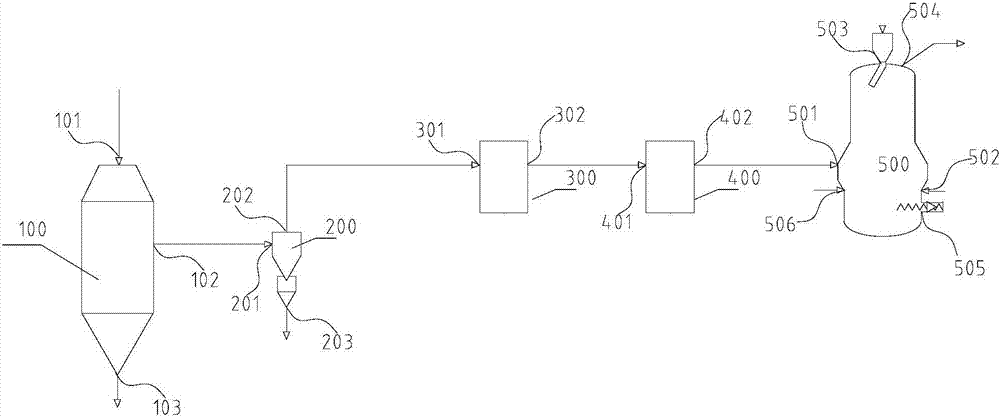

System and method for treating low-rank coal

A low-rank coal, inlet technology, applied in the removal of gas pollutants, special forms of dry distillation, furnace types, etc., can solve the problems of high metallurgical process cost, large environmental load, violent secondary reaction of oil and gas, etc., to improve resources. Utilization rate, CO2 emission reduction, high effective gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

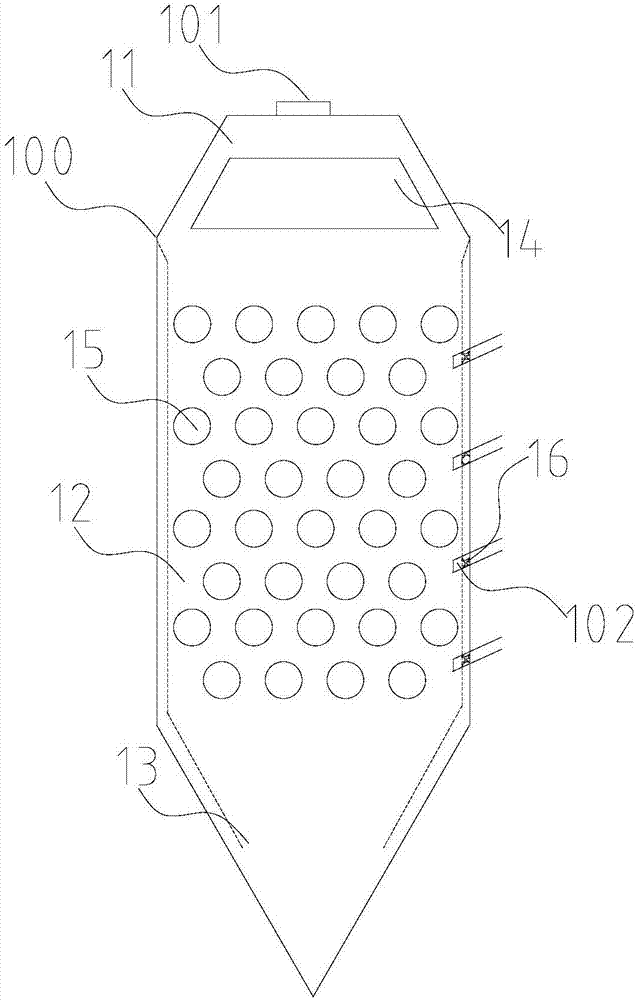

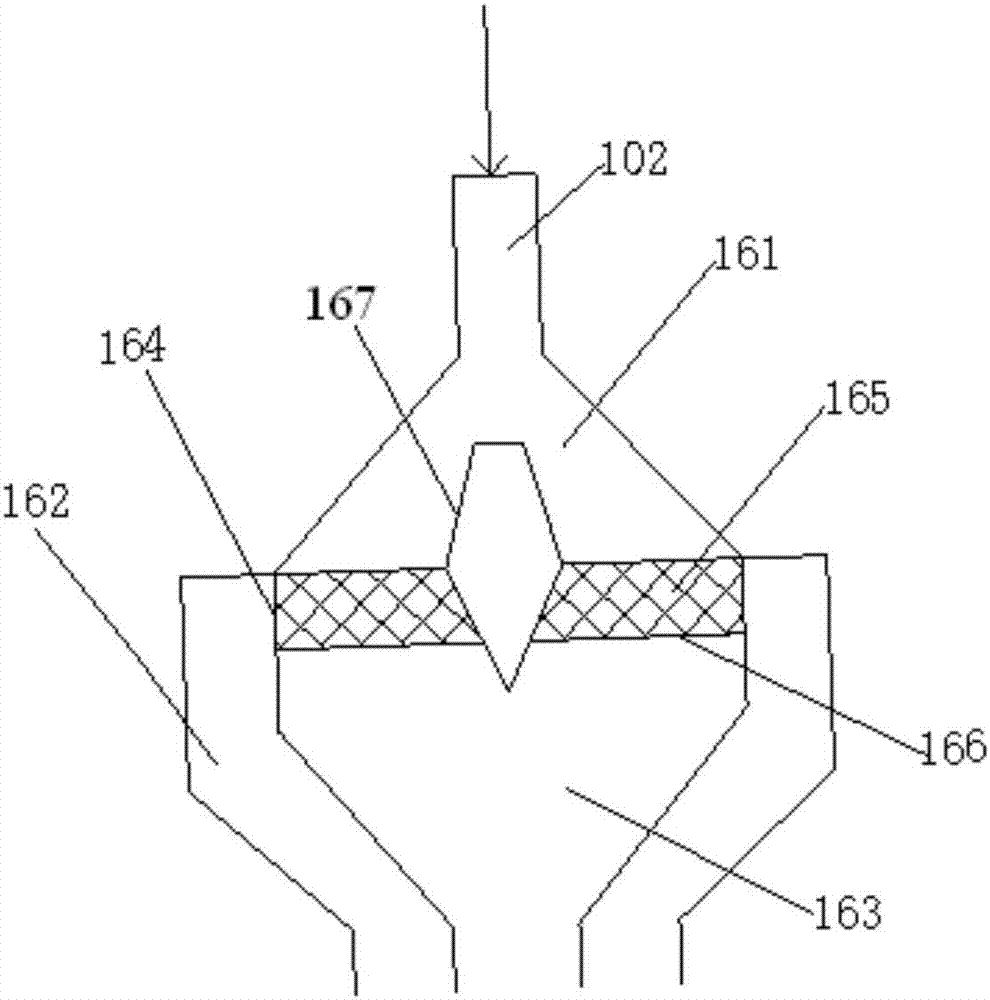

[0088] Supply lignite as pyrolysis raw material to the rapid pyrolysis device for rapid pyrolysis treatment at 900°C, and the obtained pyrolysis gas (composition shown in Table 1) is discharged through the pyrolysis gas outlet on the side wall of the pyrolysis zone After dust removal by particle dust removal unit (after dust removal, the composition of pyrolysis gas is 86.59v%, CH 4 =4.17v%2 / CO=1.25, different dust removal methods are shown in Table 2) are supplied to cyclone dust collector and electrostatic precipitator in turn to obtain dedusted gas and dust particles, and then the dedusted gas obtained in the dust collector is supplied to the desulfurization and decarbonization device The desulfurization and decarbonization treatment is carried out in the dedusting gas. The gas after dedusting is firstly desulfurized by circulating suspension semi-dry flue gas desulfurization technology. Purified gas is obtained. A part of the purified gas is supplied to the heating devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com