Tritium target apparatus

A technology of target device and target sheet, which is applied in the field of ion beam bombardment device, and can solve the problems of target sheet diameter, rotational speed, mechanical strength, and sealing technology limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

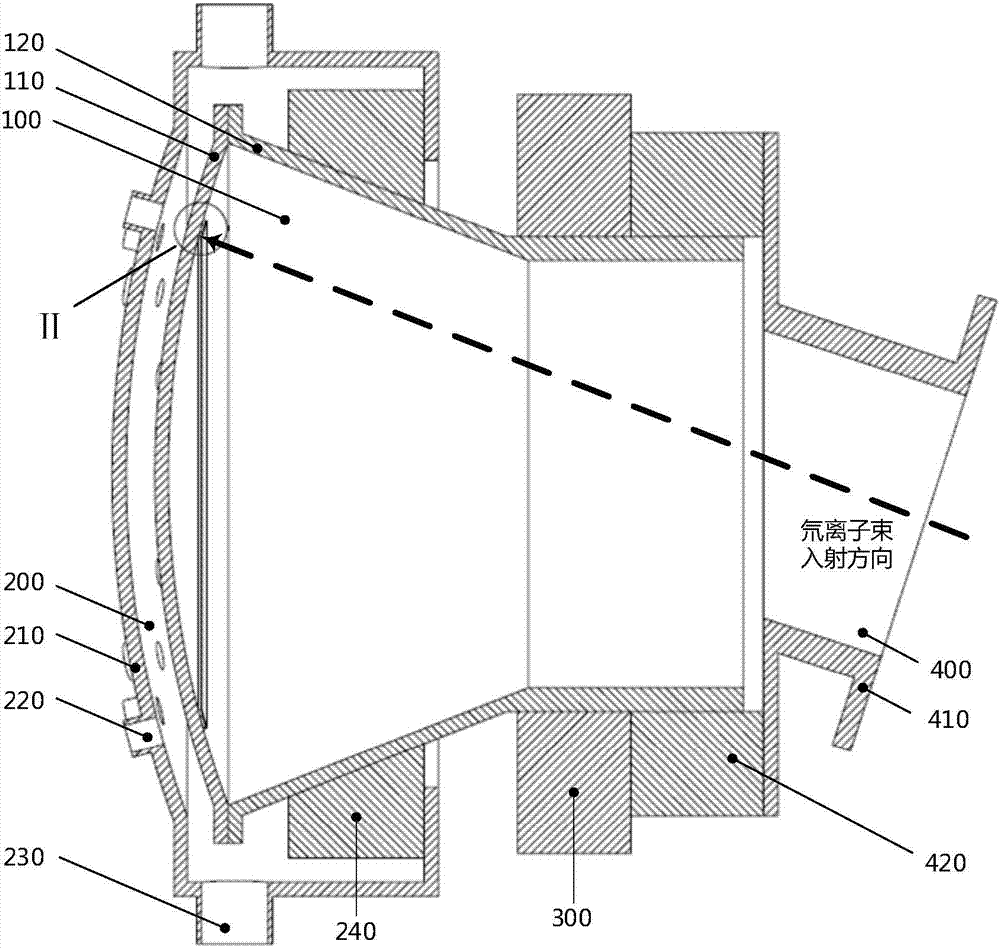

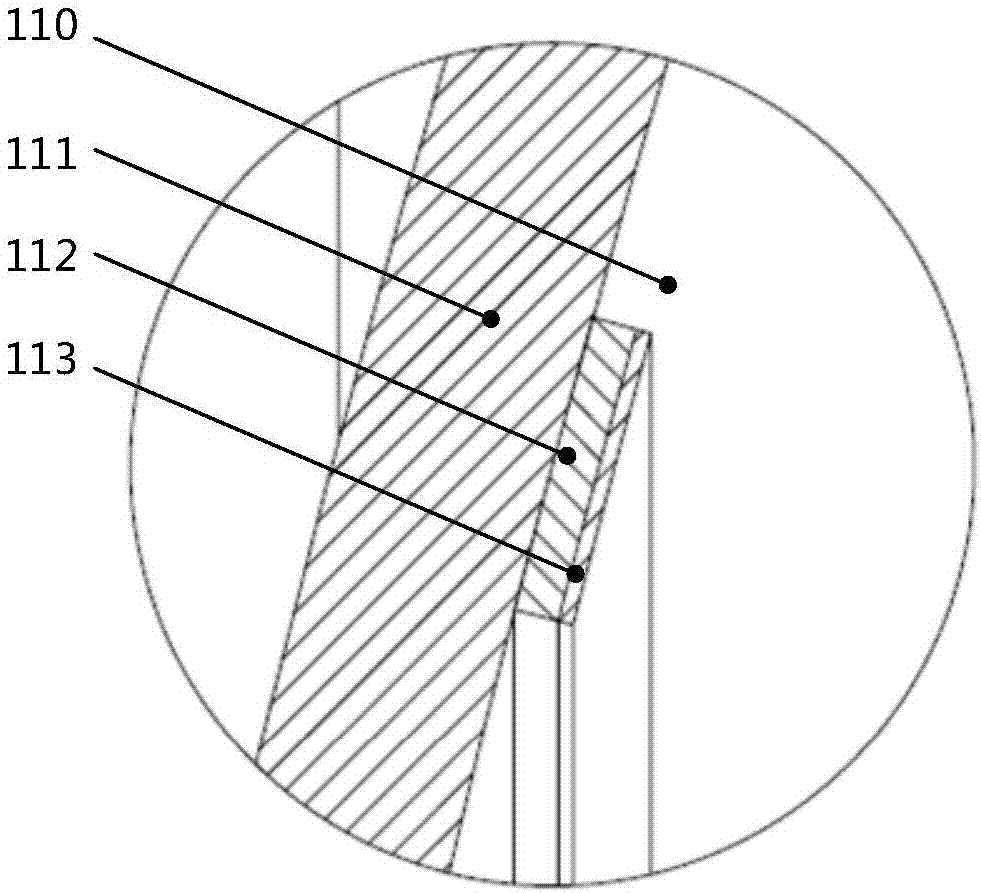

[0010] see figure 1 with figure 2 , figure 1 It is a schematic cross-sectional structure diagram of a tritium target device in an embodiment, wherein the incident direction of the deuterium ion beam of the deuterium ion beam is also shown, figure 2 for figure 1 Schematic diagram of the enlarged structure of part II of the tritium target device shown.

[0011] In this embodiment, the tritium target device includes but not limited to a target body 100 and an accelerator interface 400, the target body 100 includes a target piece 110, and the target piece 110 includes a base 111 and is provided on the base 111 with A diamond layer 112 with high thermal conductivity, wherein when the deuterium ion beam flows through the accelerator interface 400 and shoots into the target 110, the heat energy released is absorbed and diffused by the diamond layer 112 and transferred to the substrate 111 .

[0012] It should be noted that the minimum structure of the tritium target device in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com