Inflation-free solid tire

A solid tire and air-free technology, which is applied in the direction of non-pneumatic tires, special tires, tire parts, etc., can solve the problem of not being wear-resistant but has good and suitable elastic polyurethane body, poor control of polyurethane production process, increased process and cost and other issues, to achieve the effect of saving resources, convenient application and use, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

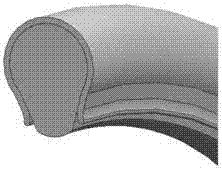

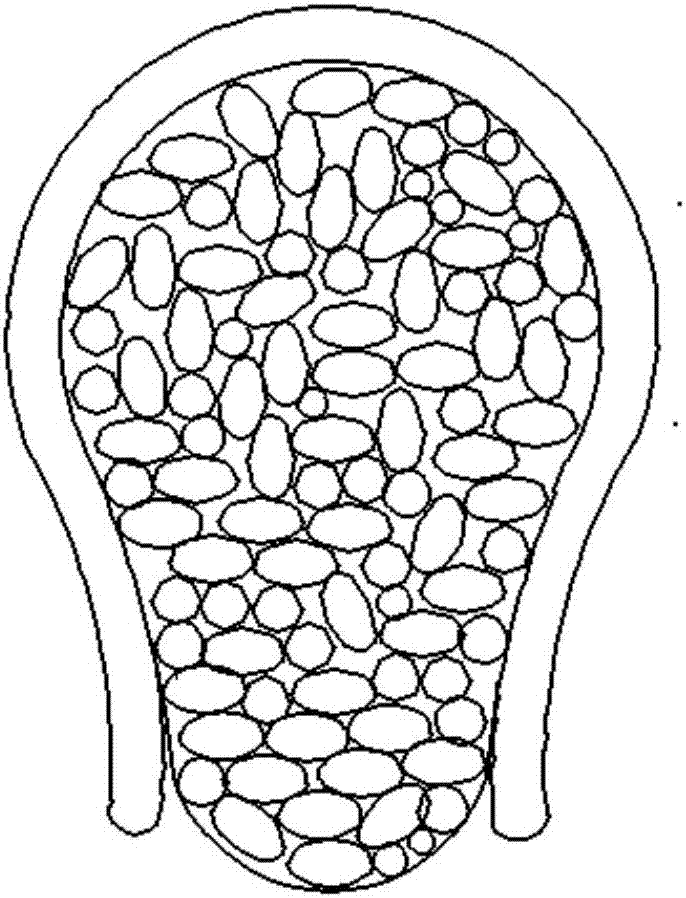

Embodiment 1

[0031] The inner molding chamber of the tire mold is filled with supercritical carbon dioxide foam to obtain a density of 0.16g / cm 3 Polyester thermoplastic polyurethane foamed particles, close the mold, pass high-temperature steam of 0.2MPa and 150°C, heat and shape for 3 minutes, then pour in condensed water to cool and dry to shape, and finally obtain a non-inflatable solid tire core; The tire core is installed inside the existing rubber tire; finally, the assembled tire is installed on the rim with tools, so as not to inflate the solid tire.

Embodiment 2

[0033] The inner molding chamber of the tire mold is filled with supercritical carbon dioxide foam to obtain a density of 0.23g / cm 3 The polyether-type thermoplastic polyurethane foamed particles, closed the mold, passed the high temperature steam of 0.2MPa and 150°C, kept the shape for 3 minutes, then passed the condensed water to cool and dry to shape, and finally obtained the non-inflatable solid tire core; The tire core is installed inside the existing rubber tire; finally, the assembled tire is installed on the rim with tools, so as not to inflate the solid tire.

Embodiment 3

[0035] The inner molding chamber of the tire mold is filled with supercritical carbon dioxide foam to obtain a density of 0.14g / cm 3 Polyester thermoplastic polyurethane foamed particles, close the mold, pass high-temperature steam of 0.2MPa and 150°C, heat and shape for 3 minutes, then pour in condensed water to cool and dry to shape, and finally obtain a non-inflatable solid tire core; The tire core is installed inside the existing rubber tire; finally, the assembled tire is installed on the rim with tools, so as not to inflate the solid tire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com