Preparation method for phosphorene-polydopamine composite film

A technology of polydopamine and composite membranes, applied in separation methods, chemical instruments and methods, membranes, etc., can solve the problems of damage, reduction of specific surface area, small specific surface area of phosphorene materials, etc., and achieve excellent separation characteristics and good mechanical properties , Good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of phosphorene-polydopamine composite film, comprising the following steps:

[0023] Step A, coating phosphorene on conductive metal to make phosphorene electrode. Wherein, the conductive metal is at least one of gold, platinum, silver, copper, iron, nickel, zinc, tin, lead, and stainless steel, and the shape of the conductive metal can be sheet, mesh, rod, or wire or frothy.

[0024] Step B. Disperse the dopamine hydrochloride in the phosphate buffer solution evenly to prepare a dopamine hydrochloride electrolyte solution with a concentration of 0.01-0.5 mol / L.

[0025] Step C, placing the phosphorene electrode and the metal counter electrode in the dopamine hydrochloride electrolyte, and reacting by chronopotentiometry, with a current density of 0.1-5mA / cm 2 , The reaction time is 0.1-72 hours, so as to prepare the phosphorene-polydopamine composite film precursor.

[0026] Step D, soaking the phosphorene-polydopamine composite film precursor i...

Embodiment 1

[0030] A preparation method of phosphorene-polydopamine composite film, comprising the following steps:

[0031] Step a1, coating phosphorene on the nickel foam to make a phosphorene electrode.

[0032] Step b1, dispersing the dopamine hydrochloride in the phosphate buffer solution evenly to prepare a dopamine hydrochloride electrolyte solution with a concentration of 0.02 mol / L.

[0033] Step c1, placing the phosphorene electrode and the gold foil counter electrode in the dopamine hydrochloride electrolyte, and reacting by chronopotentiometry with a current density of 0.1mA / cm 2 , The reaction time is 72h, thereby making the phosphorene-polydopamine composite film precursor;

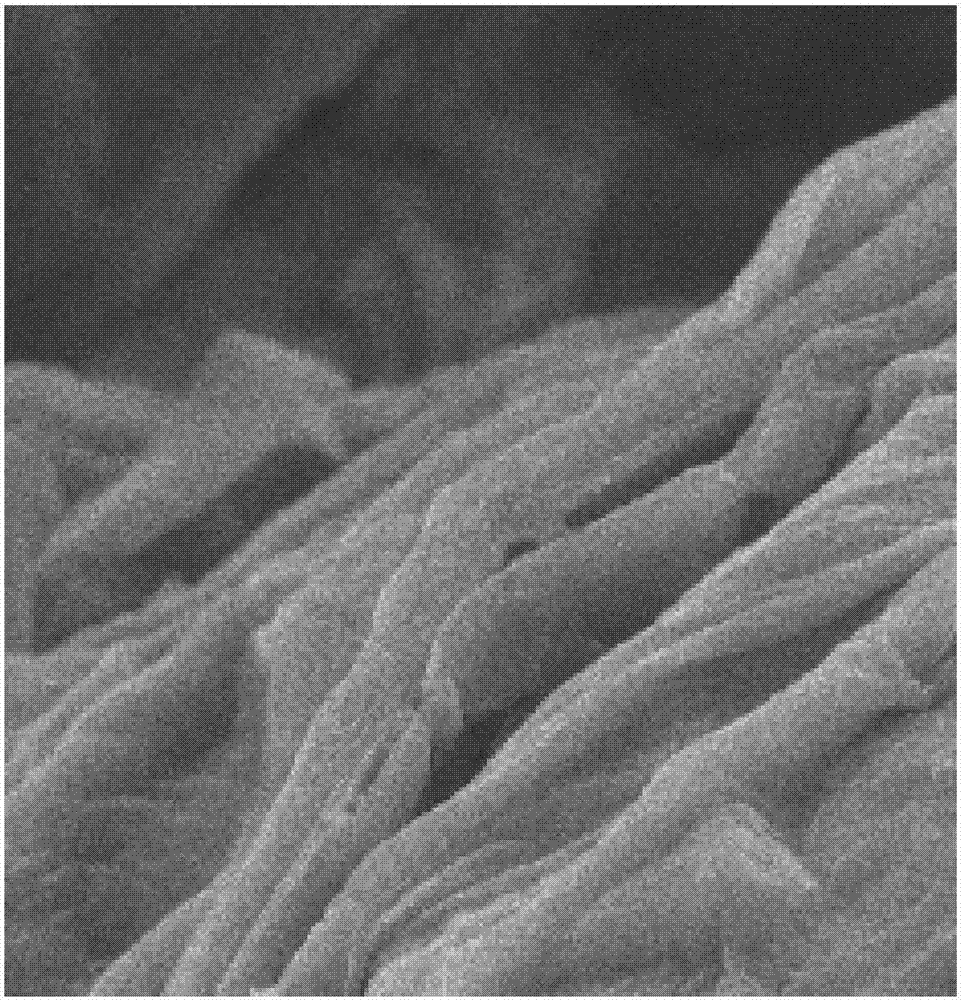

[0034] Step d1, soaking the phosphorene-polydopamine composite membrane precursor in a hydrochloric acid solution with a pH value of 0.001 for 0.2h, then performing solid-liquid separation, and drying the solid obtained by solid-liquid separation, so as to obtain the following: figure 1 The phosphoren...

Embodiment 2

[0036] A preparation method of phosphorene-polydopamine composite film, comprising the following steps:

[0037] Step a2, coating phosphorene on aluminum foil to make a phosphorene electrode.

[0038] Step b2, dispersing the dopamine hydrochloride in the phosphate buffer solution evenly to prepare a dopamine hydrochloride electrolyte solution with a concentration of 0.1 mol / L.

[0039] Step c2, placing the phosphorene electrode and the aluminum foil counter electrode in the dopamine hydrochloride electrolyte, and reacting by chronopotentiometry with a current density of 0.5mA / cm 2 , The reaction time is 60h, thereby making phosphorene-polydopamine composite film precursor;

[0040] Step d2, soaking the phosphorene-polydopamine composite film precursor in a sulfuric acid solution with a pH value of 0.01 for 6 hours, then performing solid-liquid separation, and drying the solid obtained by solid-liquid separation, thereby preparing phosphorene- Polydopamine composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com