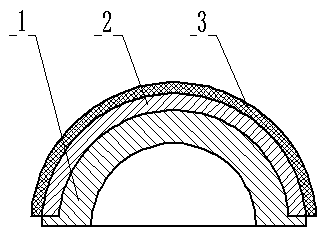

an acetabular cup

An acetabular cup and multi-stage hole technology, applied in the field of artificial acetabular cup, can solve the problems of unfavorable acetabular cup and surrounding bone fusion, difficulty in meeting the functional requirements of acetabular cup, unfavorable tissue growth into acetabular cup, etc., to achieve The effect of avoiding hip joint repair, overcoming interface instability, and relieving patients' pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the acetabular cup lining material is made of ultra-high molecular weight polyethylene (UHMWPE), the backing is made of metal titanium, and the porous material on the backing is made of a porous cobalt-based alloy material CoCrMo with a secondary pore structure, and the uniformly distributed first-level The pore diameter of the cavity is 120µm-400µm, and there are evenly distributed second-stage cavities on the wall of the first-stage cavity, that is, the wall of the first-stage cavity is composed of evenly distributed second-stage cavities. Made of metal material, the pore diameter of the second-stage cavity is 400nm-630nm, the first-stage cavity and the second-stage cavity are connected to each other, and the first-stage cavity and the second-stage cavity are also connected to each other. The acetabular cup preparation method is:

[0025] (1) Preparing the titanium backing blank by hot stamping, and then rough machining to obtain the rough machinin...

Embodiment 2

[0035] An acetabular cup, the lining material of the acetabular cup is polyetheretherketone (PEEK), the backing is made of metallic niobium, and the porous material on the backing is made of multi-stage porous niobium, and the multi-stage porous niobium has a two-stage pore structure. The pore diameter of the primary cavity is 900µm-1500µm, the pore diameter of the secondary cavity is 400nm-700nm, and the structure and preparation method are similar to those in Example 1.

[0036] The first-stage porosity of this kind of porous niobium is 80%, the elastic modulus is 3.2GPa, the second-stage porosity is 41%, the elastic modulus is 79GPa, and the overall elastic modulus is 2.7GPa.

Embodiment 3

[0038] In this embodiment, the lining material of the acetabular cup is made of ultra-high molecular weight polyethylene (UHMWPE), the backing is made of metal titanium, and the porous material on the backing is made of multi-level porous tantalum. The multi-level porous tantalum has a three-level pore structure. There are evenly distributed and interpenetrating second-level cavities on the wall of the distributed and interpenetrating first-level cavities (that is, the largest-level cavities), and there are evenly distributed and inter-penetrating cavities on the cavity walls of the second-level cavities. The third-level cavity (that is, the smallest-level cavity); and the cavities of each level are also connected to each other. The pore size of the first stage is 460µm-620µm, the porosity is 88%, the pore size of the second stage is 48µm-80µm, the porosity is 73%, the pore size of the third stage is 340nm-480nm, the porosity is 62% . The acetabular cup preparation method is:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com