Method for preparing polyether polyol in recycling manner by aid of DMC (double metal cyanide) catalyst

A technology of DMC catalyst and polyether polyol, which is applied in the field of preparing target polyether polyol, can solve the problems of wide product molecular weight distribution, increase production cost, slow reaction speed, etc., so as to reduce the discharge of filter residue and waste water, and reduce material loss. , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

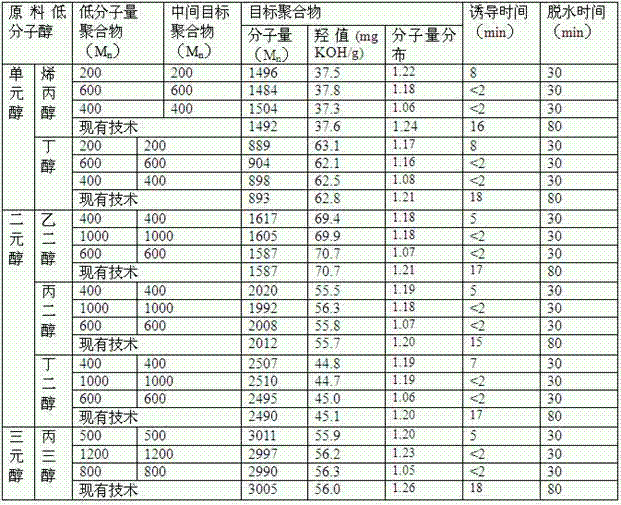

[0050] Example 1 : From the initiator propylene glycol polyoxypropylene ether (M n =600) and propylene glycol for the first time to prepare intermediate target polymer propylene glycol polyoxypropylene ether (M n =600)

[0051] 1) Add 2200Kg propylene glycol polyoxypropylene ether (M n =600) Initiator (can be prepared by traditional KOH catalyst, K, Na ions < 5ppm mixed with 66g of concentrated sulfuric acid in advance), add 402g of DMC catalyst, start stirring, vacuumize and heat up after nitrogen replacement, turn on the external circulation pump, At a temperature of 135-145°C and a pressure below -0.095Mpa, vacuum blow nitrogen for 60 minutes to dehydrate, turn off the nitrogen, and then vacuumize for 20 minutes.

[0052] 2) Close the vacuum valve, stop the vacuum, and feed 176Kg of propylene oxide. After 15 minutes of feeding, the pressure in the kettle drops obviously, and the temperature rises obviously, indicating that the reaction has started.

[0053] 3) Keep...

Embodiment 2

[0055] Example 2 : By the target intermediate polymer propylene glycol polyoxypropylene ether (M n =600) Propylene Glycol Polyoxyethylene / Propylene Ether (M n =2000)

[0056] 1) Add 2400Kg of the intermediate target polymer propylene glycol polyoxypropylene ether (M n =600) as the starter, add 120g of DMC catalyst, start stirring, vacuumize and raise the temperature after nitrogen replacement, turn on the external circulation pump, and vacuum for 30min at a temperature of 135-145°C and a pressure below -0.095Mpa.

[0057] 2) Close the vacuum valve, stop the vacuum, and feed 192Kg of alkylene oxide mixture (ethylene oxide / propylene oxide is 2:8). During the feeding process, the temperature rises obviously, indicating that the reaction has started.

[0058] 3) Keep the temperature at 130-135°C and the pressure below 0.02Mpa, and continue to feed 5408Kg of alkylene oxide mixture (ethylene oxide / propylene oxide is 2:8). After 160 minutes, the feeding of the alkylene oxide...

Embodiment 3

[0060] Example 3 : By the intermediate target polymer propylene glycol polyoxypropylene ether (M n =600) and propylene glycol circulation to prepare target intermediate polymer propylene glycol polyoxypropylene ether (M n =600)

[0061] 1) Add 1800Kg of the intermediate target polymer propylene glycol polyoxypropylene ether (M n =600) as the starter (pre-mixed with 54g of concentrated sulfuric acid), add 310g of DMC catalyst, start stirring, vacuumize and heat up after nitrogen replacement, turn on the external circulation pump, at a temperature of 135~145°C and a pressure of -0.095Mpa The following vacuum 30min.

[0062] 2) Close the vacuum valve, stop the vacuum, and feed 144Kg propylene oxide. During the feeding process, the temperature rises obviously, indicating that the reaction has started.

[0063] 3) Keep the temperature at 150-160°C and the pressure below -0.02Mpa. At the same time, continuously add 3645kg propylene oxide and 785kg propylene glycol (pre-mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com