Dry-type multi-channel gas purification tower and working method thereof

A multi-channel, purification tower technology, applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve problems such as difficult gas sealing, short circuit, long sealing surface of purifier basket, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

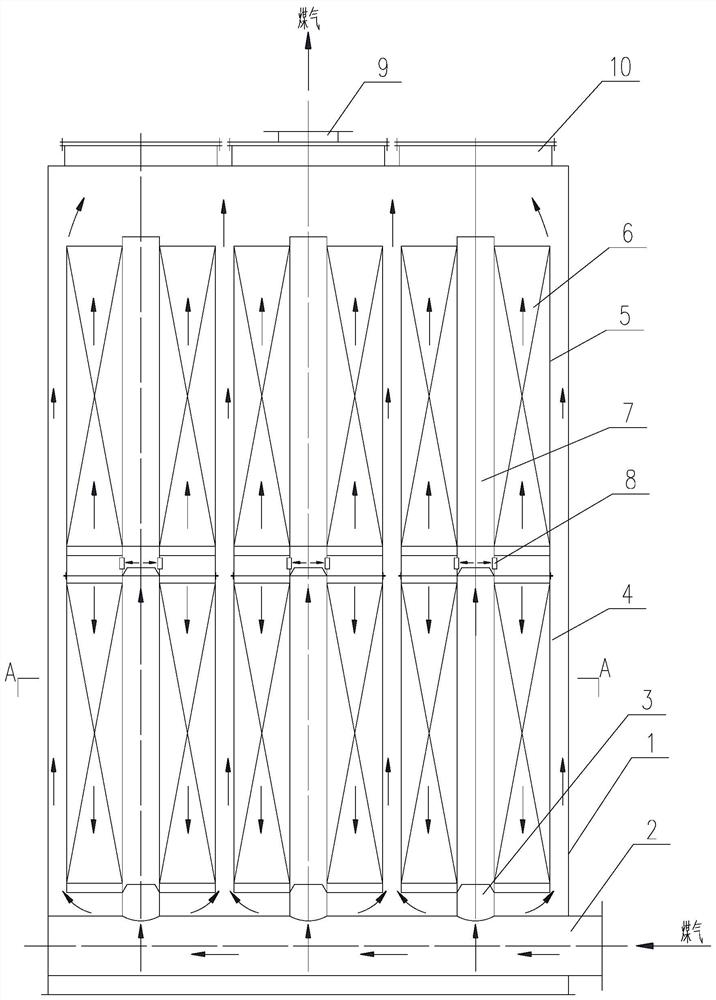

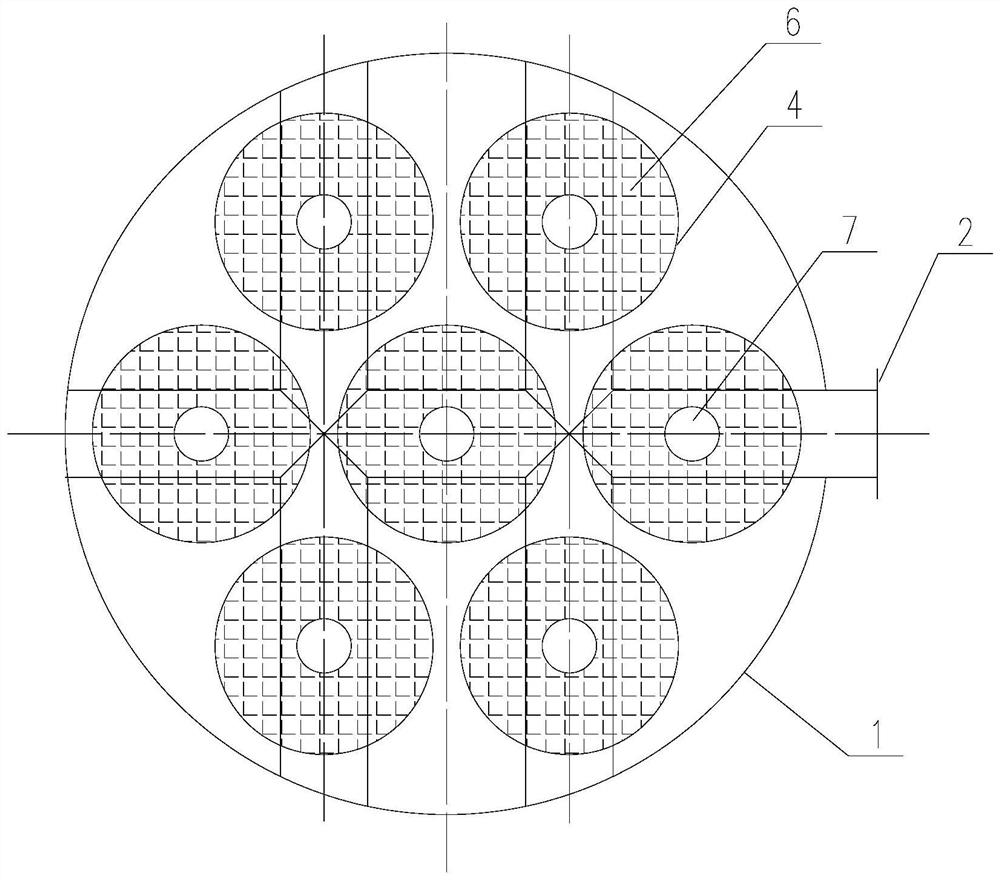

[0024] Such as figure 1 , figure 2 As shown, a dry multi-channel gas purification tower according to the present invention includes a tower body 1, a gas inlet pipe 2 and multiple groups of purifying agent columns; the tower body 1 is a closed tower body, and multiple groups of purifying agent columns are installed In the tower body 1, and evenly distributed along the cross section of the tower body 1; each group of purifier columns includes a central tube 7, an upper purifier ring 5 and a lower purifier ring 4, and the upper purifier ring 5 and the lower purifier ring 4 are respectively It consists of an annular cylinder and a purifier 6 filled in the annular cylinder. The annular cylinder is set on the outside of the central tube 7; there is an air intake space between the upper purifier ring 5 and the corresponding lower purifier ring 4 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com