A kind of magnesium-loaded biochar and its preparation method and application

A biochar, magnesium chloride technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., to achieve the effects of low cost, simple operation, and strong arsenic adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of magnesium-loaded biochar

[0026] This example provides a magnesium-loaded biochar, which is prepared by the following method: dry and pulverize rice straw that has passed through a 2mm sieve and MgCl with a concentration of 0.5mol / L 2 The solutions are mixed, and the ratio of impregnation solution to biomass is 200mL:20g. After soaking for 0.5h, sonicate for 2h, and dry at 80°C.

[0027] Put it into a stainless steel tank with a diameter of 5 cm and a height of 8 cm, compact it and cover it, place it in a box-type electric furnace, raise the temperature to 500 °C at a heating rate of 20 °C / min, keep it for 4 hours, cool to room temperature and take it out.

[0028] The prepared material was filtered and washed 10 times with deionized water, dried at 80°C, and then ground through a 100-mesh sieve to obtain the magnesium-loaded biochar composite material BC-Mg0.5.

Embodiment 2

[0029] Embodiment 2 A kind of magnesium-loaded biochar

[0030] This example provides a magnesium-loaded biochar, which is prepared by the following method: dry and pulverize rice straw that has passed through a 2mm sieve and MgCl with a concentration of 2.0mol / L 2 The solutions are mixed, and the ratio of impregnation solution to biomass is 200mL:20g. After soaking for 0.5h, sonicate for 2h, and dry at 80°C.

[0031] Put it into a stainless steel tank with a diameter of 5 cm and a height of 8 cm, compact it and cover it, place it in a box-type electric furnace, raise the temperature to 500 °C at a heating rate of 20 °C / min, keep it for 4 hours, cool to room temperature and take it out.

[0032] The prepared material was filtered and washed 15 times with deionized water, dried at 80°C, and then ground through a 100-mesh sieve to obtain the magnesium-loaded biochar composite material BC-Mg2.0.

[0033] Effect verification

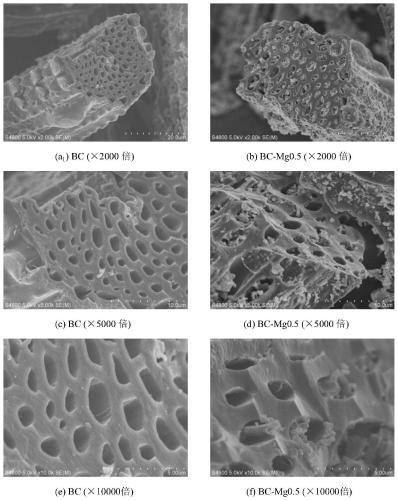

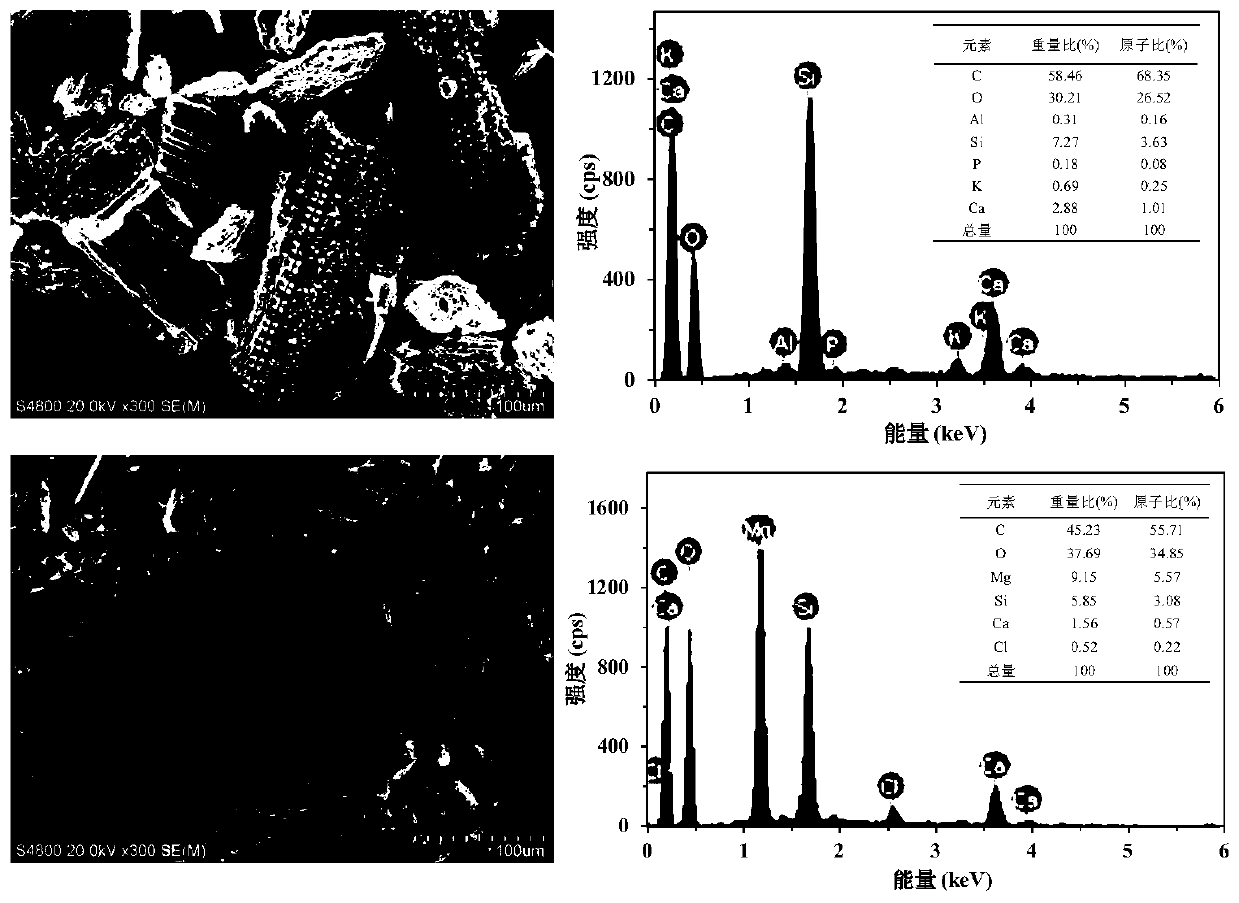

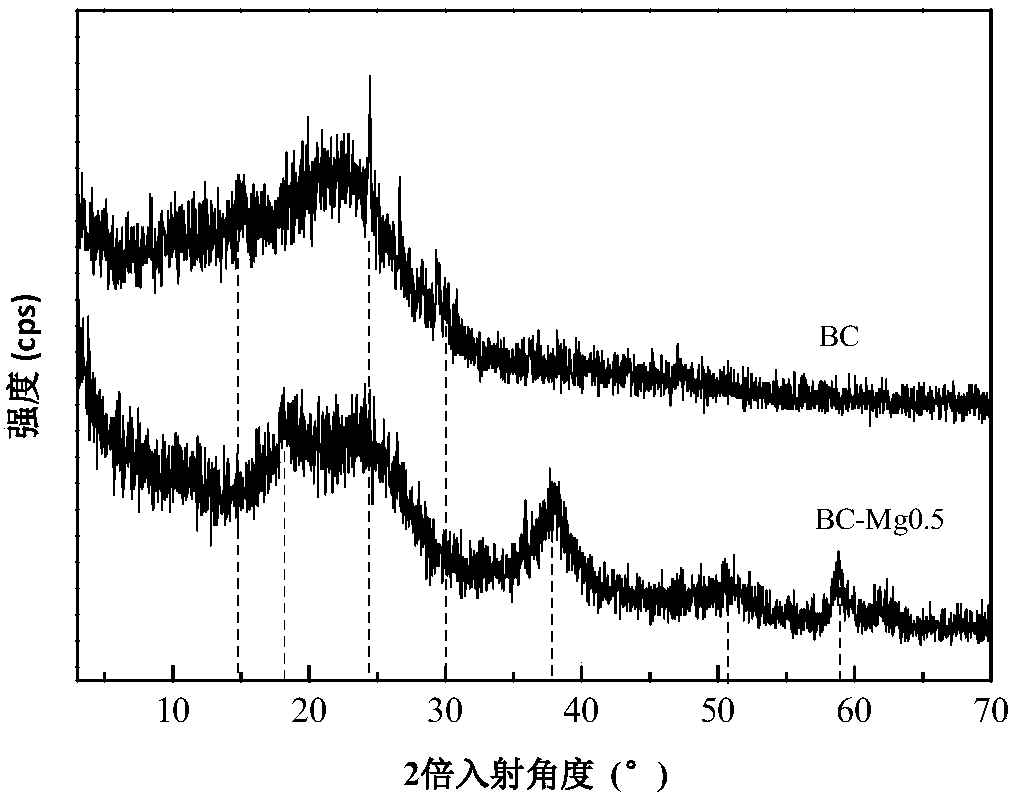

[0034] 1. Physical and chemical properties of adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com