Preparation method of high-resilience rubber material and hemorrhoid ligation rubber gasket

A rubber material with high resilience technology, applied in the rubber field, it can solve the problems of vulcanization delay, inability to recycle, and hardening of the mixed rubber, so as to enhance the resilience and strength, block the blood flow of hemorrhoids, and reduce the permanent deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

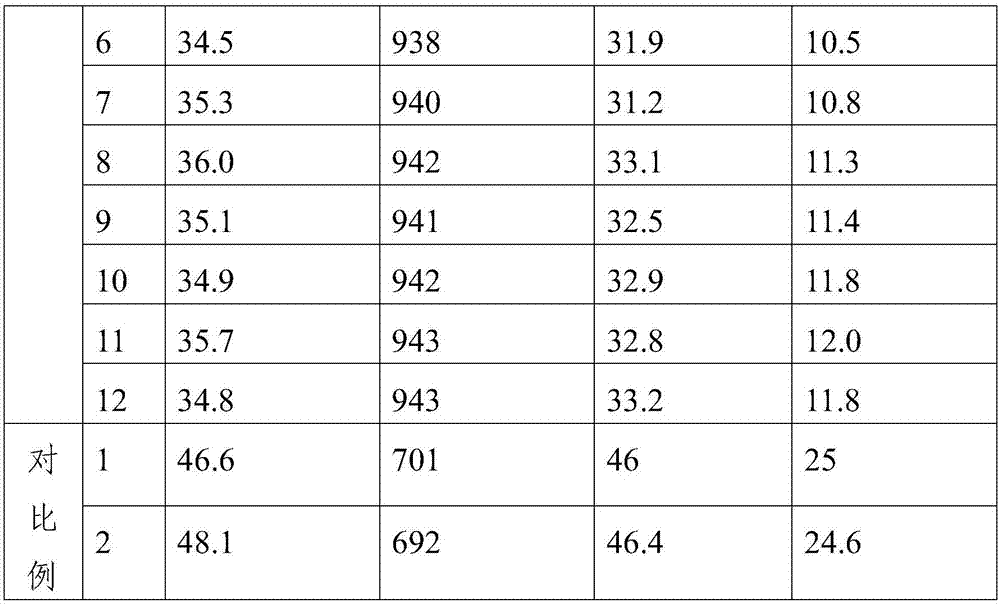

Examples

Embodiment 1

[0033] Embodiment 1 The preparation method of a high-resilience rubber material, including the steps of banburying, kneading, chipping, and vulcanization; the banburying time is 4 minutes, and the banburying temperature is 88 ° C; the kneading time is 16 min, and the kneading temperature is 88 ° C; vulcanization The duration is 300s, and the vulcanization temperature is 140°C;

[0034] The raw material composition of the high resilience rubber material includes: 100 parts of natural rubber, 1.2 parts of stearic acid, 4 parts of accelerator, 0.3 parts of anti-aging agent, and 8 parts of vulcanizing agent;

[0035] Among them, the accelerator is N-tert-butyl-2-benzothiazole sulfenamide, the anti-aging agent is anti-aging agent 445, the vulcanizing agent is a combination of elemental sulfur and zinc oxide, and the weight ratio of the two components is 1:1 .

Embodiment 2

[0037] The difference between Example 2 and Example 1 is that the banburying time is 8 minutes, and the banburying temperature is 72°C; the milling time is 24 minutes, and the milling temperature is 72°C; the vulcanization time is 250s, and the vulcanization temperature is 160°C

Embodiment 3

[0039] The difference between Example 3 and Example 2 is that the banburying time is 6 minutes, and the banburying temperature is 80°C; the milling time is 20 minutes, and the milling temperature is 80°C; the vulcanization time is 280s, and the vulcanization temperature is 150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com