl ether and 70% vinyl ether and mix evenly;

[0047] S2. Polymerization: Under the protection of nitrogen at normal pressure and 20-30°C, add a mixture of vinyl methyl ether and vinyl ethyl ether and a catalyst of boron trifluoride ether with a weight ratio of 0.1% in the reaction kettle. Carry out polymerization reaction under, obtain polymerization product A;

[0048]S3. Hydrogenation: Raise the pressure in the reactor to 5MPa-15MPa, and the temperature is 100-200°C, add a nickel-based or noble metal catalyst, and complete the hydrogenation reaction under the action of hydrogen purge and catalyst, so that the polymerization product A The double bond is saturated to obtain product B;

[0049] S4. Distillation: The product B after hydrogenation is subjected to vacuum distillation, and the light components are distilled off to obtain a lubricating oil base oil. The lubricating oil base oil obtained is composed of polyvinyl methyl ether, p...

Embodiment 3

[0057] S1, mixing: take 35% of vinyl methyl ether and 65% of vinyl ether and mix evenly;

[0058] S2. Polymerization: Under the protection of nitrogen at normal pressure and 20-30°C, add a mixture of vinyl methyl ether and vinyl ethyl ether and a catalyst of boron trifluoride ether with a weight ratio of 0.1% in the reaction kettle. Carry out polymerization reaction under, obtain polymerization product A;

[0059] S3. Hydrogenation: Raise the pressure in the reactor to 5MPa-15MPa, and the temperature is 100-200°C, add a nickel-based or noble metal catalyst, and complete the hydrogenation reaction under the action of hydrogen purge and catalyst, so that the polymerization product A The double bond is saturated to obtain product B;

[0060] S4. Distillation: Distill the hydrogenated product B under reduced pressure to remove light components to obtain lubricating oil base oil.

[0061] or

[0062] S1', Homopolymerization: Under the protection of nitrogen at normal pressure an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com