Polymer polyol and composition thereof and application

A polyol and polymer technology, applied in optical components, polyurea/polyurethane coatings, instruments, etc., can solve problems such as increased manufacturing costs, corrosion, and economic losses for manufacturers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

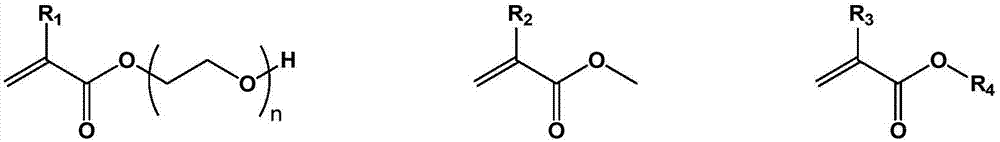

[0043] Formula I A 、II A 、III A Shown compound and diethylene glycol butyl ether are placed in the reactor with stirring and heating device, feed nitrogen into the reactor, start stirring and heating device, dropwise add azobisisobutyronitrile (initiator), And keep at 130°C-140°C for 2-3 hours, cool to room temperature, transfer to a suitable container, evaporate the solvent, and the residue is the target product (abbreviated as "polymer polyol-1").

[0044]

[0045] Take the added material gross weight as 100%, wherein, formula I A The shown compound accounts for 29.5wt%, formula II A The shown compound accounts for 25wt%, formula III A The shown compound accounts for 25 wt%, diethylene glycol butyl ether accounts for 20 wt%, and the initiator accounts for 0.5 wt%.

Embodiment 2

[0047] Except changing the proportion of added material (that is: be 100% with added material gross weight, wherein, formula I A The shown compound accounts for 24.5wt%, formula II A The shown compound accounts for 27.5wt%, formula III A Shown compound accounts for 27.5wt%, diethylene glycol butyl ether accounts for 20wt%, and initiator accounts for 0.5wt%) except that, all the other steps and conditions are identical with embodiment 1, obtain target object (abbreviated as "polymer polyol- 2").

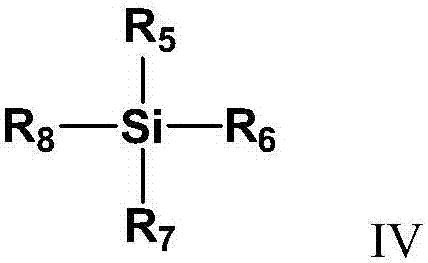

[0048] Preparation of silicone resin (OSEM)

Embodiment 3

[0050] 15 parts by weight of polymer polyol-1, 15 parts by weight of methyltriethoxysilane, 15 parts by weight of ethyl orthosilicate, 25 parts by weight of KH560, 3 parts by weight of KH550 , 6.5 parts by weight of vinyl trimethoxysilane, 10 parts by weight of a mixture of methanol and tert-butanol in equal proportions, 10 parts by weight of water and 0.5 parts by weight of tris(acetylacetonate) aluminum placed in a stirring That is, in the reactor of the temperature control device, nitrogen gas is passed into the reactor, heated and stirred, and kept at 40°C to 50°C for 3 hours to 5 hours, and the added alcohol solvent and water are evaporated under reduced pressure, and the remaining The object is the target object (the silicone resin of the present invention, abbreviated as "OSEM-A").

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com