Anti-acid concrete for manufacturing top pipe

A concrete and acid-resistant technology, applied in the field of acid-resistant concrete, can solve problems such as corrosion and cracks, and achieve the effect of high water resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

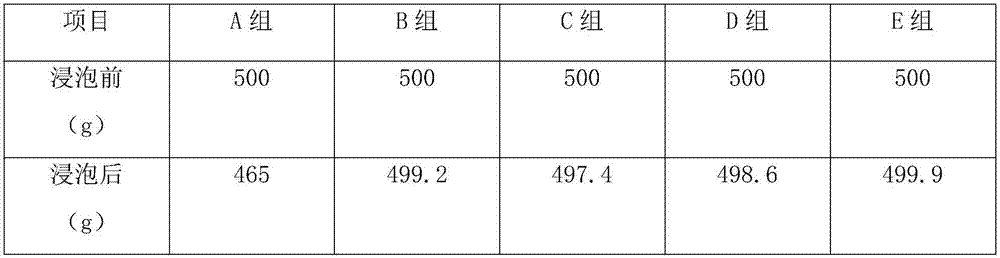

[0022] Choose the pipe jacking made of ordinary concrete, destroy the pipe jacking, take 500g pipe jacking block, put it into the simulated acidic soil test solution, the pH of the acidic soil test solution is 5-6, and extract it from the southeast hilly red soil, soak 1 piece Month, weigh again, statistical weight data, marked as A.

Embodiment 2

[0024] The pipe jacking prepared by the following ratio is selected, and the concrete is composed of the following weight ratio, 43 parts of coal gangue, 25 parts of limestone, 16 parts of calcium lignosulfonate, 17 parts of borax, 39 parts of calcium sulfate, and 25 parts of calcium carbonate. Destroy the pipe jacking, take 500g pipe jacking block, put it into the simulated acidic soil test solution, the pH of the acidic soil test solution is 5-6, it is obtained by leaching from the southeast hilly red soil, soak for 1 month, weigh again, and calculate the weight data , labeled B.

Embodiment 3

[0026] The pipe jacking prepared by the following ratio is selected, and the concrete is composed of the following weight ratio: 35 parts of coal gangue, 20 parts of limestone, 9 parts of calcium lignosulfonate, 13 parts of borax, 30 parts of calcium sulfate, and 19 parts of calcium carbonate. Destroy the pipe jacking, take 500g pipe jacking block, put it into the simulated acidic soil test solution, the pH of the acidic soil test solution is 5-6, it is obtained by leaching from the southeast hilly red soil, soak for 1 month, weigh again, and calculate the weight data , labeled C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com