An online autocatalytic denitrification device for sintering dust

A self-catalysis and denitration technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of occupying catalyst surface active points, accelerating catalyst pore blockage, accelerating catalyst poisoning effect, etc., and saving denitration equipment investment. , the effect of increasing the catalyst concentration and reducing the cost of denitration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

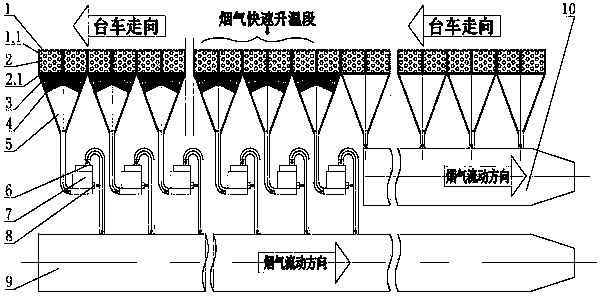

[0028] Example 1: see figure 1 , including a sintering machine 1, a bellows 5 is arranged under the trolley 1.1 of the sintering machine 1, and the outlet at the bottom of the bellows 5 is connected to the main flue, and the sintering machine 1 is sequentially divided into ignition section, head section, There are 4 areas of the flue gas rapid heating section and the tail section, and the bellows 5 below the tail section to the flue gas rapid heating section area are equipped with liquid ammonia nozzles 3. The liquid ammonia nozzle 3 is located on the upper part of the bellows 5, and is arranged along the circumferential direction of the side wall of the bellows 5, and the nozzle outlet is inclined upward. The main flue is composed of a high temperature flue gas main flue 9 and a low temperature flue gas main flue 10 . The outlet of the bellows 5 below the tail section and the rapid heating section of the flue gas is connected to the main flue 4 of high temperature flue gas t...

Embodiment 2

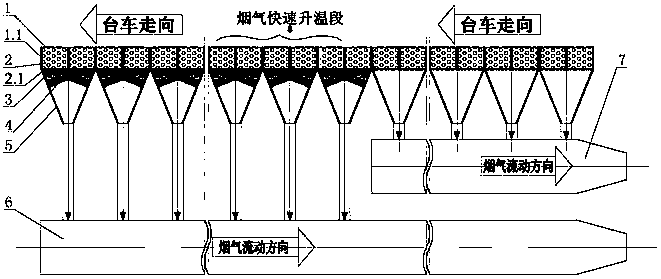

[0043] see figure 2 , without the fluidized bed reactor 7, the sintered flue dust is directly sent into the high temperature flue gas main flue 9 without passing through the fluidized bed reactor 7, and the rest are the same as in Example 1.

Embodiment 3

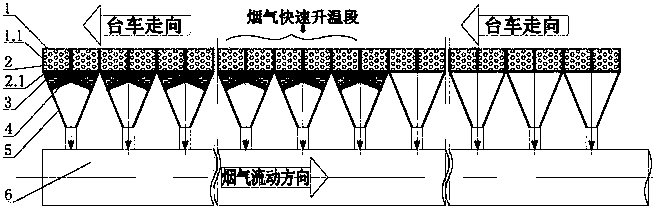

[0045] see image 3 , without the low temperature flue gas main flue 10 and the fluidized bed reactor 7, all the sintered soot in the bellows 5 is directly fed into the high temperature flue gas main flue 9, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com