Multifunctional artificial board and preparation method thereof

A kind of wood-based panel, multi-functional technology, applied in the direction of coating, to achieve the effect of good compatibility, improve mechanical properties, and promote compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

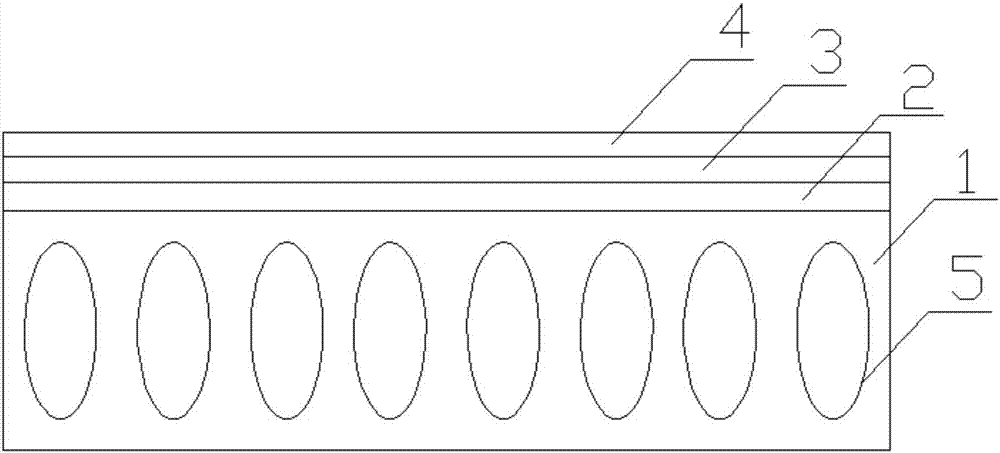

[0050] Such as figure 1 As shown, a wood-based panel includes a base layer 1 and a UV primer layer 2 arranged sequentially from inside to outside above the base layer 1, a thermal transfer decoration layer 3 and a UV topcoat layer 4, and a wall along the base layer 1 is provided inside the board body of the base layer 1. Several through-holes 5 with elliptical cross-sections uniformly arranged in the length direction, the distance between the through-holes is 1mm.

[0051] Wherein, the base layer 1 has a thickness of 10 mm and includes the following raw materials in parts by weight:

[0052] 80 parts of polyvinyl chloride,

[0053] 20 parts of chlorinated polyethylene,

[0054] 5 parts of vinyl chloride-vinyl acetate copolymer resin,

[0055] 15 parts of light calcium,

[0056] 30 parts of kaolin,

[0057] 3 parts of PE wax,

[0058] 5 parts of stearic acid,

[0059] 3 parts of dioctyl phthalate;

[0060] Among them, the particle size of kaolin is 800 mesh.

[0061] T...

Embodiment 2

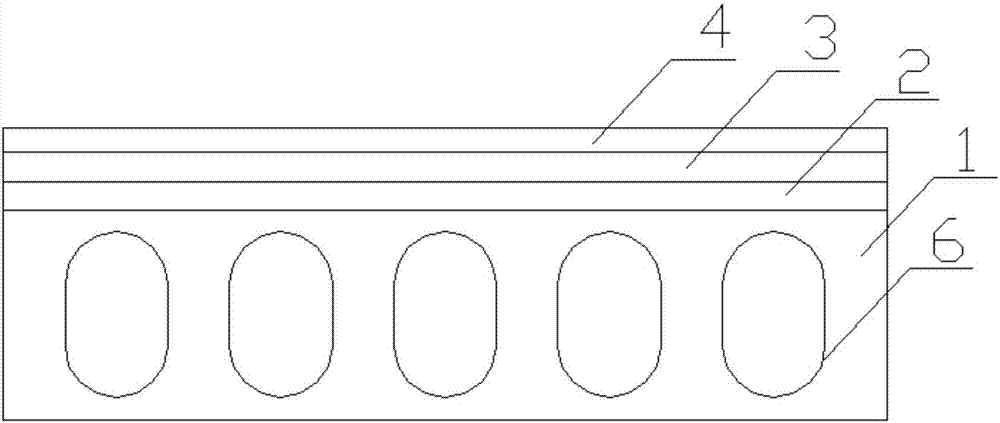

[0070] Such as figure 2 As shown, a wood-based panel includes a base layer 1 and a UV primer layer 2 arranged sequentially from inside to outside above the base layer 1, a thermal transfer decoration layer 3 and a UV topcoat layer 4, and a wall along the base layer 1 is provided inside the board body of the base layer 1. Several through-holes 6 with a waist-shaped cross-section arranged uniformly in the length direction, and the distance between the through-holes is 5 mm.

[0071] Wherein, the thickness of the base layer 1 is 20mm, including the following raw materials in parts by weight:

[0072] 85 parts of polyvinyl chloride,

[0073] Chlorinated polyethylene 18 parts,

[0074] 6 parts of vinyl chloride-vinyl acetate copolymer resin,

[0075]20 parts of light calcium,

[0076] 25 parts of kaolin,

[0077] 3 parts of PE wax,

[0078] 4 parts stearic acid,

[0079] Dioctyl phthalate 4 parts,

[0080] 1 part of colorant;

[0081] Wherein, the pigment is lemon eucalyp...

Embodiment 3

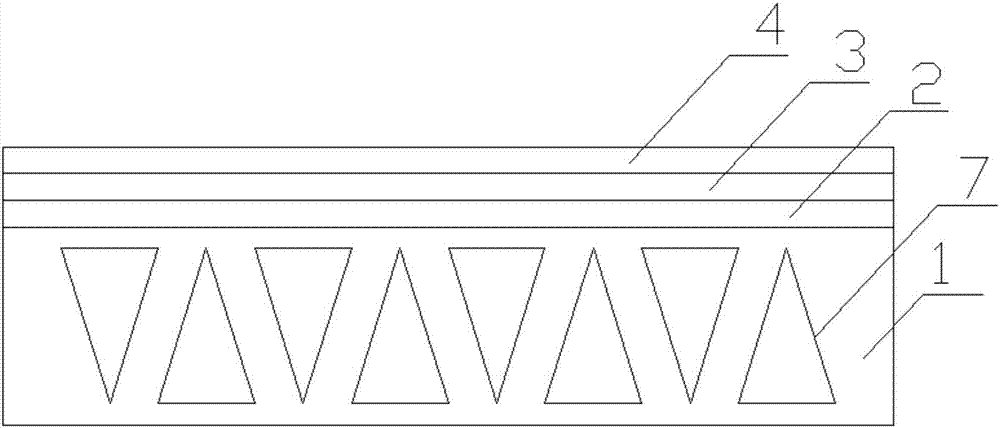

[0091] Such as image 3 As shown, a wood-based panel includes a base layer 1 and a UV primer layer 2 arranged sequentially from inside to outside above the base layer 1, a thermal transfer decoration layer 3 and a UV topcoat layer 4, and a wall along the base layer 1 is provided inside the board body of the base layer 1. Several through holes 7 with triangular cross-sections uniformly arranged in the length direction, regular triangular through holes and inverted triangular through holes are arranged alternately, and the distance between the triangular through holes (the distance between adjacent two waists of two adjacent triangles) is 10mm.

[0092] Wherein, the base layer 1 has a thickness of 30 mm and includes the following raw materials in parts by weight:

[0093] 90 parts of polyvinyl chloride,

[0094] Chlorinated polyethylene 15 parts,

[0095] 8 parts of vinyl chloride-vinyl acetate copolymer resin,

[0096] 23 parts of light calcium,

[0097] 22 parts of kaolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com