Styptic powder and preparation method thereof

A technology of hemostatic powder and starch, applied in the directions of pharmaceutical formulation, surgery, drug delivery, etc., can solve the problems of unfavorable industrial production, contain many impurities, complicated steps, etc., and achieve the effects of easy industrial operation, reduction of impurity content, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

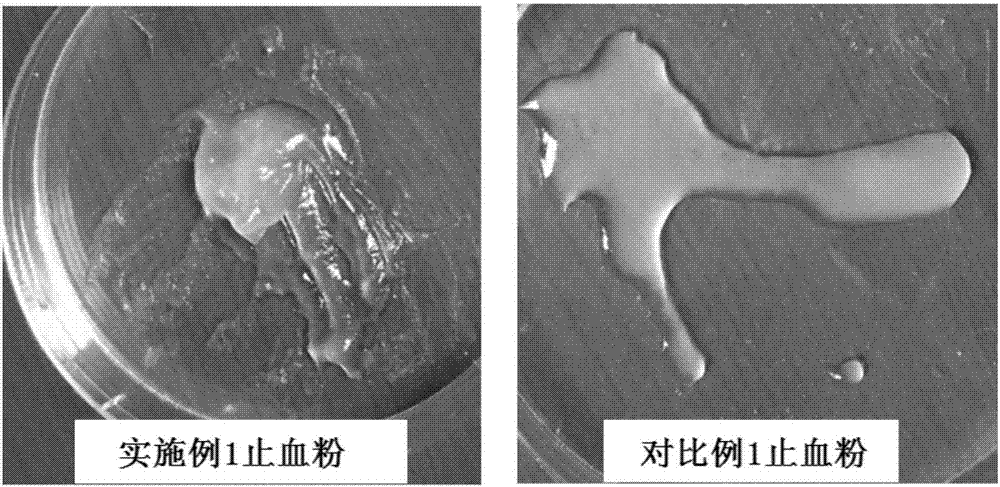

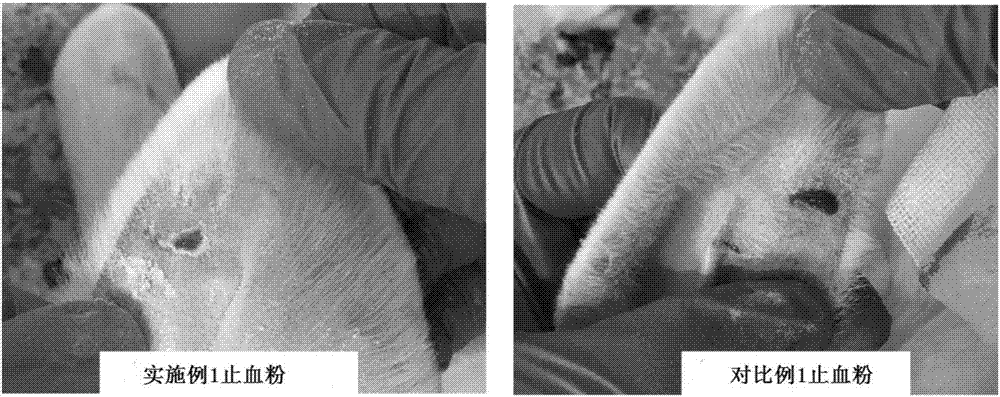

Embodiment 1

[0037] A kind of hemostatic powder, its preparation comprises the steps:

[0038] 1) Preparation of etherified starch: Dissolve 6g of hydroxypropyl starch in 200mL of deionized water, 4g of sodium hydroxide in 40mL of deionized water, and 8g of 3-chloro-2-hydroxypropyltrimethylammonium chloride. In 20mL deionized water; successively add the aqueous solution of NaOH and the aqueous solution of 3-chloro-2-hydroxypropyltrimethylammonium chloride dropwise to the aforementioned hydroxypropyl starch solution, and stir and react at 50°C for 24h; After the completion, precipitate with absolute ethanol, wash several times, and obtain etherified starch with a substitution degree of 5-30% after vacuum drying;

[0039] 2) Weigh 0.5 g of the etherified starch obtained in the above step 1) and dissolve it in deionized water, stir evenly, and adjust the pH to 12 with ammonia water to obtain a starch suspension;

[0040] 3) Measure 100mL of n-hexane, add 2.34g of Span 60, and emulsify to obt...

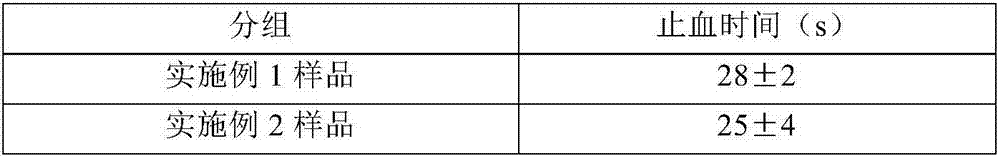

Embodiment 2

[0044] A kind of hemostatic powder, its preparation comprises the steps:

[0045] 1) Preparation of etherified starch: Dissolve 6g of cornstarch in 200mL of deionized water, 4g of sodium hydroxide in 40mL of deionized water, and 40g of 2-chloroethyldiethylamine in 20mL of deionized water; The aqueous solution of 2-chloroethyldiethylamine and the aqueous solution of 2-chloroethyldiethylamine were added dropwise to the aforementioned cassava starch solution, and stirred and reacted at 60°C for 24 hours; 50-80% etherified starch;

[0046] 2) Weigh 0.7 g of the etherified starch obtained in the above step 1) and dissolve it in deionized water, stir evenly, and adjust the pH to 8 with sodium hydroxide to obtain a starch suspension;

[0047] 3) Measure 100mL of n-heptane, add 2.34g of Span 80, and emulsify to obtain a mixed solution;

[0048] 4) Add the starch suspension obtained in step 2) to the mixed solution obtained in step 3), then add 0.3 g of sodium tripolyphosphate, and r...

Embodiment 3

[0051] A kind of hemostatic powder, its preparation comprises the steps:

[0052] 1) Measure 100mL of n-hexane, add 2.34g of Span 80 to emulsify; weigh 0.5g of potato starch and dissolve it in deionized water, then add it to the cyclohexane mixture, add 0.3g of epichlorohydrin, and react at 25°C for 5 Hour;

[0053] 2) Product collection: after the reaction, dry under reduced pressure to remove n-hexane, wash the product with absolute ethanol, vacuum dry, grind, and sterilize to obtain starch hemostatic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com